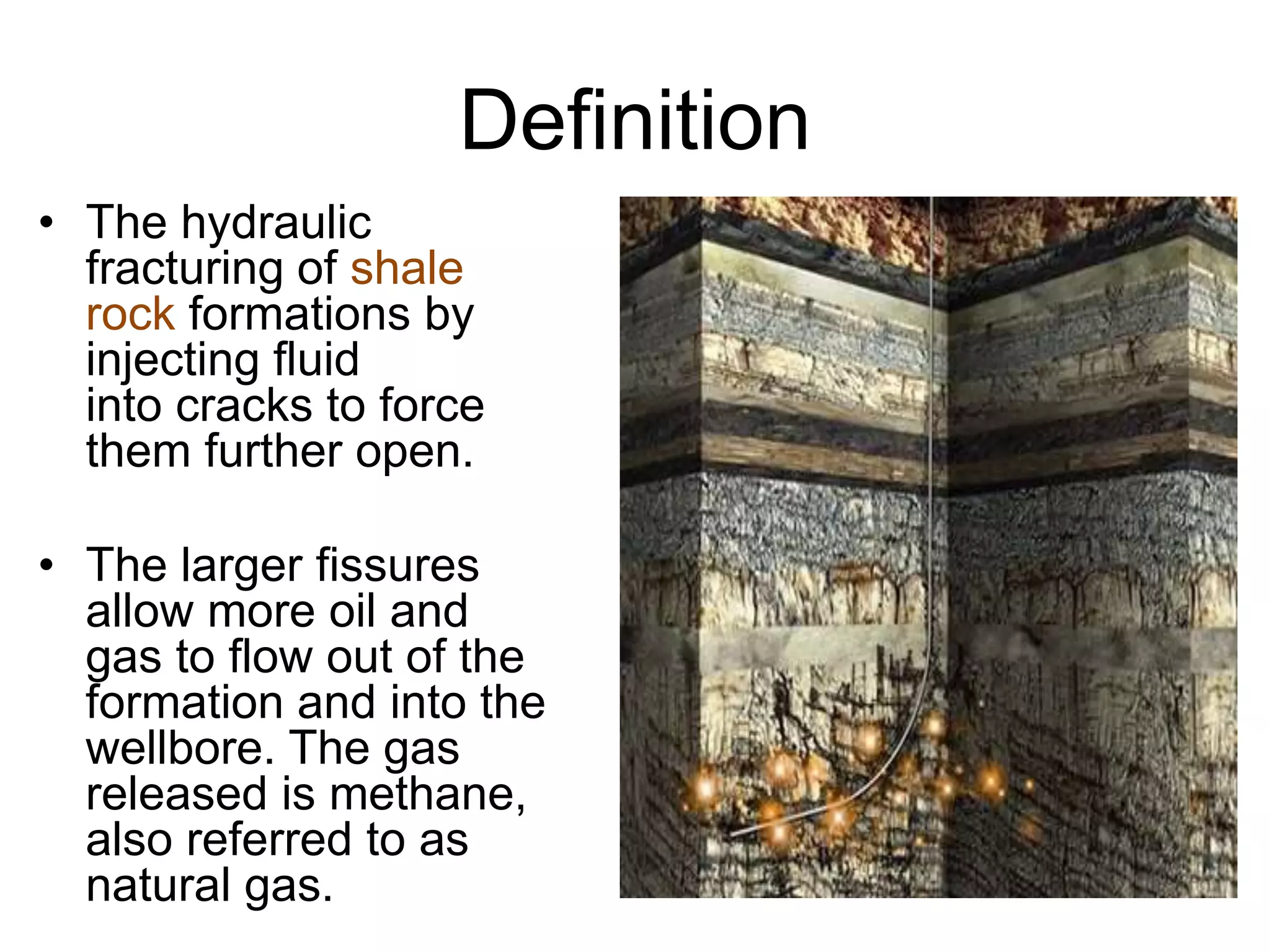

