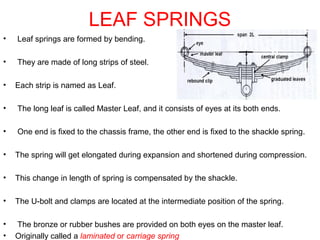

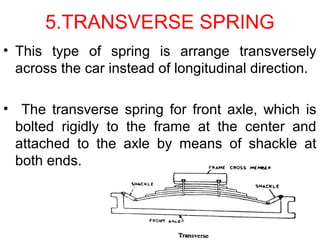

The document discusses different components of a vehicle's suspension system. It begins by defining sprung mass and unsprung mass. Sprung mass refers to parts of the vehicle supported by the suspension, like the body and frame. Unsprung mass includes components below the suspension like wheels. The document then covers various types of springs used in suspension systems, including leaf springs, coil springs, rubber springs, and torsion bars. It also discusses shock absorbers and their purpose of controlling spring motion. Finally, the key functions of a suspension system are outlined as isolating the vehicle from road shocks and providing stability, comfort, and road handling ability.