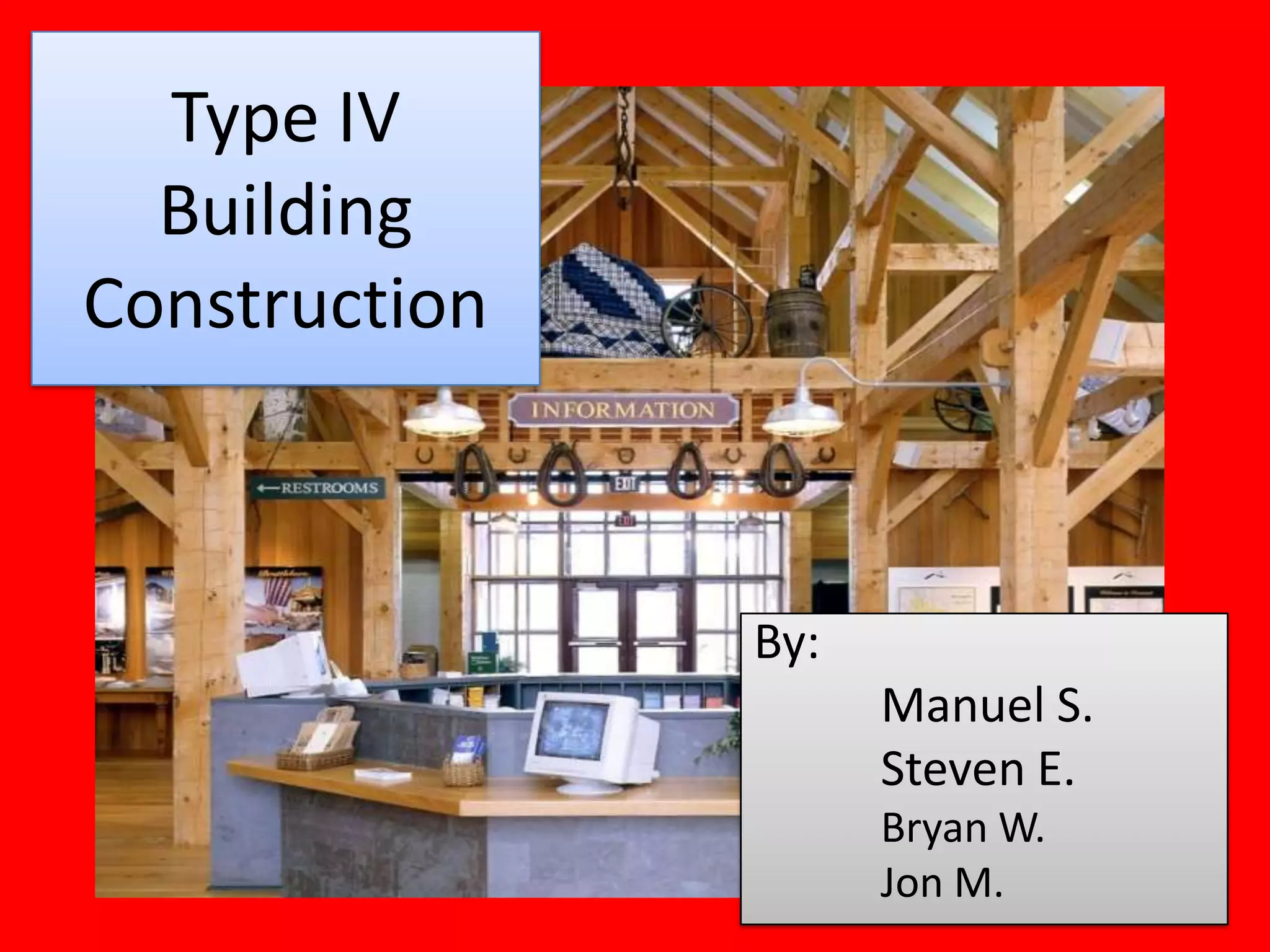

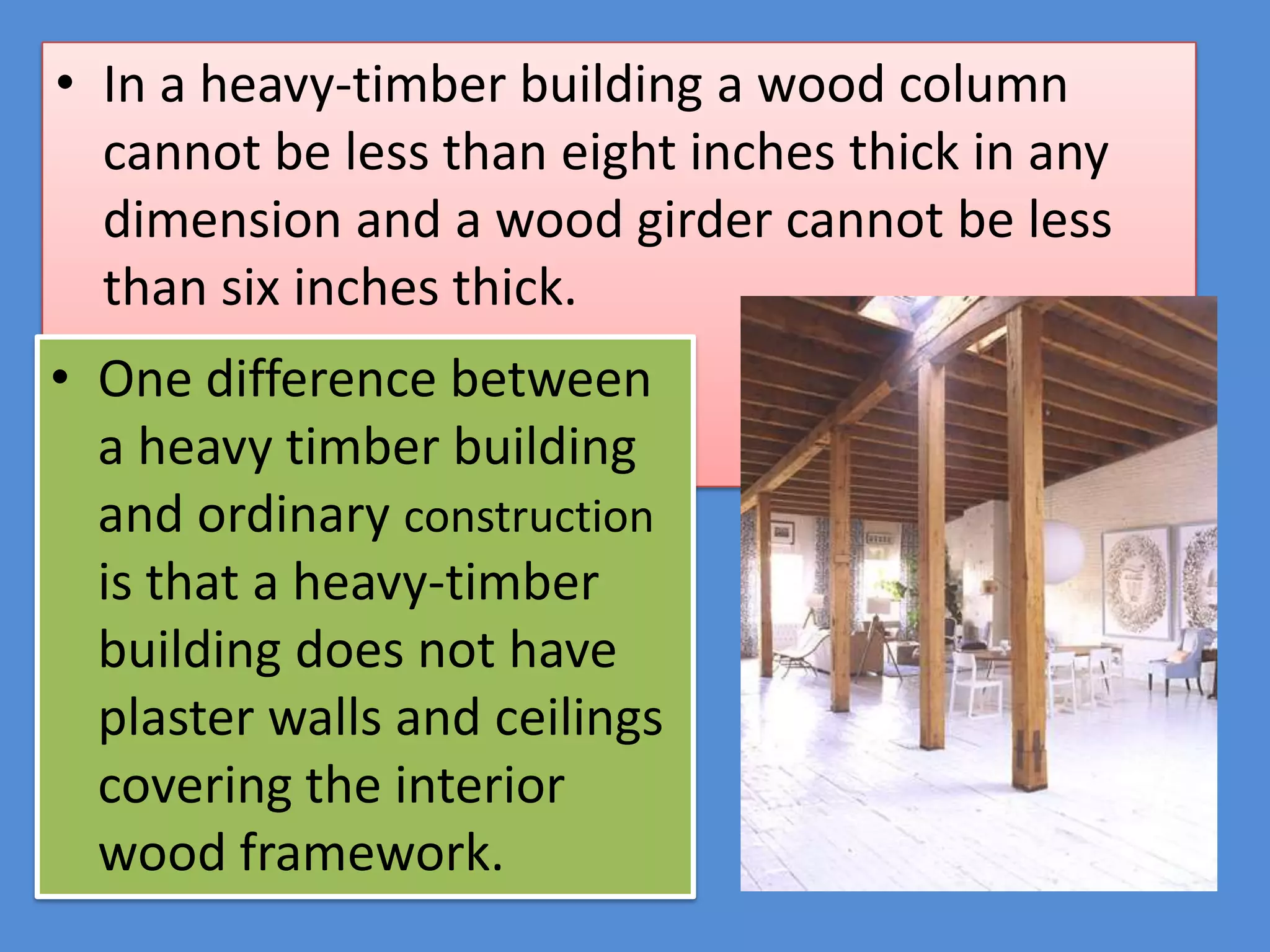

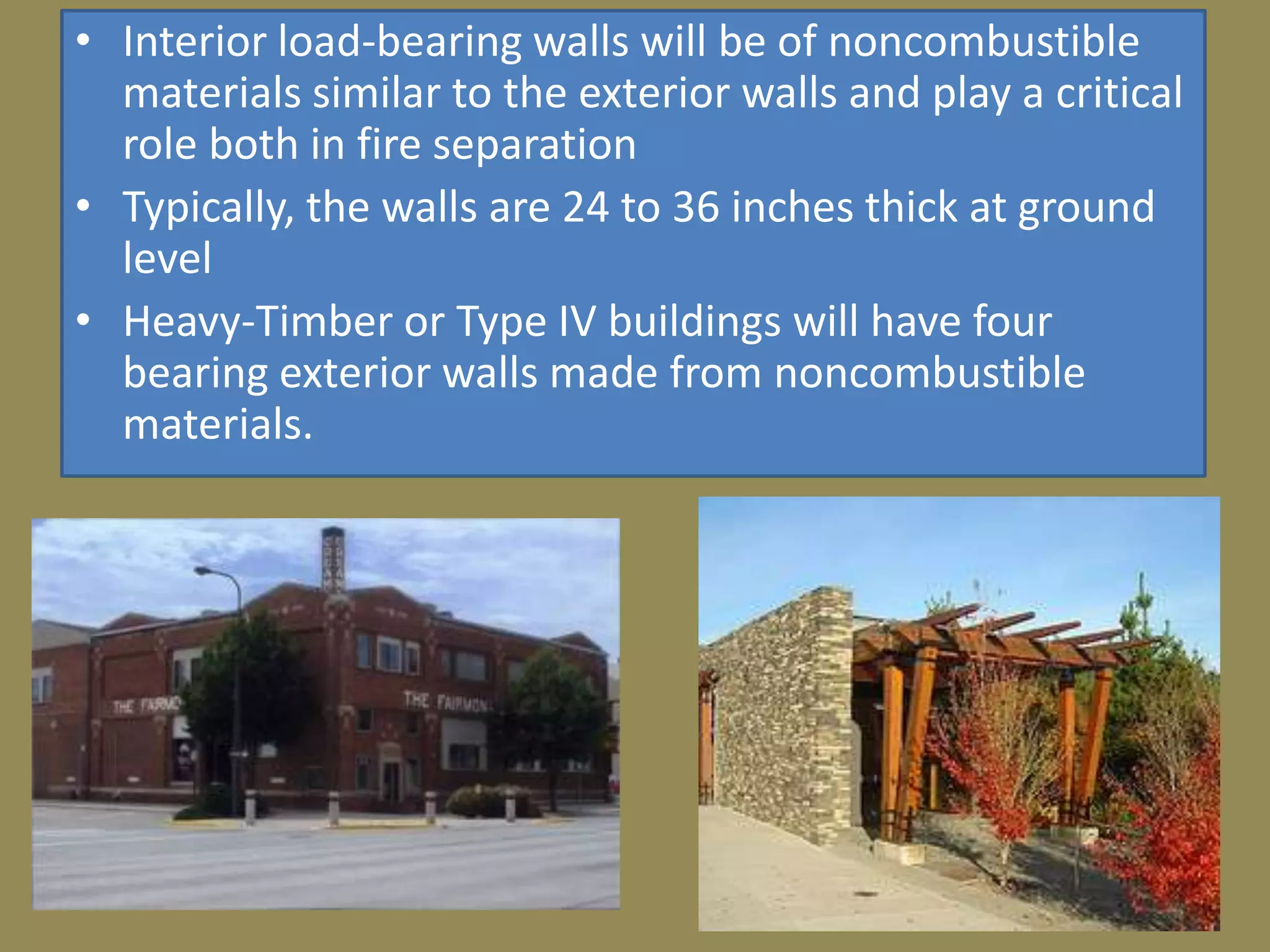