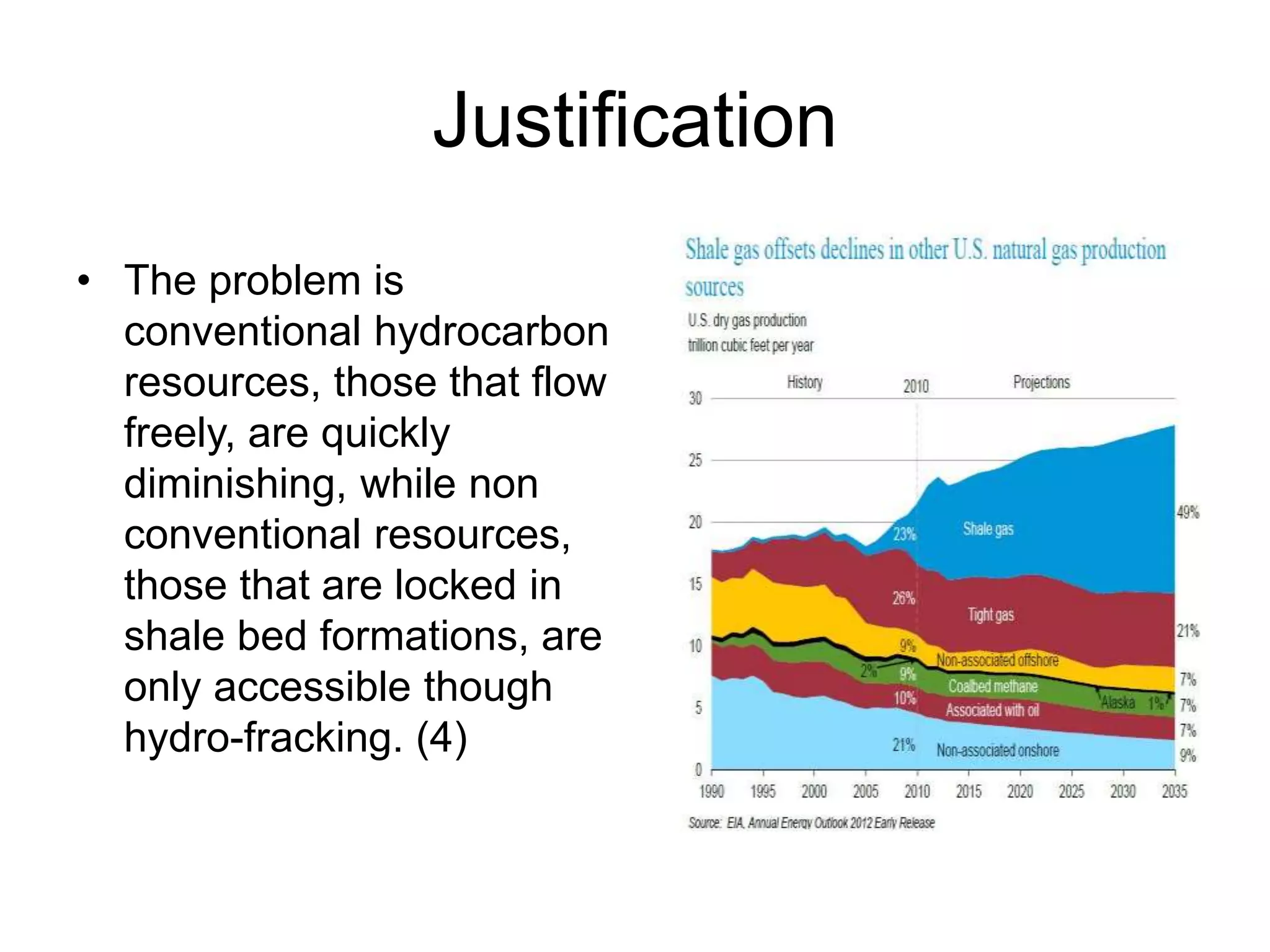

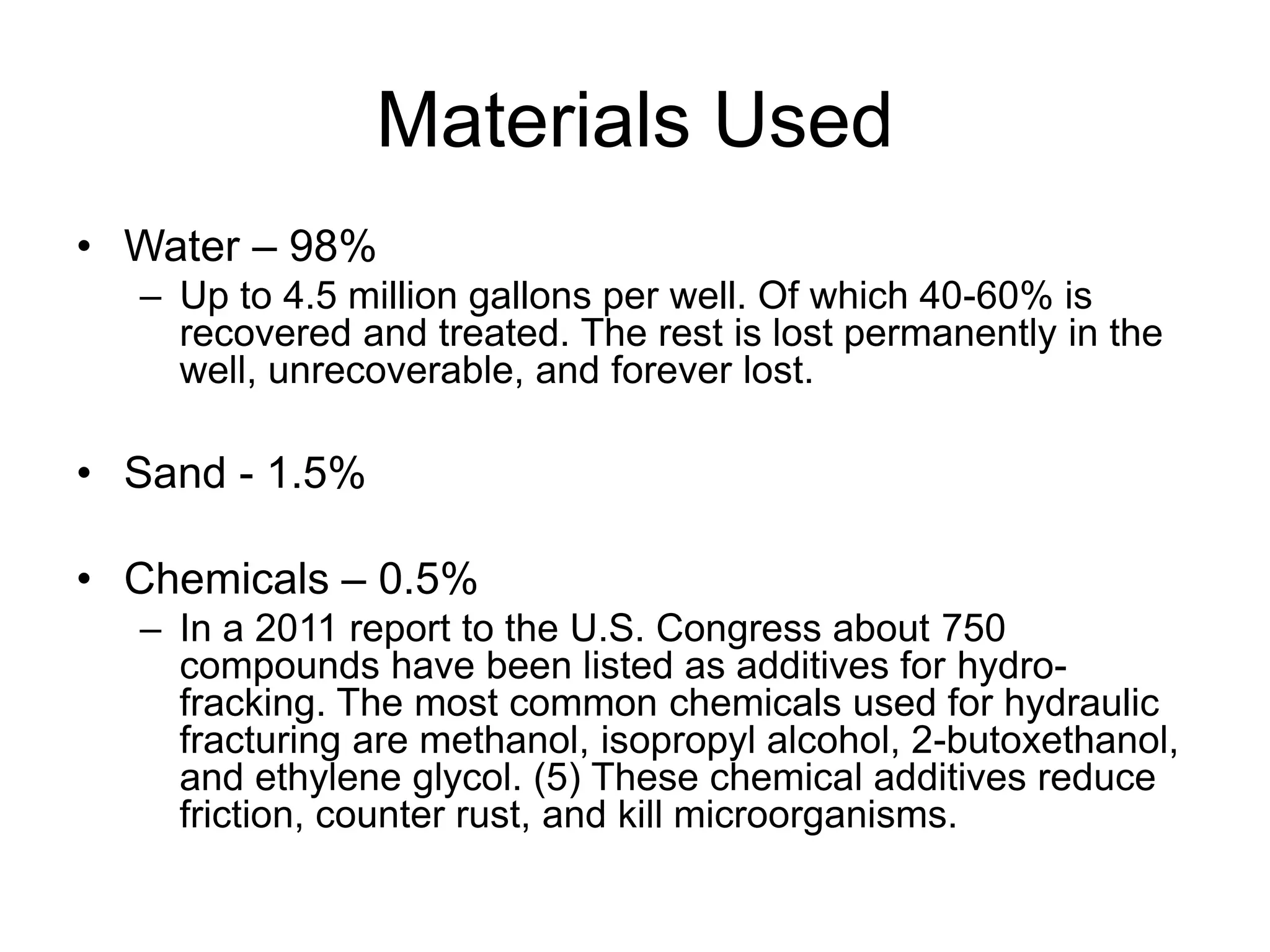

