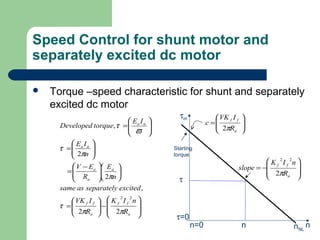

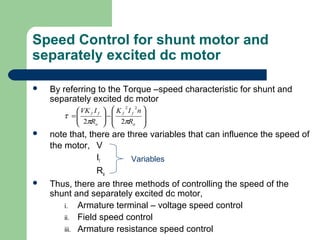

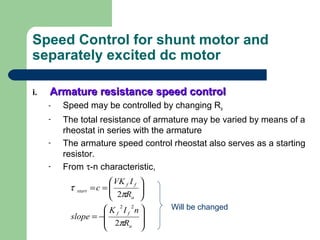

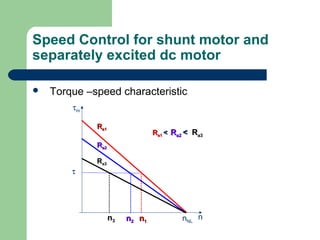

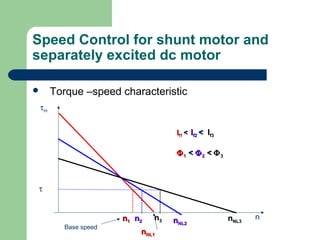

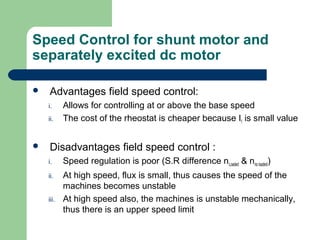

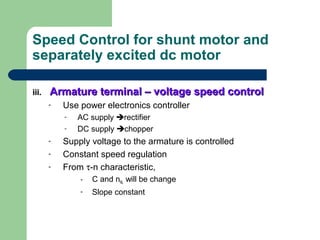

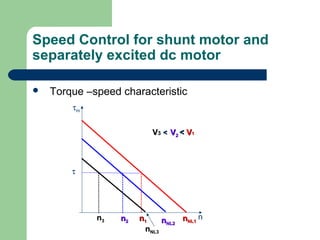

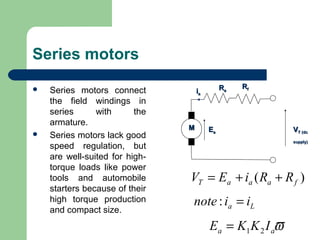

This document discusses direct current (DC) motors. It describes the construction and operating principles of different types of DC motors including series, shunt, compound and permanent magnet motors. It also discusses speed control methods for shunt and separately excited DC motors. The main methods of speed control are armature voltage control, field control and armature resistance control. Armature resistance control is simple but less efficient while field control provides better speed regulation.

![Series Motor (cont)

Example 1:

A dc machine in Figure 1 is

consumed a 6.5kW when the

12.5 A of armature current is

passing thru the armature and

field resistance of 3.3Ω and 2.0Ω

respectively. Assume stray

losses of 1.2kW. Calculate

a) terminal voltage, VT

b) back emf, Ea

c) net torque if the speed is at

3560rpm

d) efficiency of the machine

[520V, 453.75V, 12N-m, 68.8%]

EEaa

RRff

MM VVT (dcT (dc

supply)supply)

RRaaiiaa

Figure 1](https://image.slidesharecdn.com/chapter2-2typesofdcmotor-160130074901/85/Types-of_dc_motor-9-320.jpg)

![Series Motor (cont)

Example 2:

A 600V 150-hp dc machine in

Figure 2 operates at its full rated

load at 600rpm. The armature and

field resistance are 0.12Ω and

0.04Ω respectively. The machine

draws 200A at full load. Assume

stray losses 1700W. Determine

a) the armature back emf at full load,

Ea

b) developed/mechanical power and

developed/mechanical torque

c) assume that a change in load

results in the line current dropping

to 150A. Find the new speed in

rpm and new developed torque.

{Hint: Ea=K1K2iaω}

EEaa

RRff

MM VVT (dcT (dc

supply)supply)

RRaaiiaa

Figure 2

[568V, 113.6kW, 1808Nm, 811.27rpm, 1017Nm]](https://image.slidesharecdn.com/chapter2-2typesofdcmotor-160130074901/85/Types-of_dc_motor-10-320.jpg)

![Shunt Motor

Example :

– A voltage of 230V is applied to armature of a

machines results in a full load armature currents

of 205A. Assume that armature resistance is

0.2Ω. Find the back emf, net power and torque by

assuming the rotational losses are 1445W at full

load speed of 1750rpm.

[189V, 37.3kW, 203.5Nm]](https://image.slidesharecdn.com/chapter2-2typesofdcmotor-160130074901/85/Types-of_dc_motor-13-320.jpg)