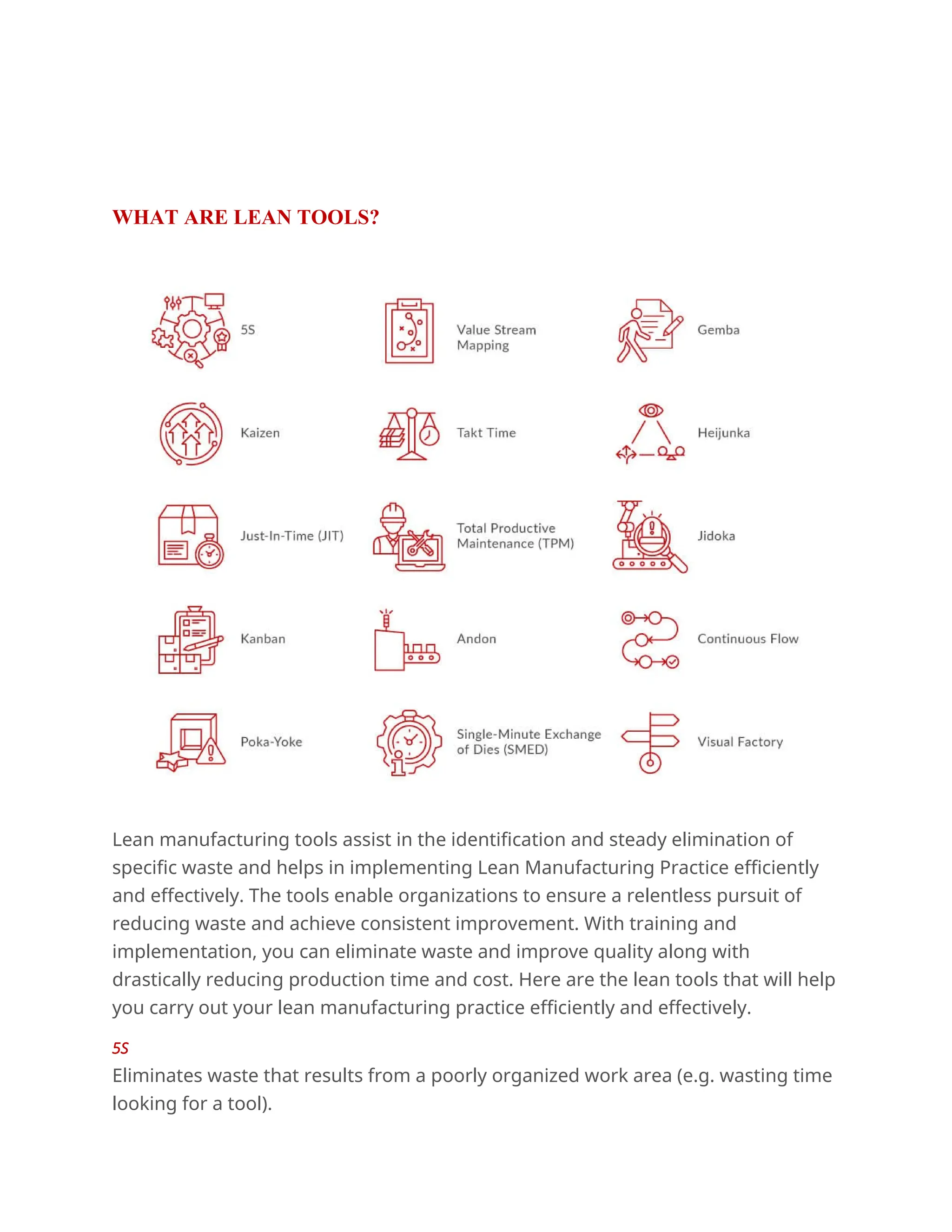

Lean tools facilitate lean manufacturing by aiming to create customer value through the reduction of non-value added activities, ultimately minimizing waste and optimizing production processes. Key principles of lean include specifying product value, eliminating waste types (muri, mura, muda), and employing tools like 5S, Kaizen, and Just-in-Time to enhance efficiency. Organizations practicing lean focus on continuous improvement, error prevention, and maintaining a clear understanding of workflows to achieve operational excellence.