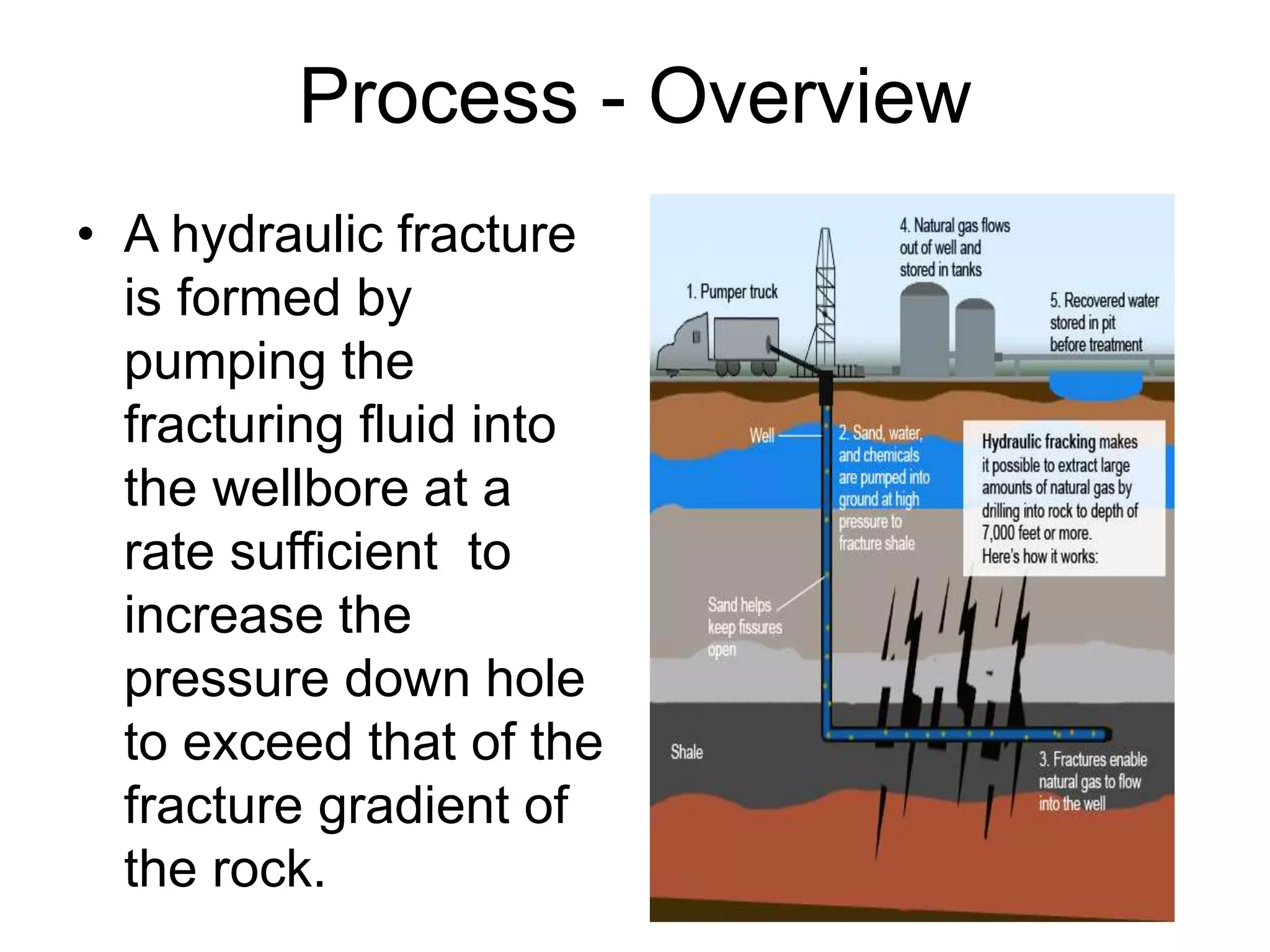

