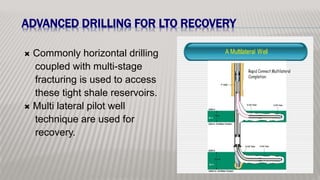

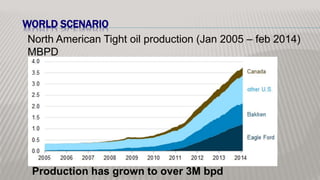

Tight oil, also called light tight oil, refers to oil trapped in low-porosity shale or siltstone formations located deep underground. Horizontal drilling and hydraulic fracturing are used to extract the tightly locked oil. These formations have very low permeability and porosity and require advanced drilling techniques. North American tight oil production has grown significantly since 2005 using these methods, contributing to reduced oil imports. Future global production from shale is estimated to remain high through 2050 as more regions develop their shale resources.