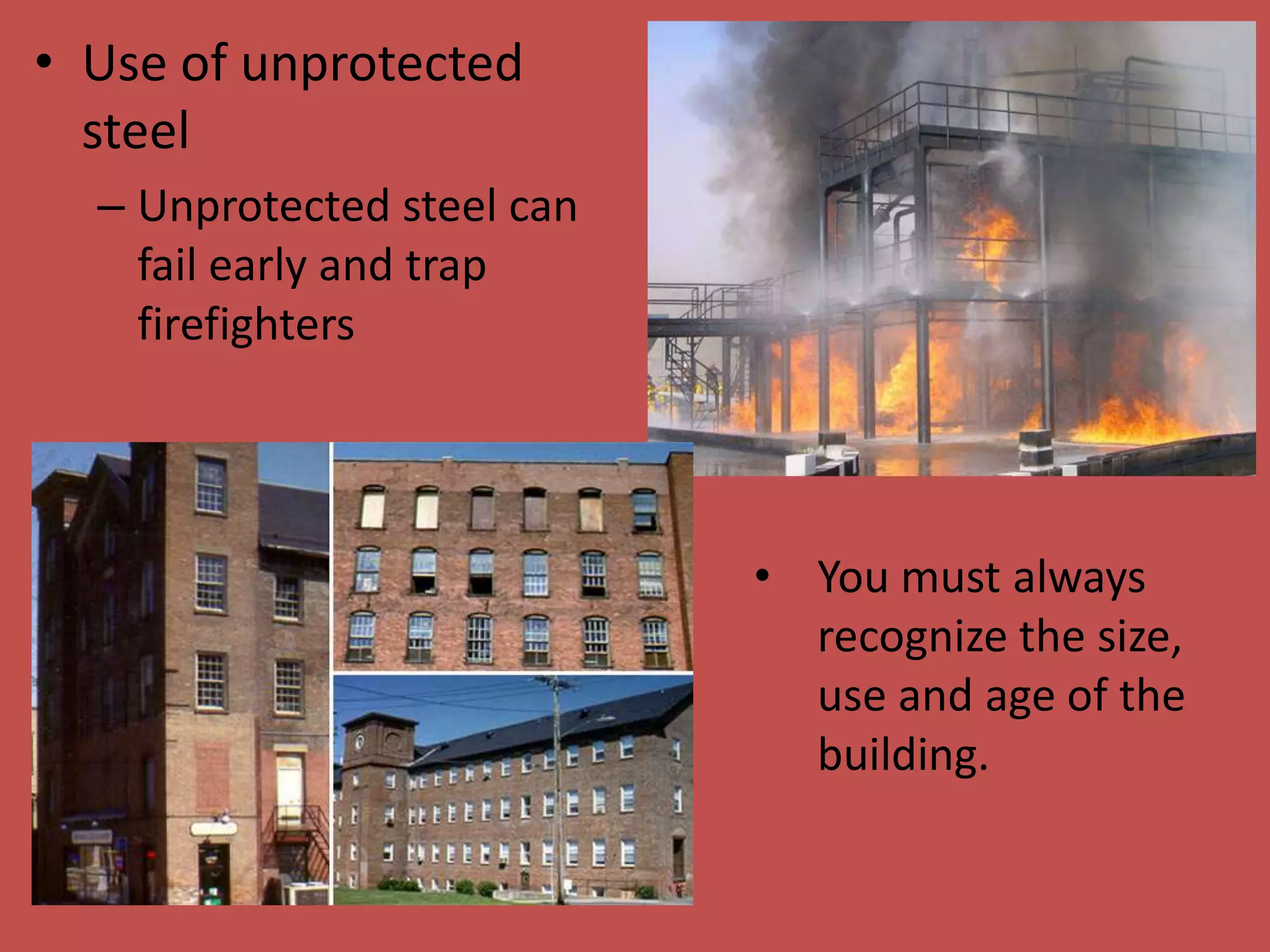

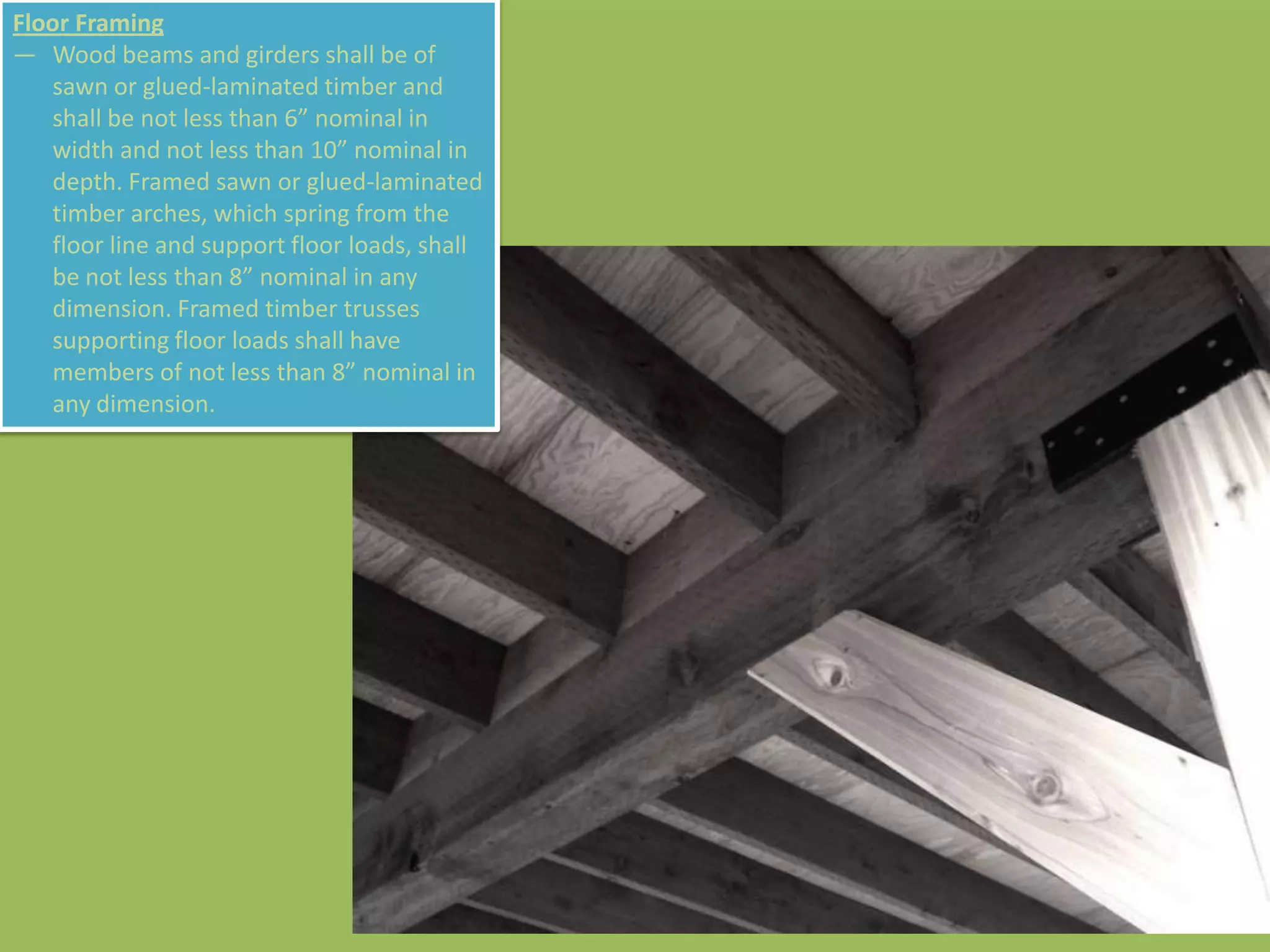

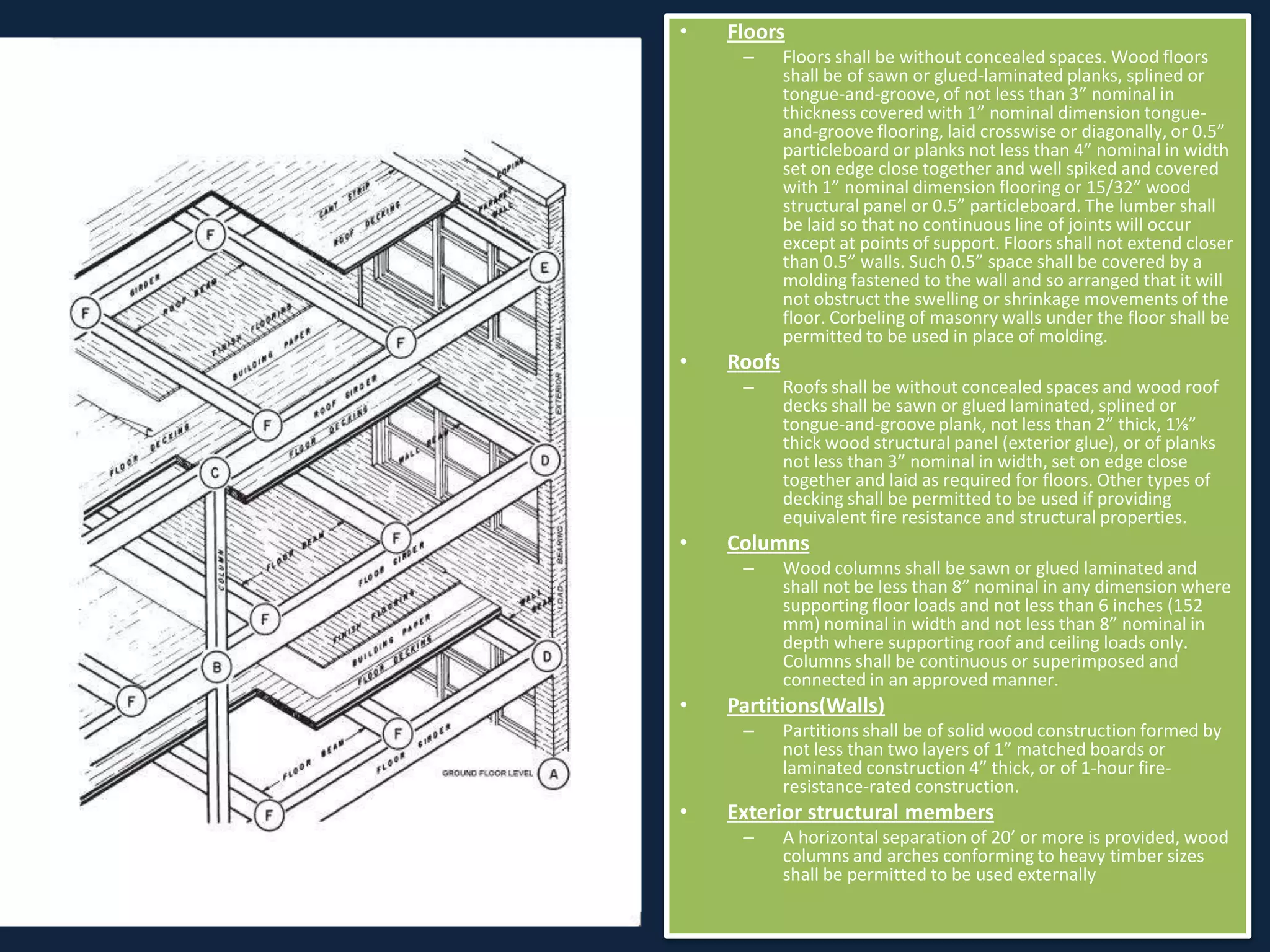

Type IV or heavy timber construction uses large dimensional lumber for structural elements like walls, floors, and roofs to provide fire resistance. It was commonly used in the late 19th/early 20th century for industrial and commercial buildings. Key features include wood columns no less than 8 inches thick, wood girders at least 6 inches thick, and floor/roof planks at least 2 inches thick. Interior walls are also fire-resistant. This construction type is beneficial as it is stable during early-stage fires and the large timber sizes allow it to burn longer before collapse compared to other materials like steel.