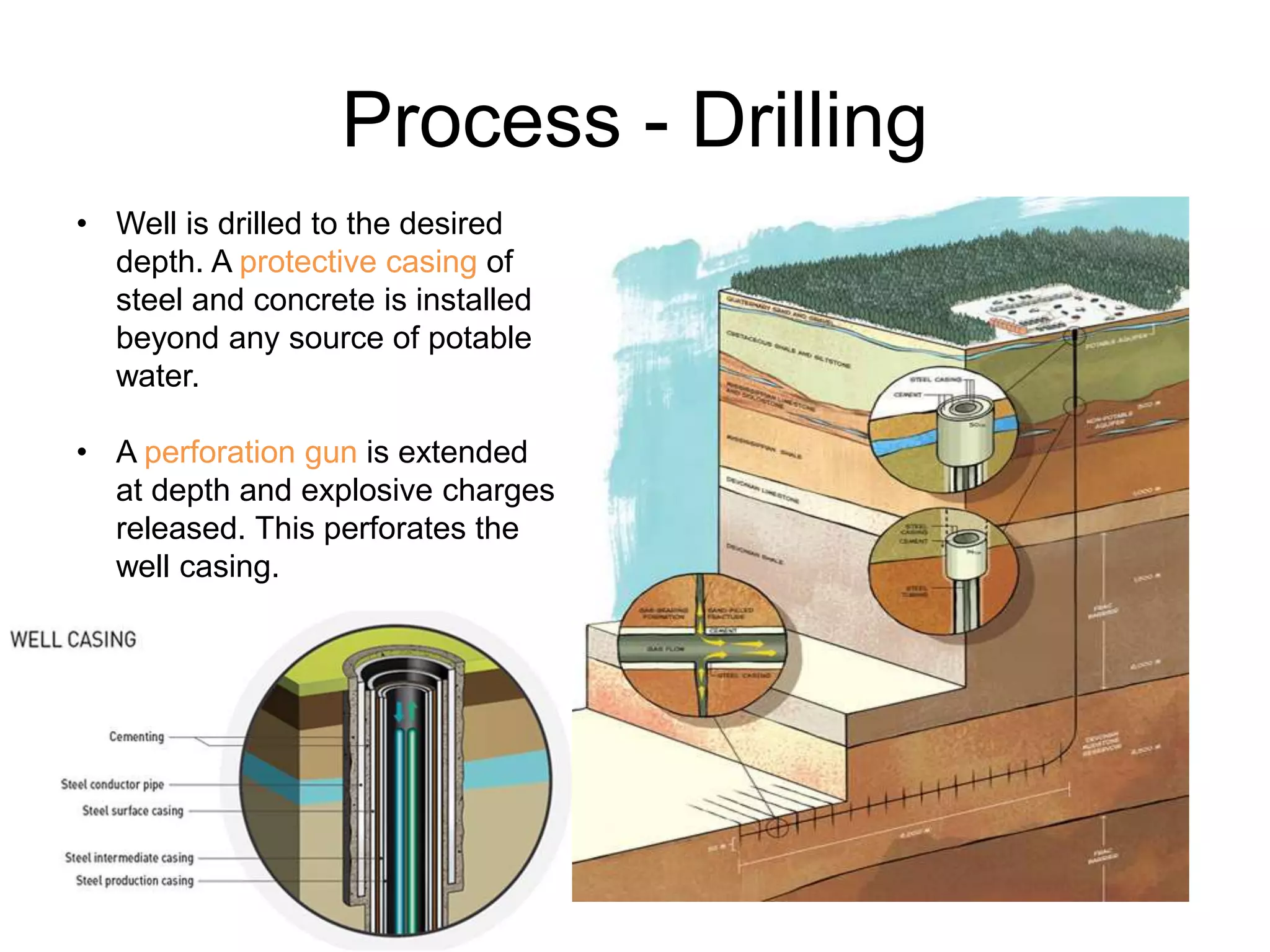

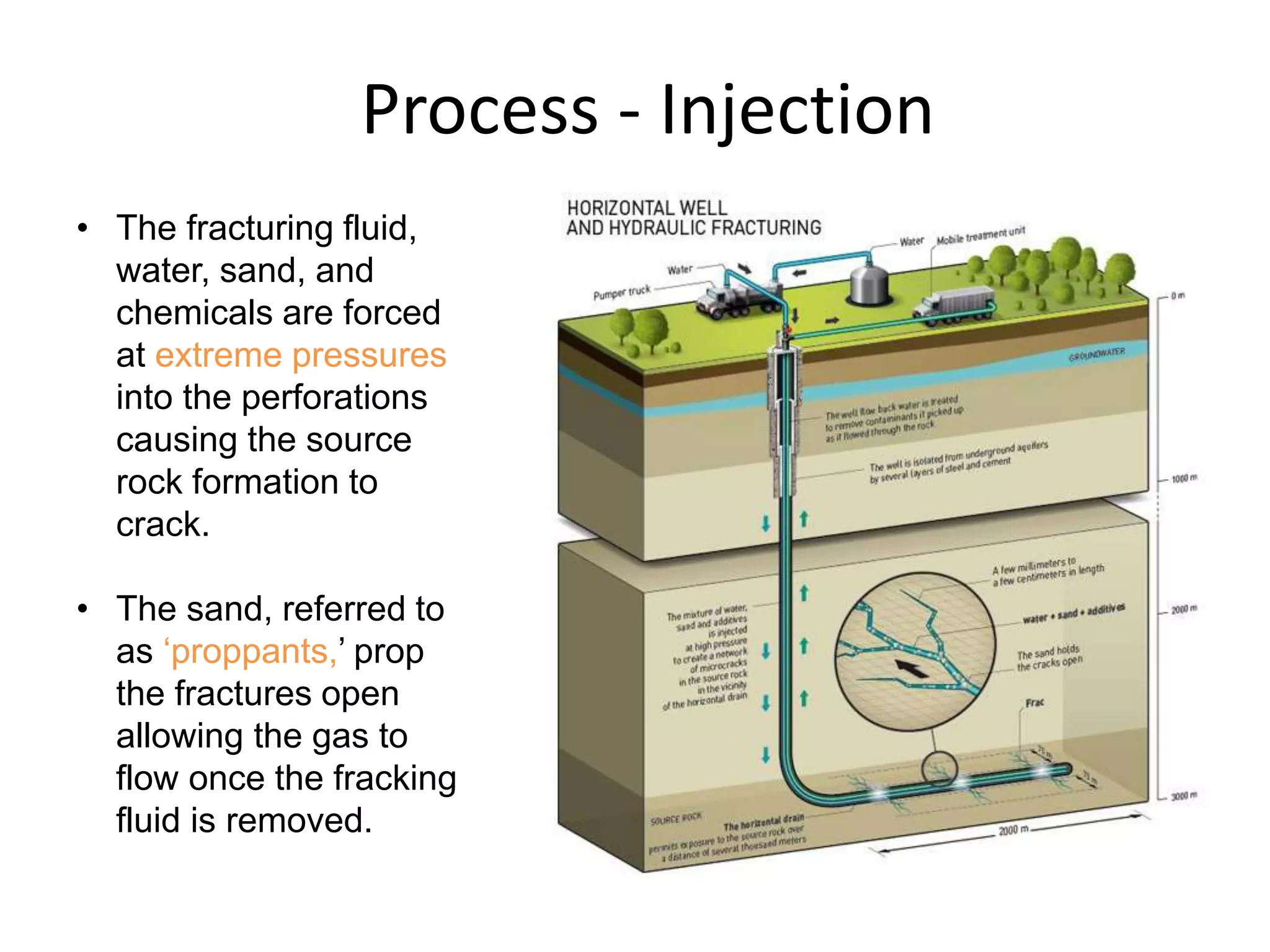

