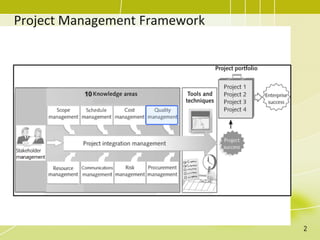

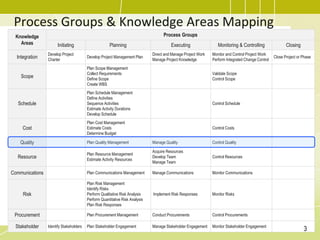

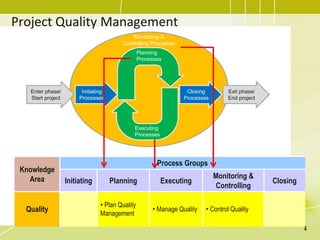

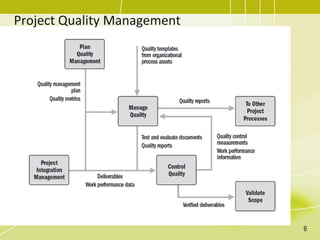

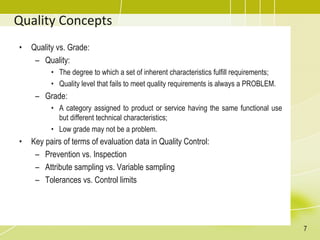

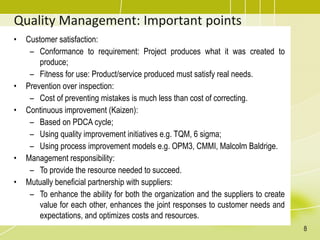

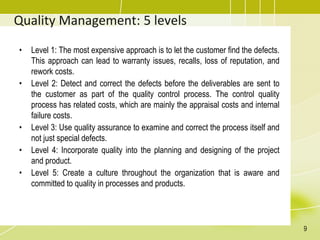

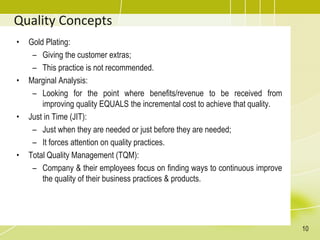

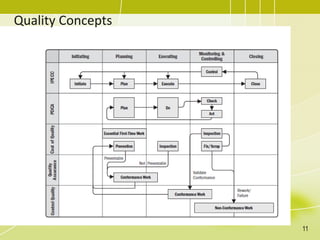

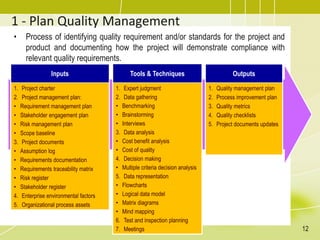

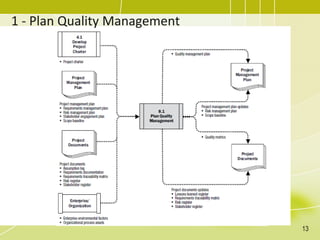

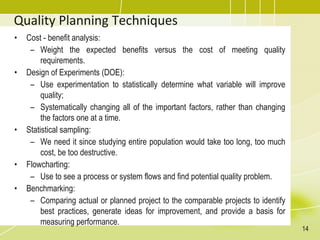

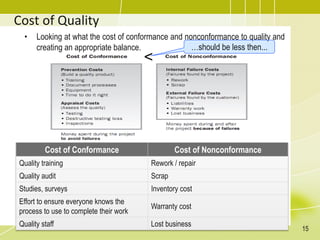

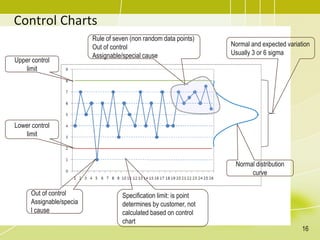

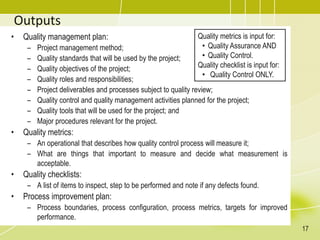

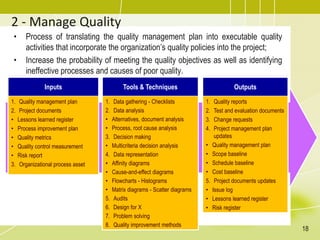

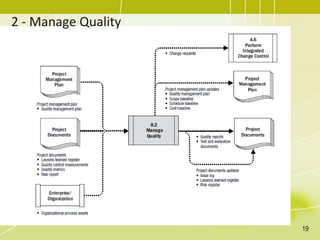

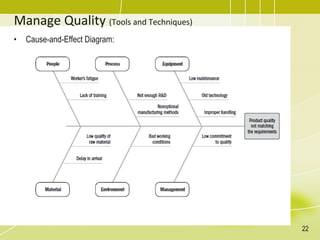

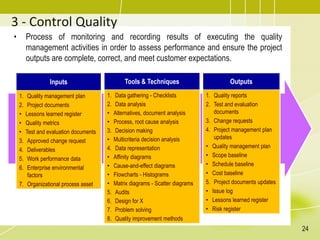

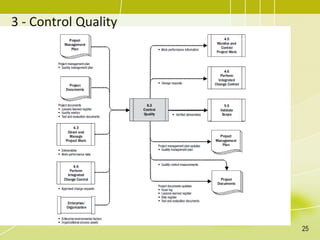

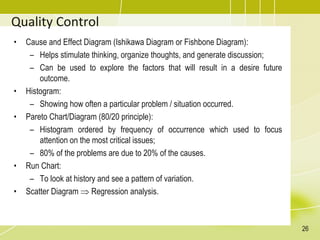

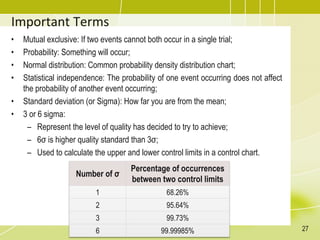

The document discusses project quality management. It provides an overview of quality concepts, quality planning techniques, and the three processes involved in quality management: plan quality management, manage quality, and control quality. Key points include defining quality and quality levels, using tools like cost-benefit analysis and control charts for quality planning, and techniques like audits, problem solving and process analysis that are used to manage and control quality during project execution.