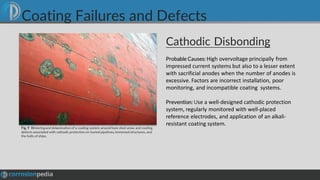

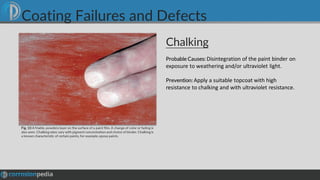

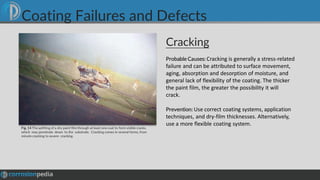

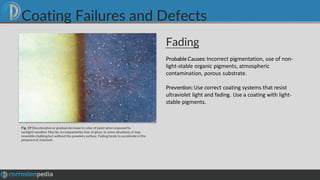

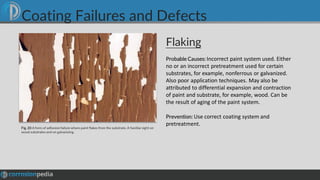

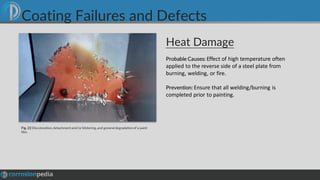

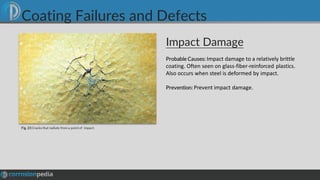

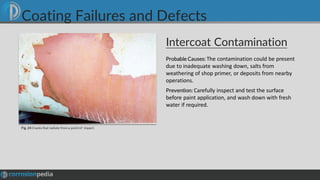

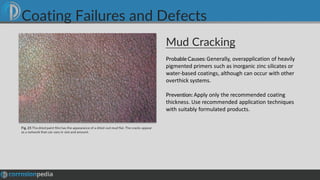

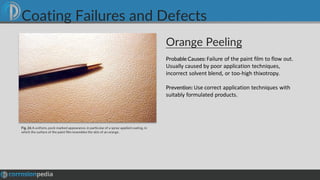

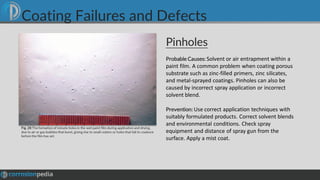

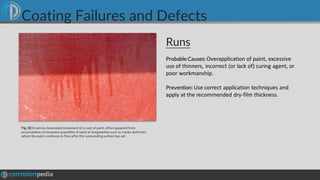

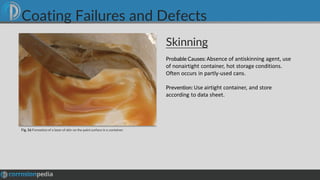

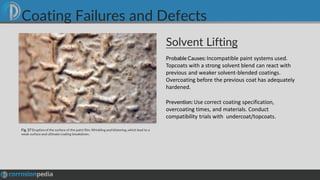

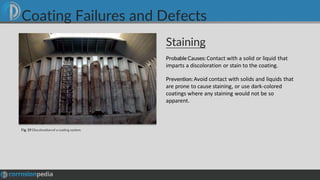

The document is a comprehensive field guide detailing coating failures and defects in protective coatings, authored by experts in the field with extensive experience. It covers various types of defects, probable causes, and preventive measures, highlighting intricate factors that contribute to coating failures throughout their lifecycle. Additionally, it includes photographs and a detailed examination of different defects categorized in illustrated sections based on their characteristics.