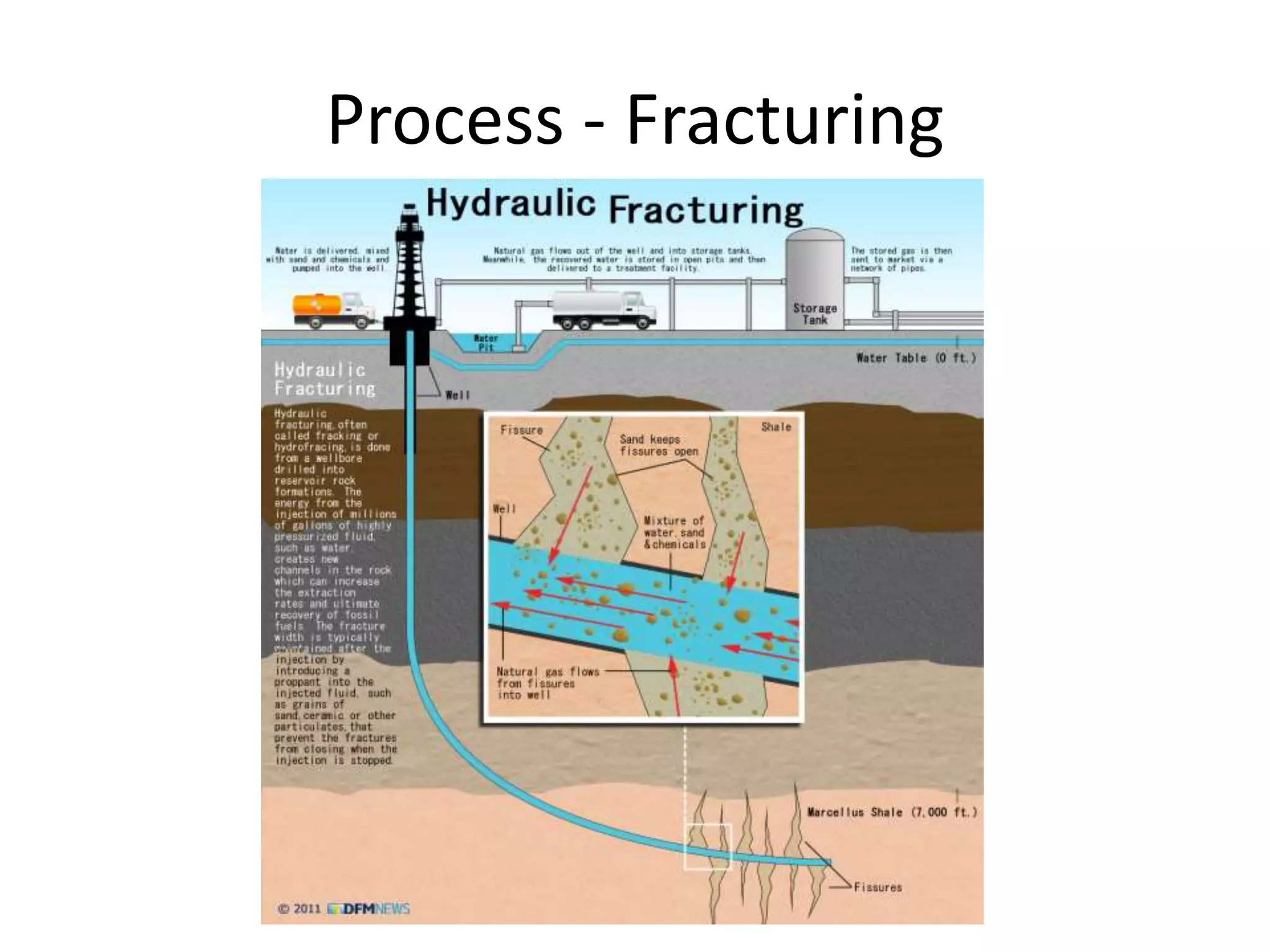

