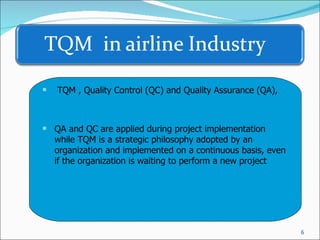

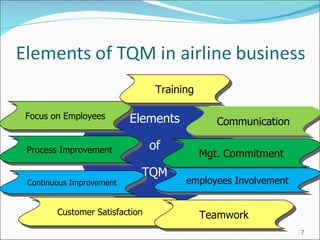

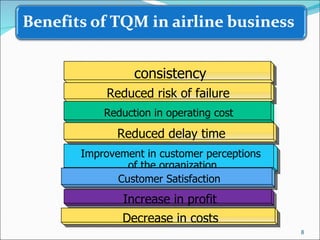

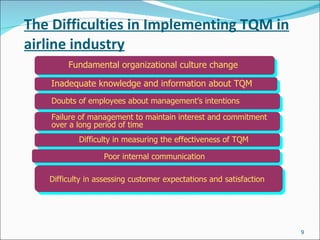

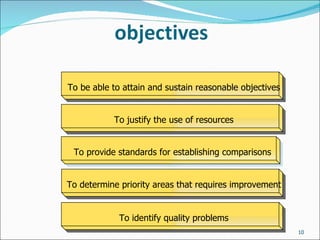

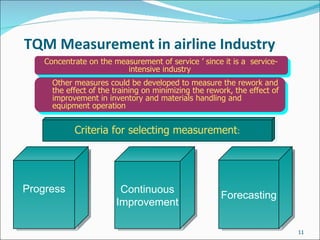

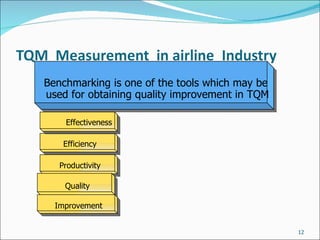

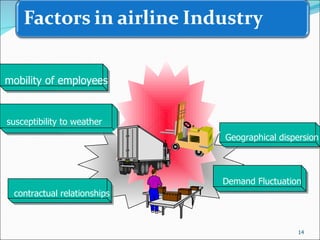

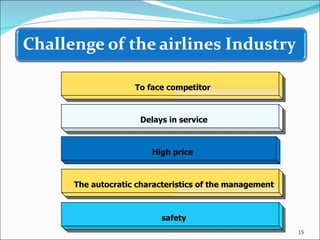

The document discusses total quality management (TQM) in the airline industry. TQM aims to achieve customer satisfaction and cost effectiveness through process improvement, customer and employee involvement, and training. Key elements of TQM for airlines include continuous improvement, communication, customer satisfaction, management commitment, teamwork, and process improvement. Implementing TQM in airlines can be difficult due to issues like organizational culture change and measuring effectiveness, but benefits include reduced costs, risks, delays, and improved customer perceptions.