This document provides information about a workshop practice course, including:

- Instructors Lt. Col. Rashid Iqbal Ansari and Lab Engr. Saqib Anwar

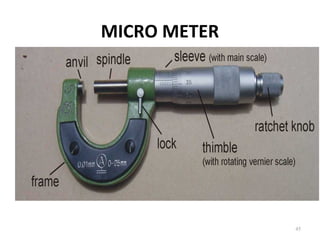

- Course objectives are to introduce workshop technologies, machine tools, and gain hands-on experience

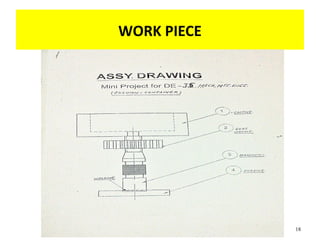

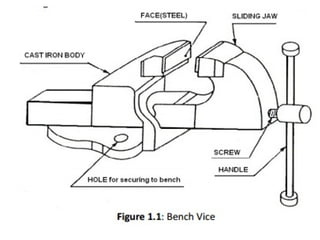

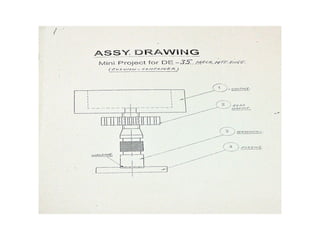

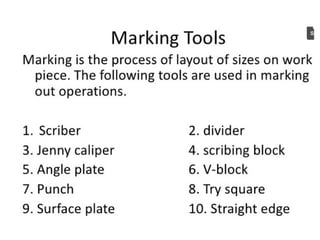

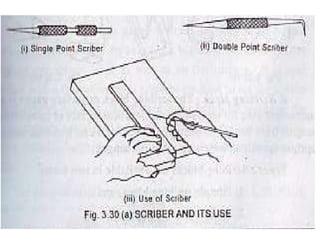

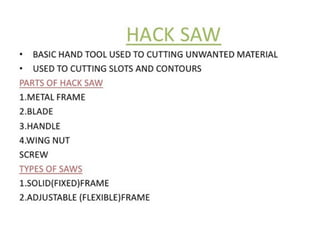

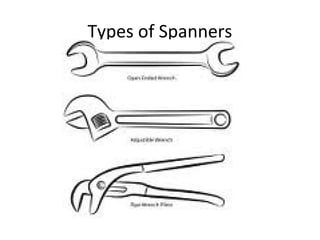

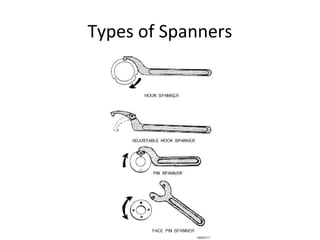

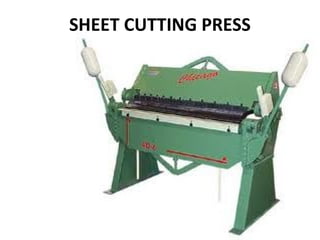

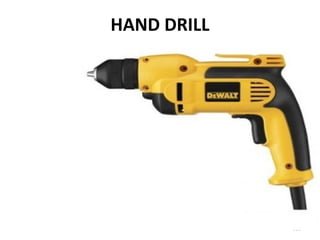

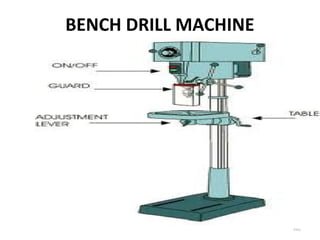

- Topics covered include woodworking, welding, machining, electroplating, forging, electric circuits, fitting and assembly, gear making, casting, and workshop safety

- Students will be evaluated through exams, quizzes, assignments, and a notebook