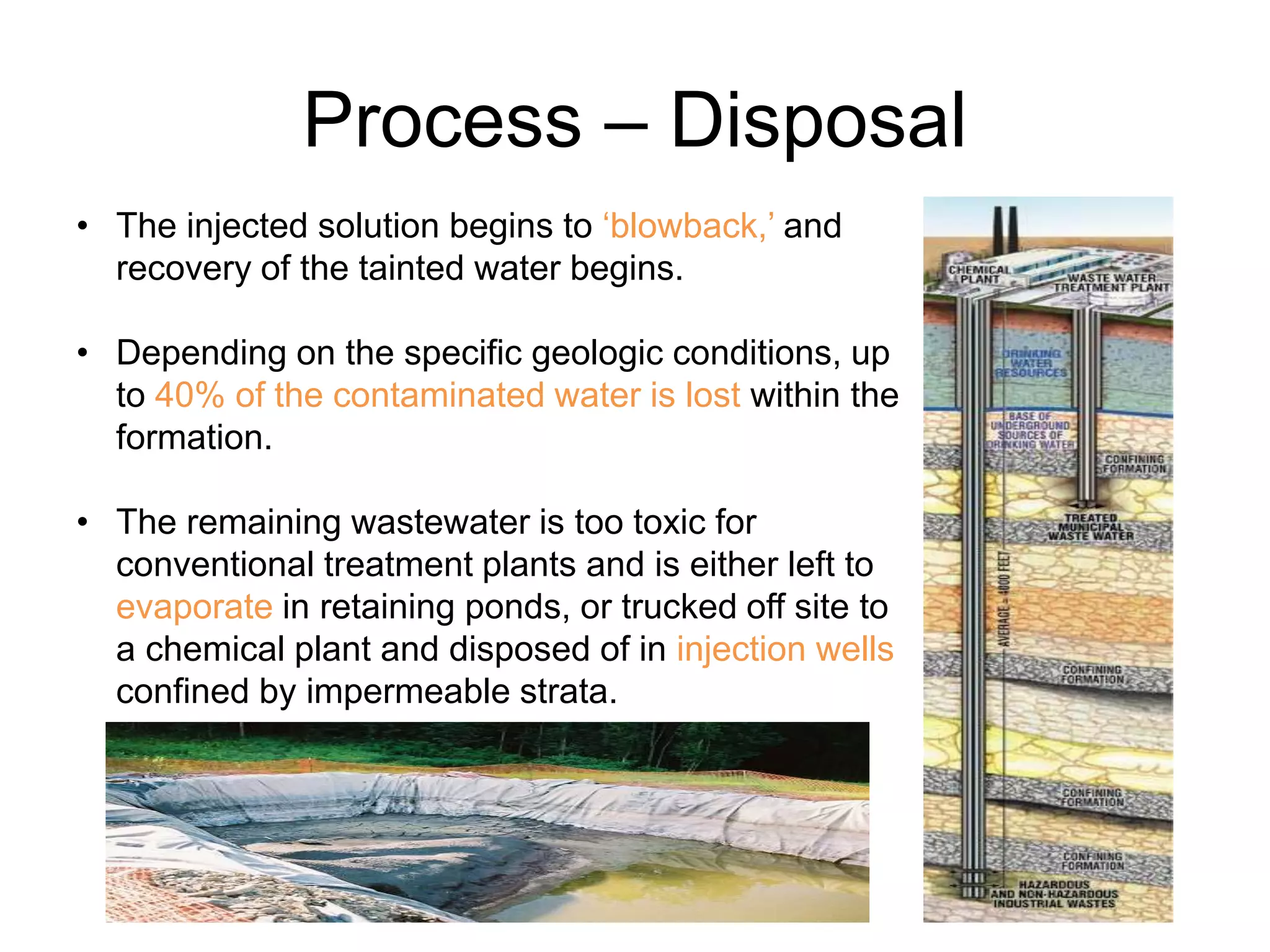

