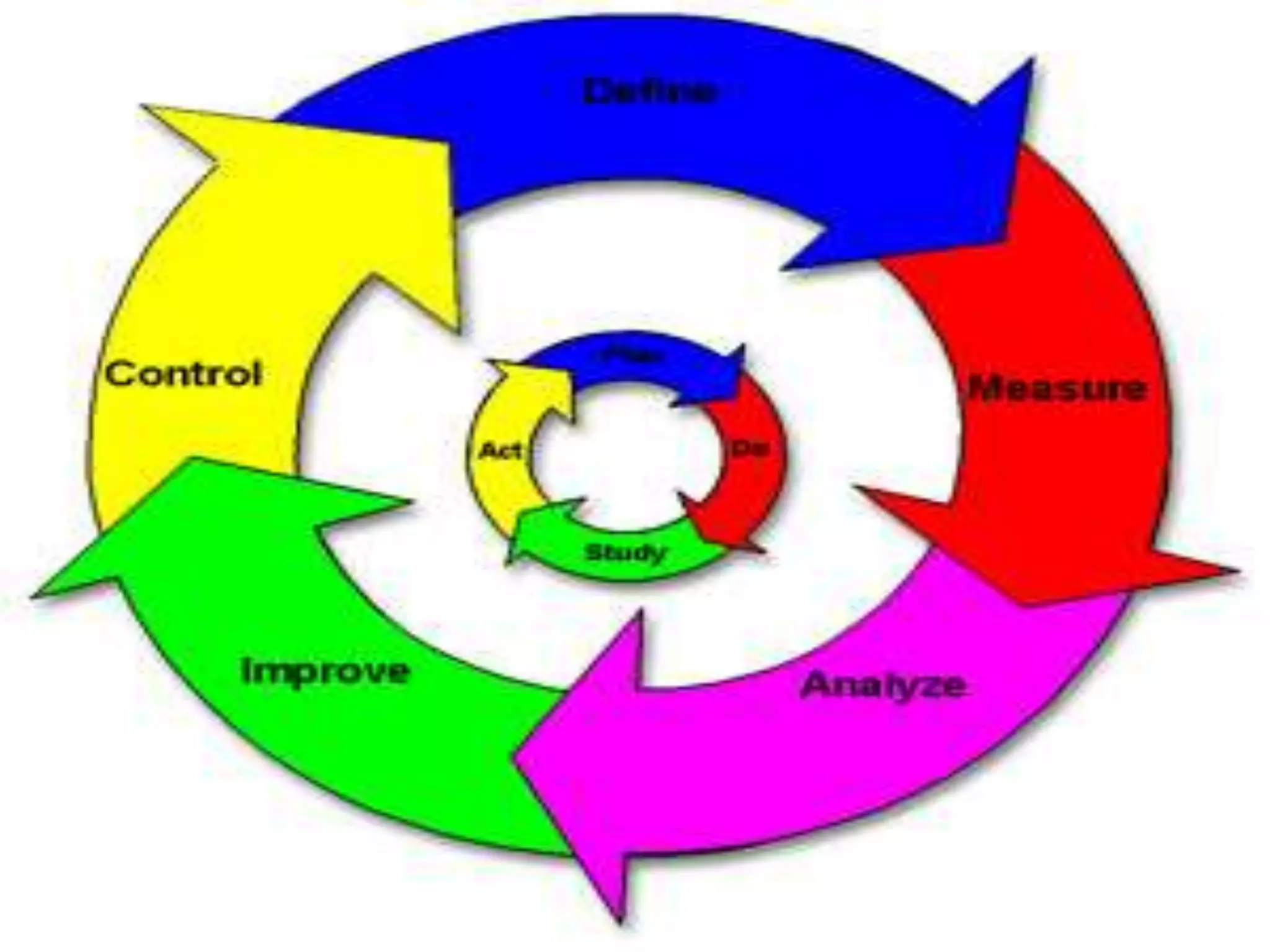

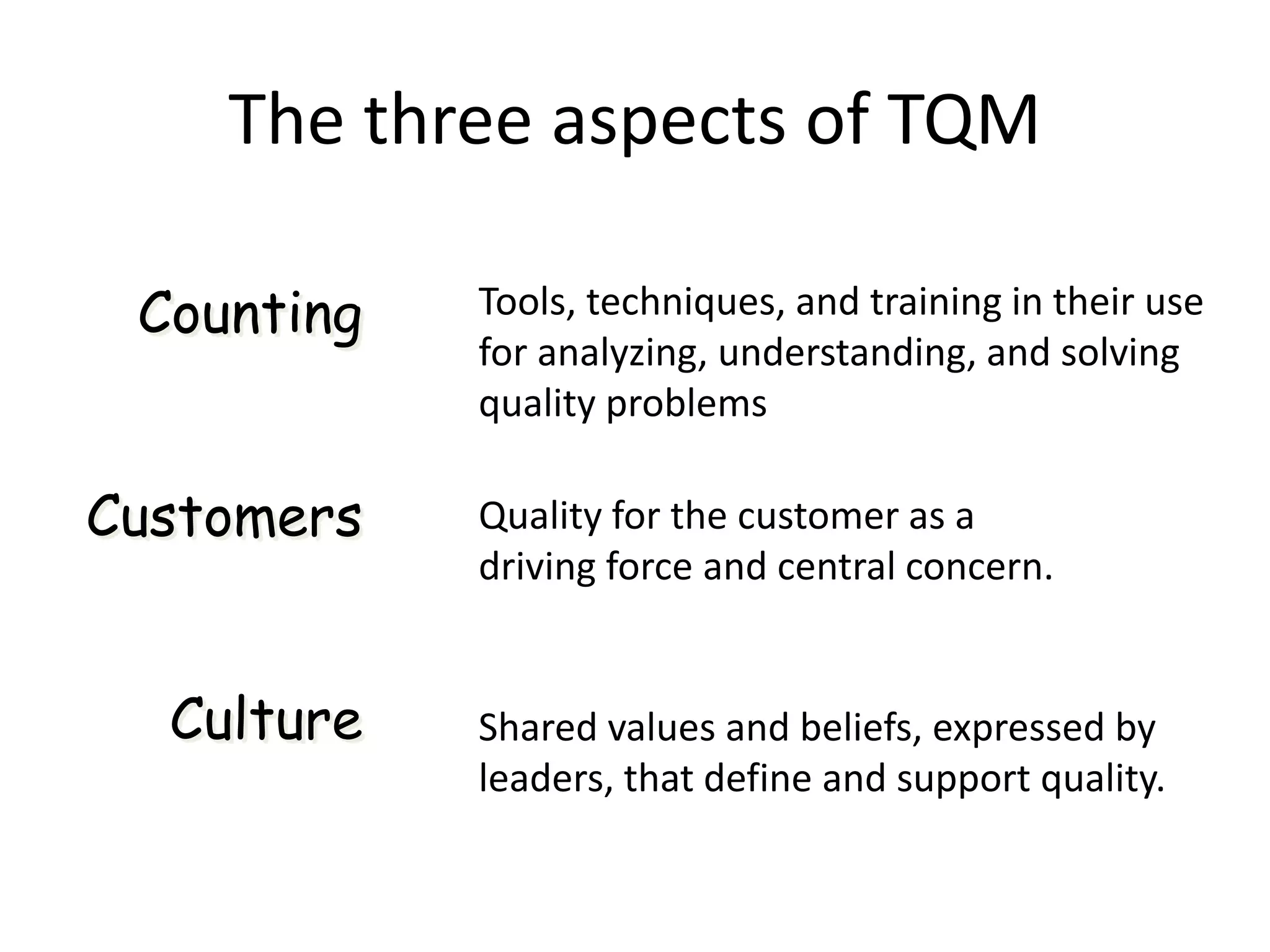

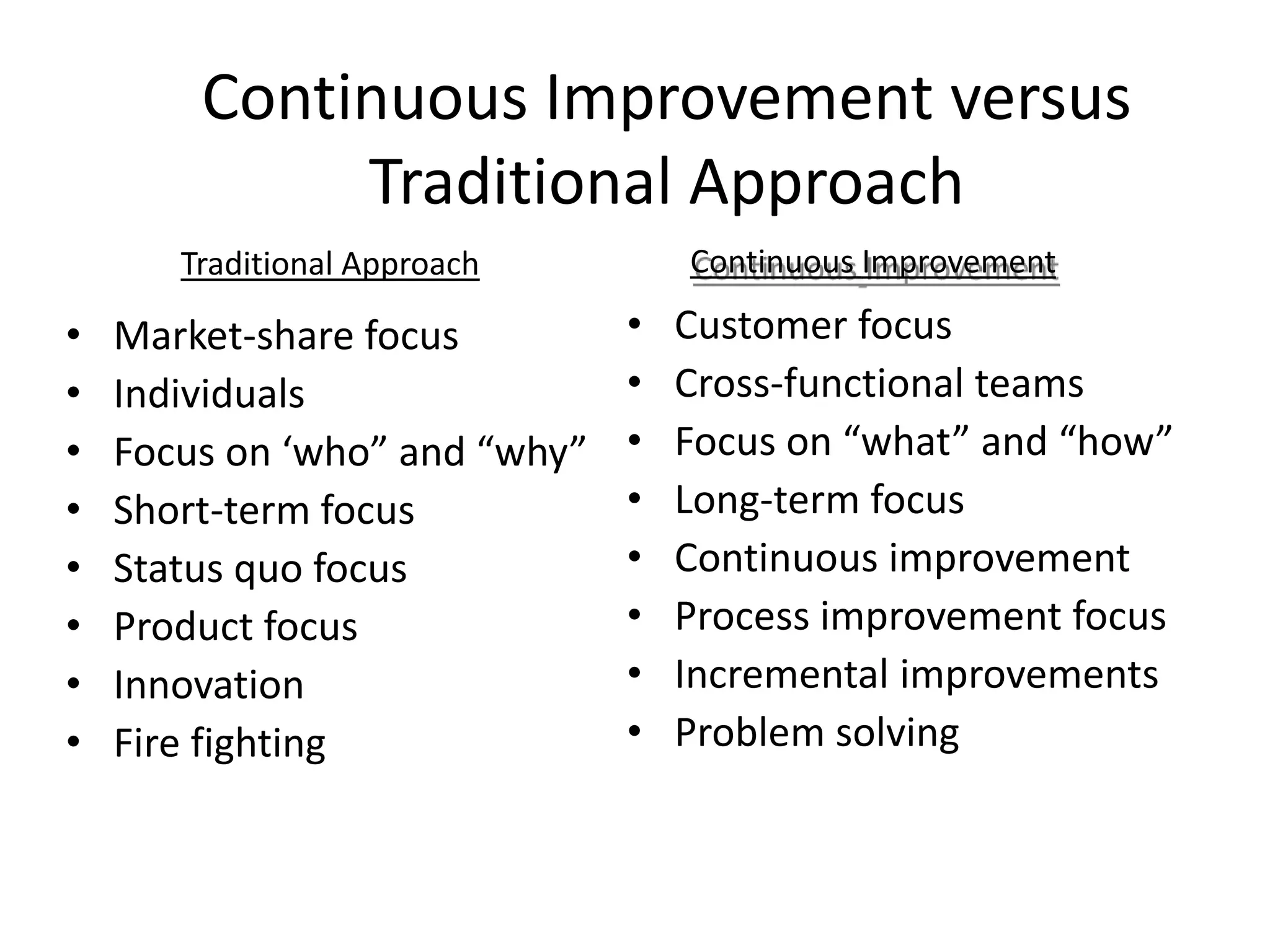

