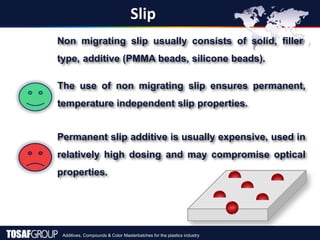

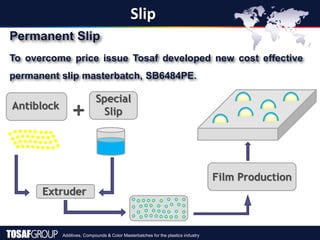

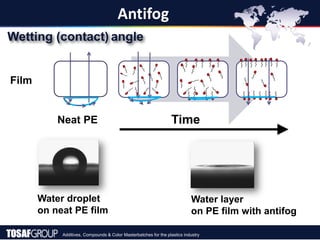

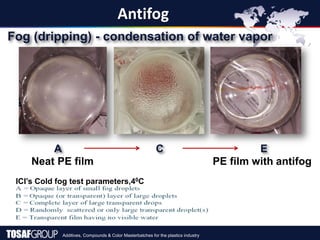

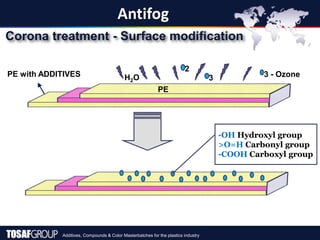

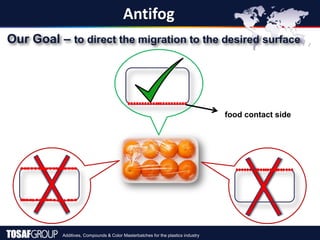

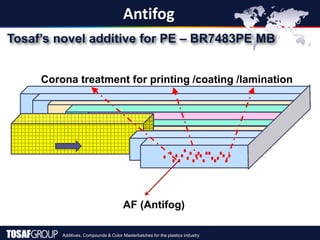

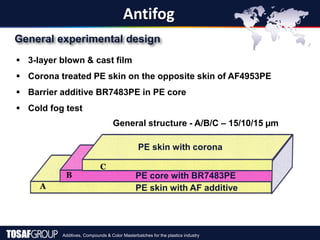

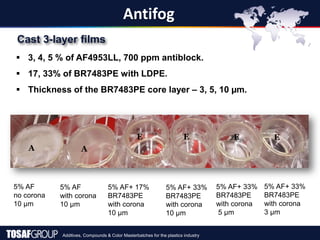

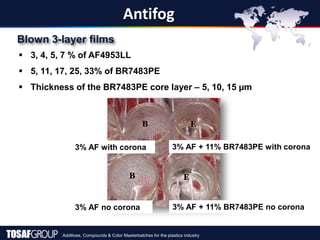

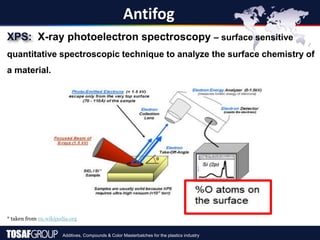

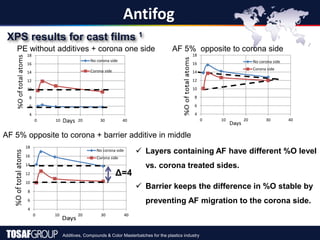

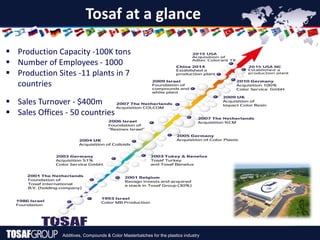

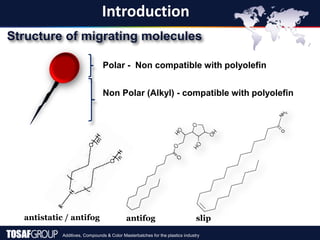

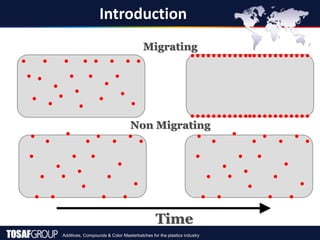

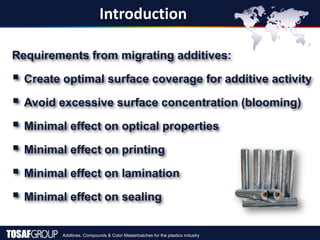

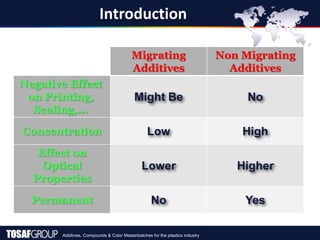

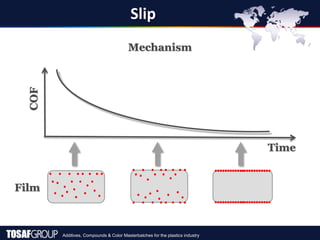

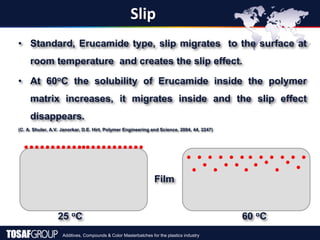

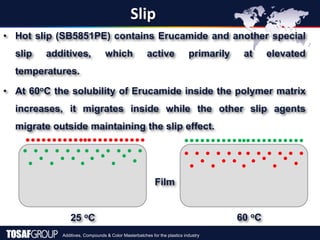

Tosaf is a leading manufacturer of additives, compounds, and color masterbatches for the plastics industry. The presentation discusses migrating vs. non-migrating additives, focusing on slip and antifog additives. For slip additives, migrating types work well at room temperature while hot slip additives maintain effectiveness at higher temperatures. Non-migrating slip provides permanent properties. For antifog films, directing the migration of antifog additives to the desired surface was explored using corona treatment and barrier additives in multilayer films. Experimental results showed the barrier additive prevented antifog migration. In summary, migrating and non-migrating additives both have advantages and migration control

![Additives, Compounds & Color Masterbatches for the plastics industry

Slip

0

0.5

1

1.5

2

20 30 40 50 60

COF

Temperature [oC]

Erucamide

Temperature Dependence](https://image.slidesharecdn.com/migratingvsnonmigratinginpolymer-210925013703/85/Migrating-vs-non-migrating-in-polymer-12-320.jpg)

![Additives, Compounds & Color Masterbatches for the plastics industry

Slip

0

0.5

1

1.5

2

20 30 40 50 60

COF

Temperature [oC]

Hot Slip

Erucamide

(SB5851PE)

Migrating Hot Slip Temperature Dependence](https://image.slidesharecdn.com/migratingvsnonmigratinginpolymer-210925013703/85/Migrating-vs-non-migrating-in-polymer-15-320.jpg)