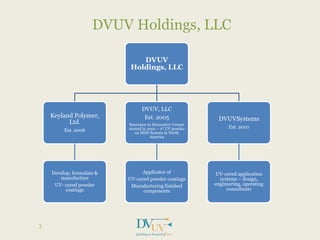

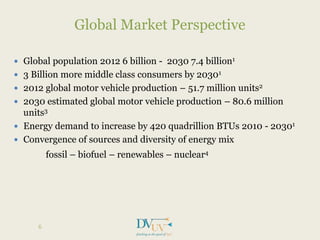

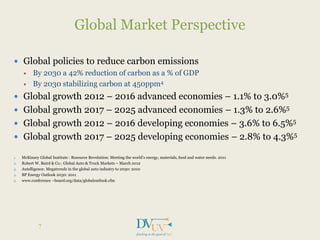

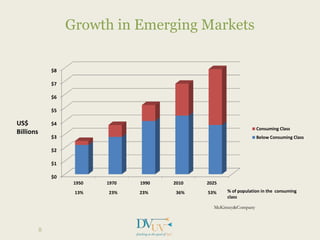

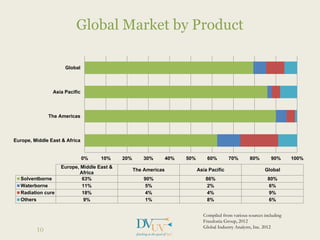

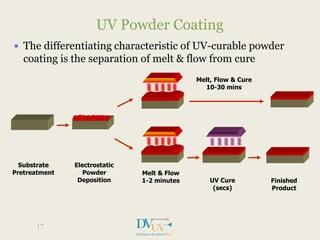

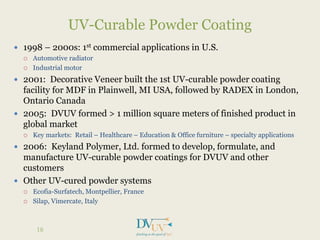

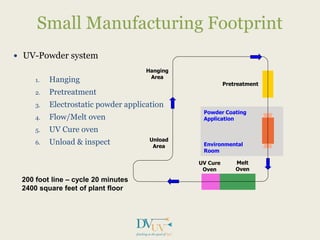

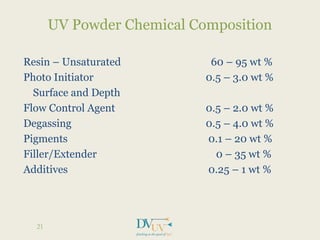

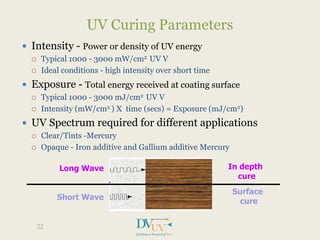

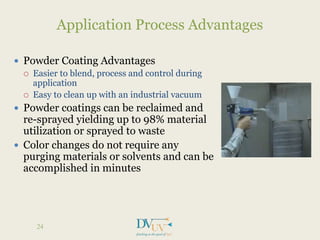

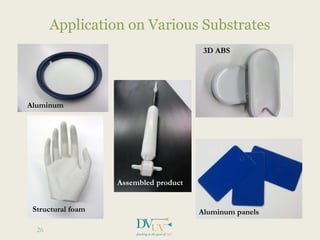

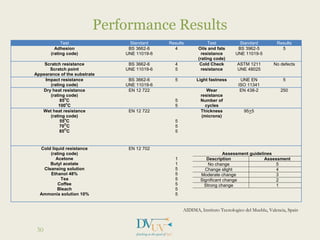

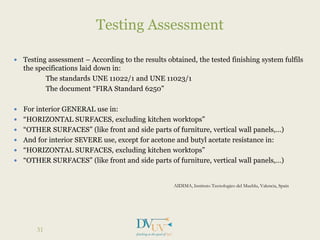

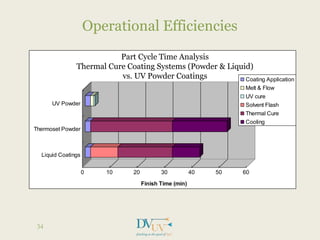

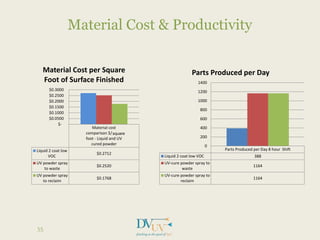

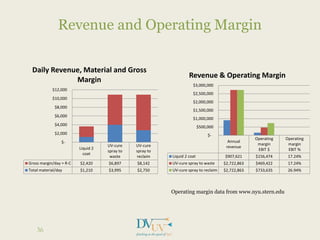

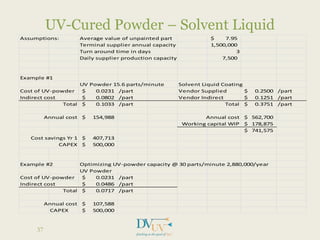

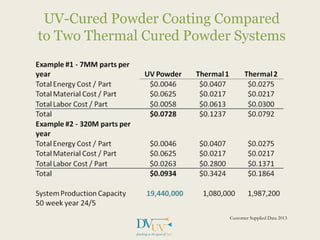

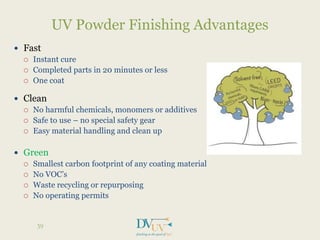

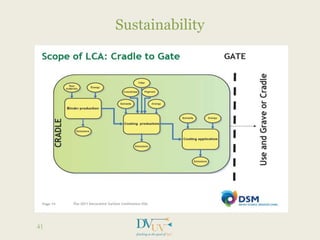

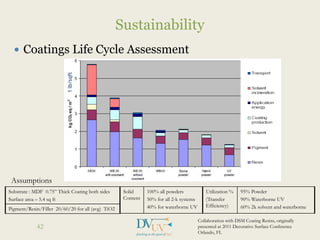

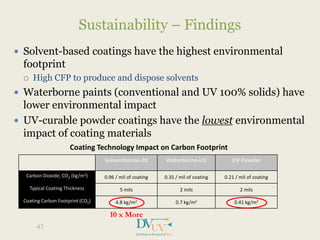

The document discusses the advancements and market potential of UV-curable powder coatings, highlighting their advantages in sustainability, operational efficiencies, and performance characteristics. It details the growth trends in the global coatings market, driven by increasing environmental concerns and consumer demand for quicker and cleaner applications. The report emphasizes the economic and environmental benefits of UV powder coatings compared to traditional systems, indicating a promising future for this technology in various industries.