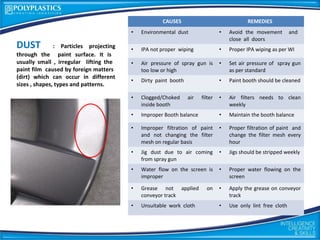

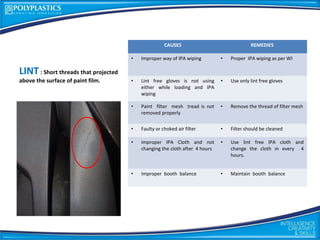

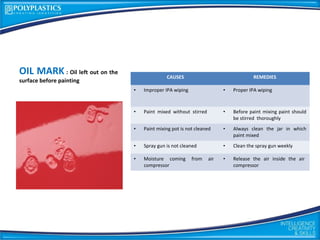

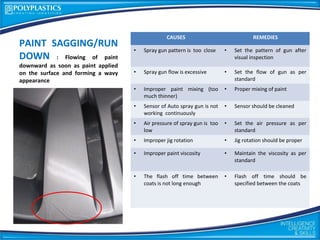

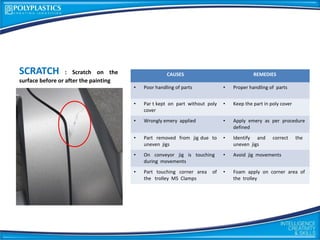

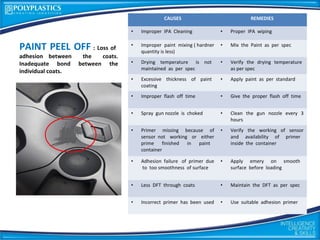

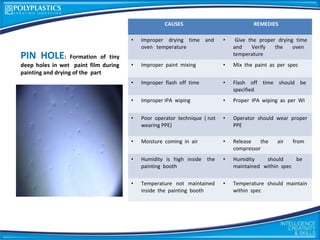

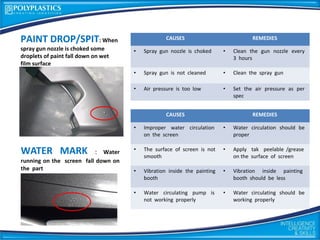

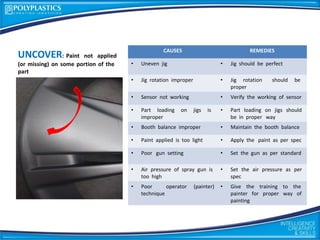

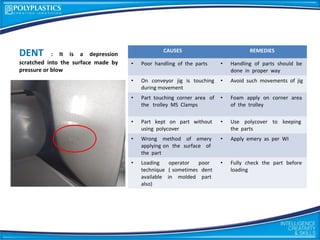

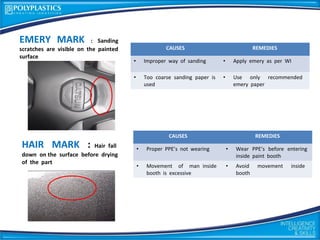

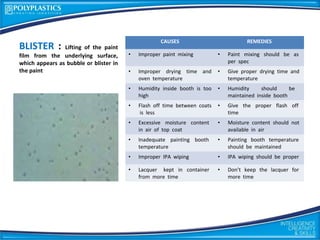

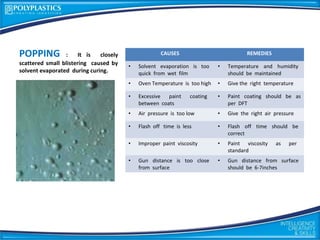

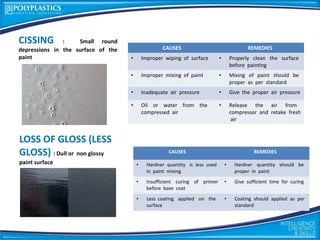

This document provides definitions and causes and remedies for common paint defects seen on automobile parts during the painting process. It defines and describes various defects such as dust, lint, orange peel, oil mark, paint sagging/rundown, scratch, paint peel off, pin hole, paint drop/spit, water mark, uncover, dent, emery mark, hair mark, blister, popping, and cissing. For each defect, it lists potential causes and recommended remedies to address the issue and prevent reoccurrence. The document serves as a reference for identifying and troubleshooting common paint defects.