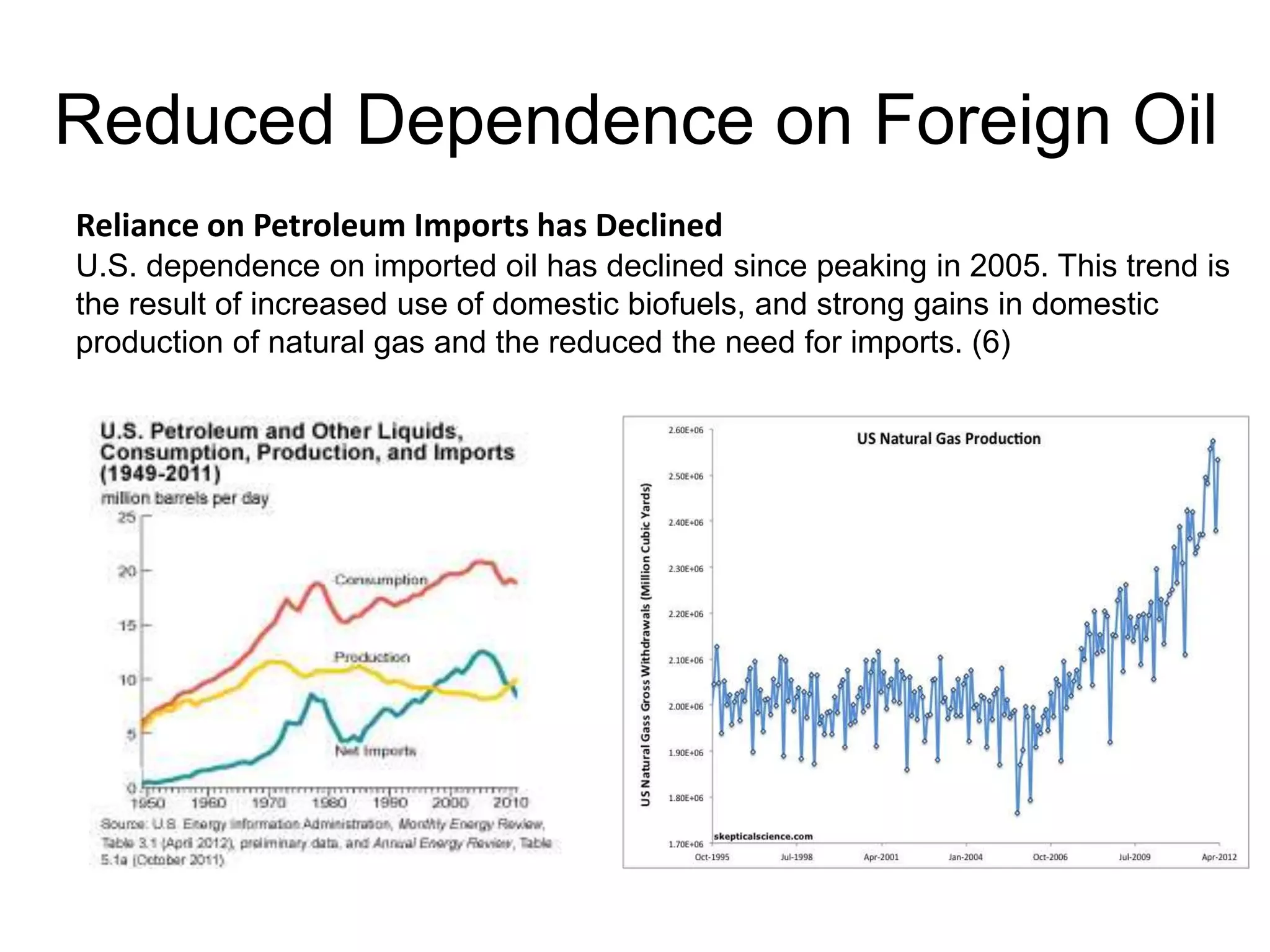

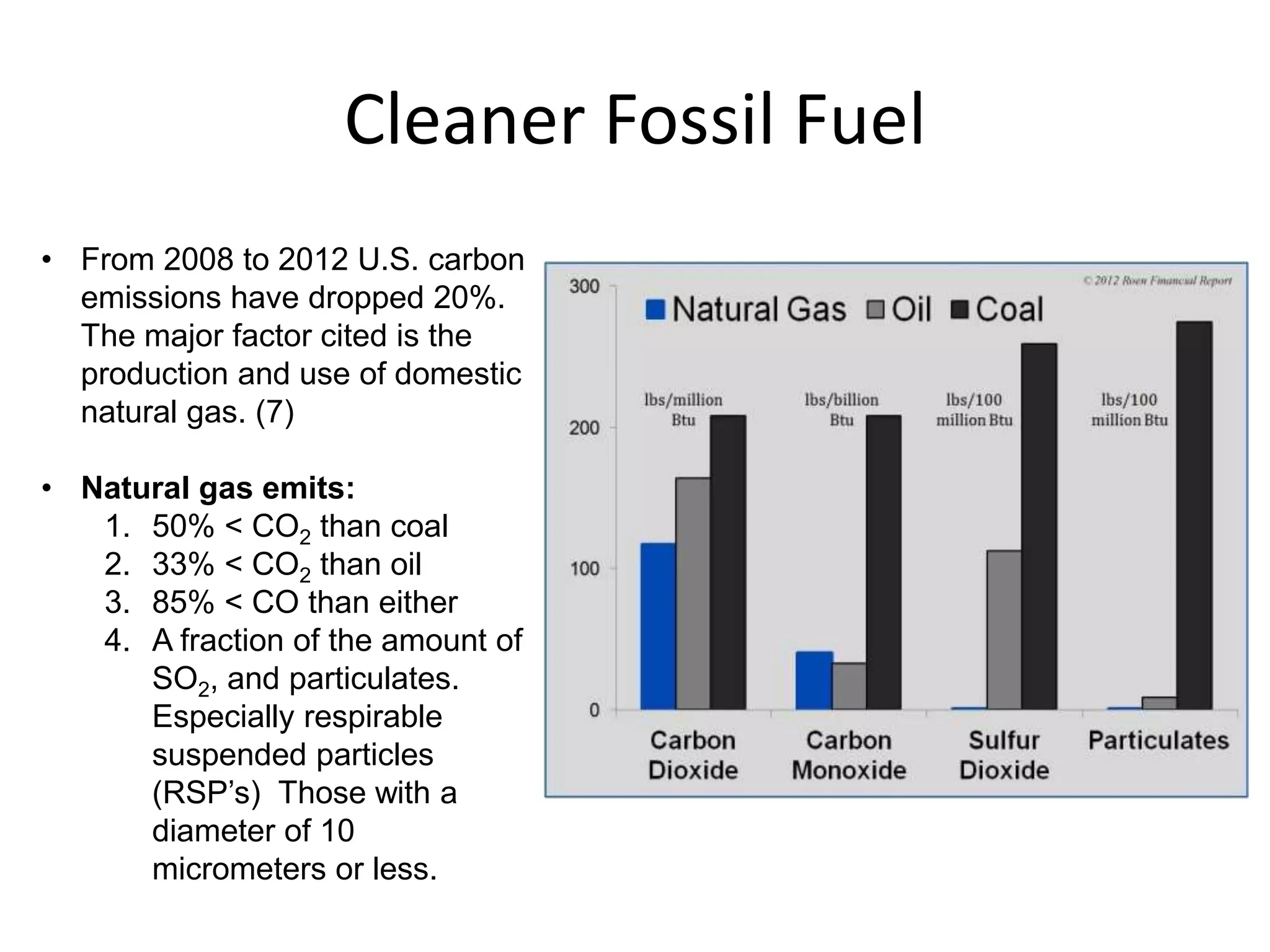

