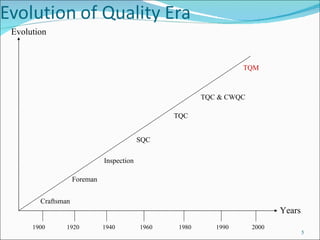

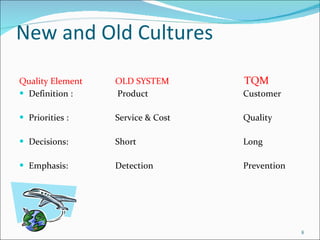

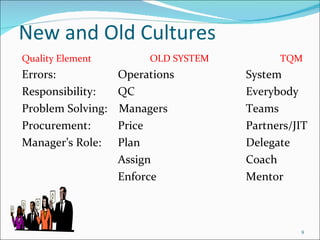

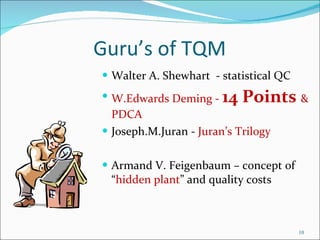

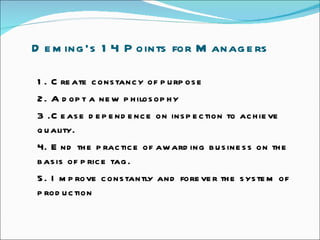

The document discusses Total Quality Management (TQM), defining it as a management strategy aimed at embedding quality awareness in all organizational processes. It explains that TQM requires maintaining high quality standards across all business operations by doing things right the first time and eliminating defects and waste. The document outlines the basic approaches of TQM, including committed management support, customer focus, workforce involvement, and continuous process improvement. It also discusses some key figures in TQM development like Deming and his 14 Points for managers.