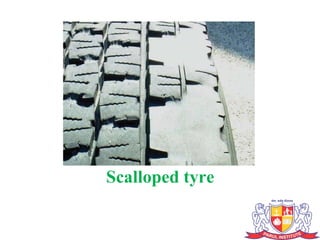

Pratik L Malusare's document discusses wheel balancing. It defines wheel balancing as adding weights to a wheel rim to evenly distribute mass and prevent vibrations. Reasons to balance wheels include steering wheel vibration and tire cupping at highway speeds. The document describes dynamic balancing machines that spin wheels at high RPM to measure imbalance, and how adding weights at specific locations corrects imbalance, improving ride comfort and reducing component wear.