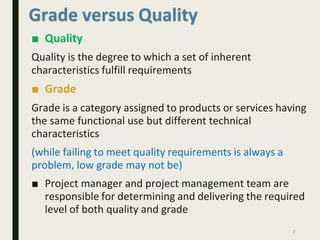

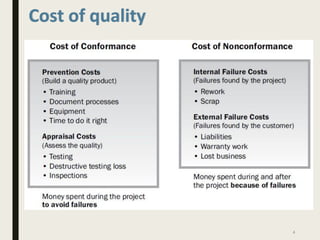

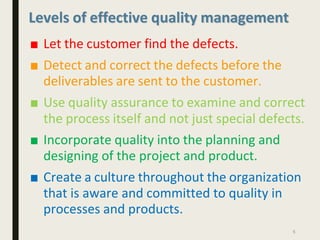

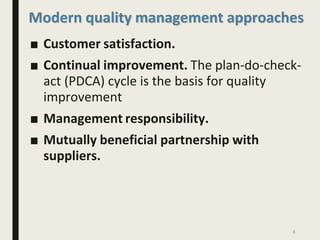

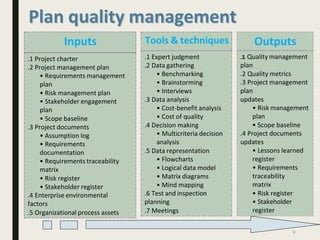

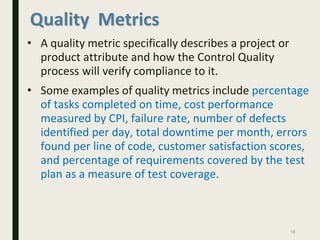

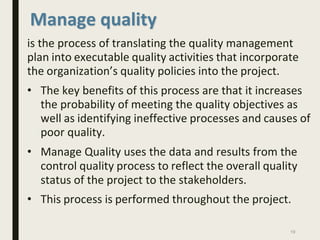

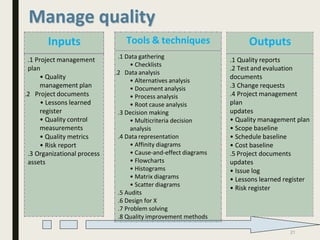

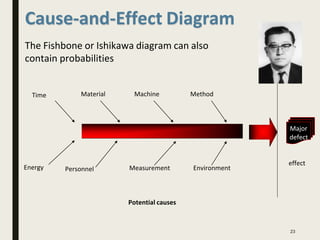

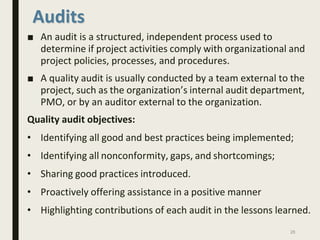

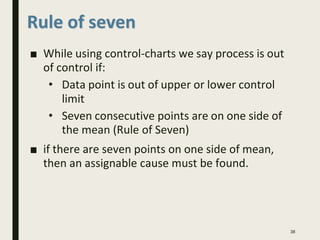

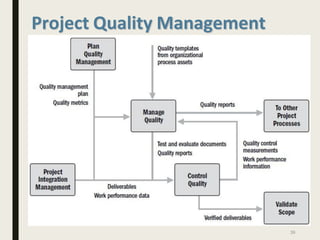

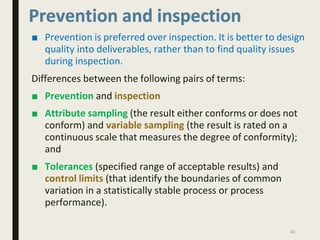

The document outlines the principles of project quality management, emphasizing the distinction between quality and grade, and the responsibilities of project managers in achieving both. It describes the steps involved in quality planning, management, and control, including the importance of setting quality standards, monitoring performance, and conducting audits. Additionally, it highlights modern quality management approaches like customer satisfaction and continual improvement methodologies such as the PDCA cycle.