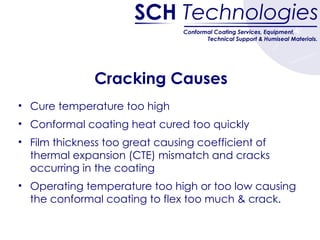

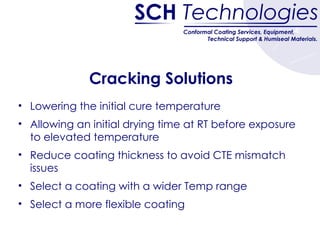

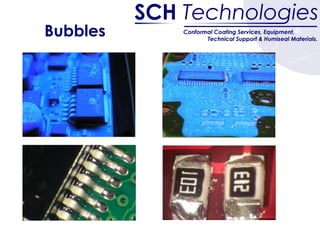

This document discusses common defects that can occur with conformal coatings, including capillary flow, de-wetting, delamination, cracking, corrosion, orange peel, and bubbles. It provides the root causes and solutions for each defect to help troubleshoot conformal coating process failures and prevent issues from reoccurring. Understanding the coating type, application method, curing process, and full coating process is important to identify the root cause of defects.