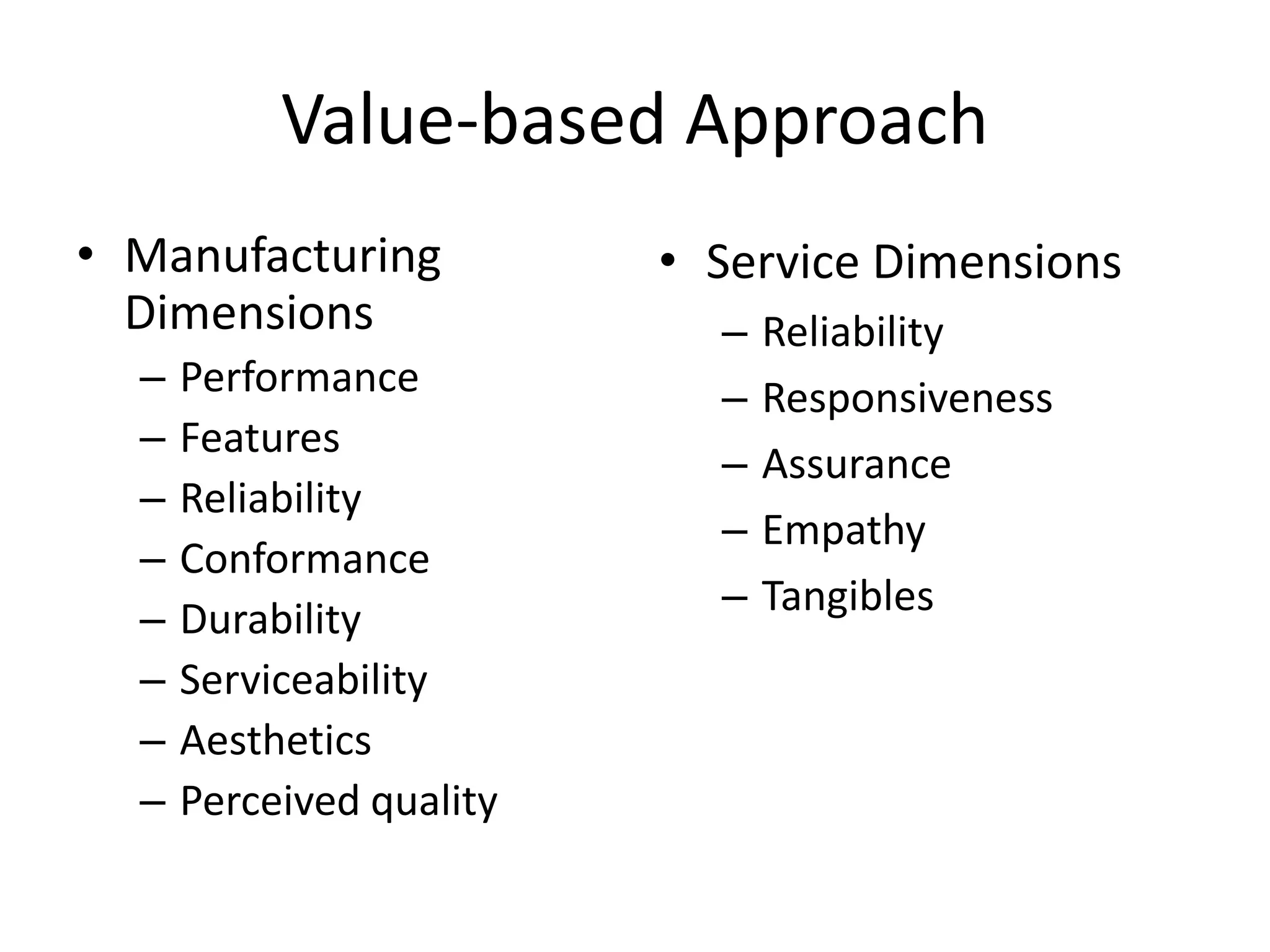

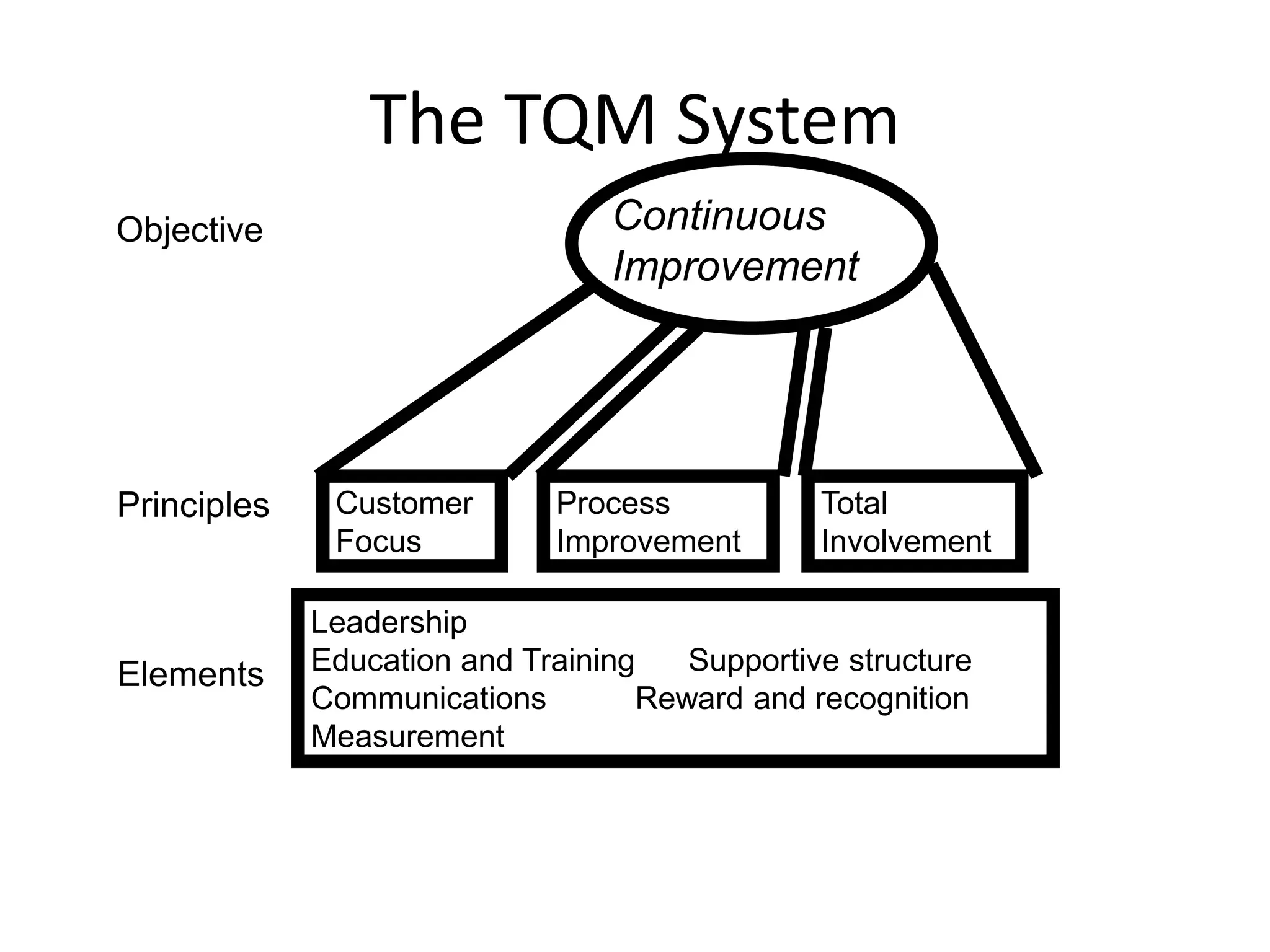

Total Quality Management (TQM) aims to manage the whole organization to achieve excellence by focusing on customer satisfaction. TQM requires commitment from top management and the involvement of the entire workforce to continuously improve processes, products and services. It emphasizes preventing poor quality, meeting customer requirements, and aiming for continuous improvements.