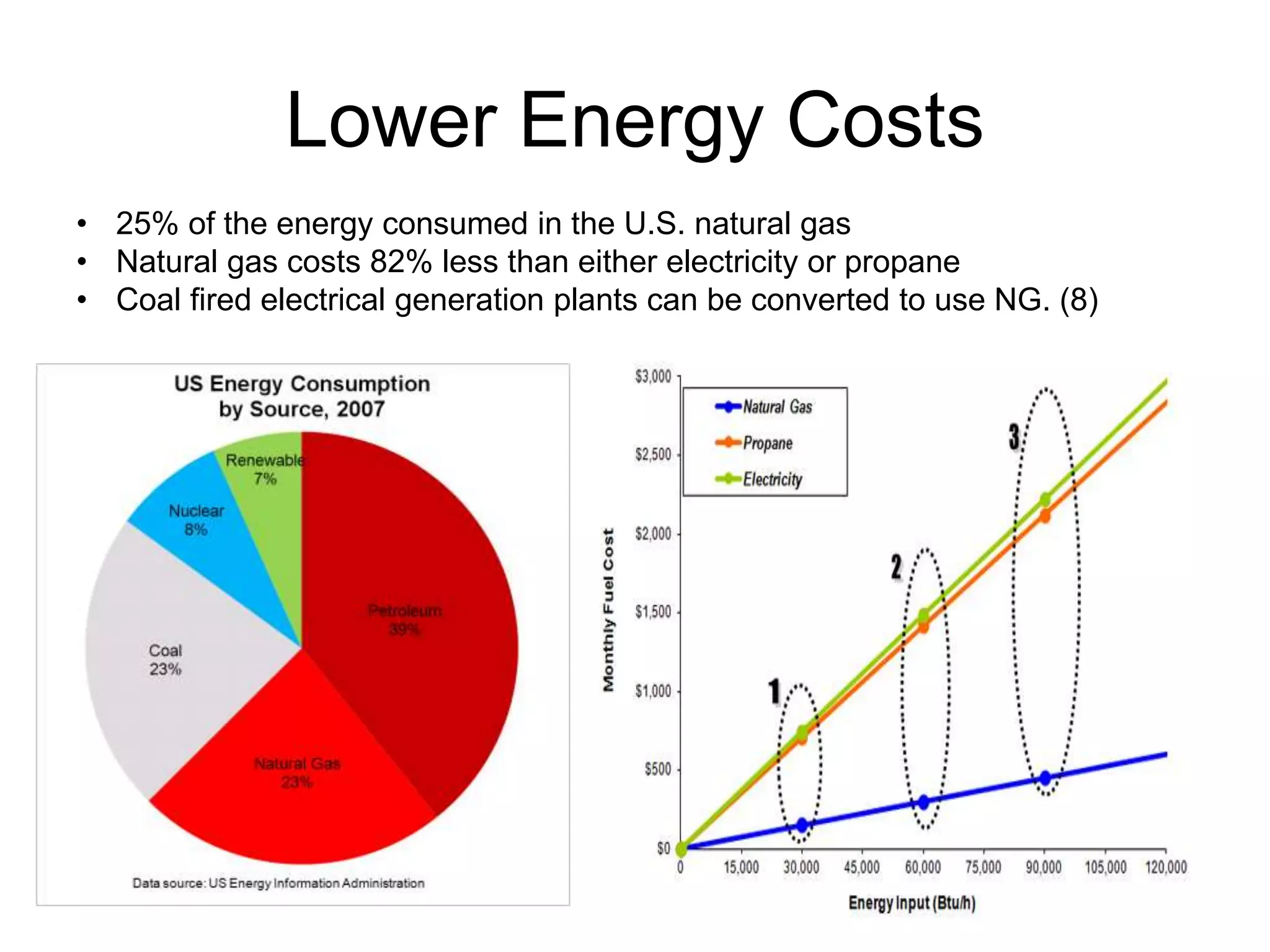

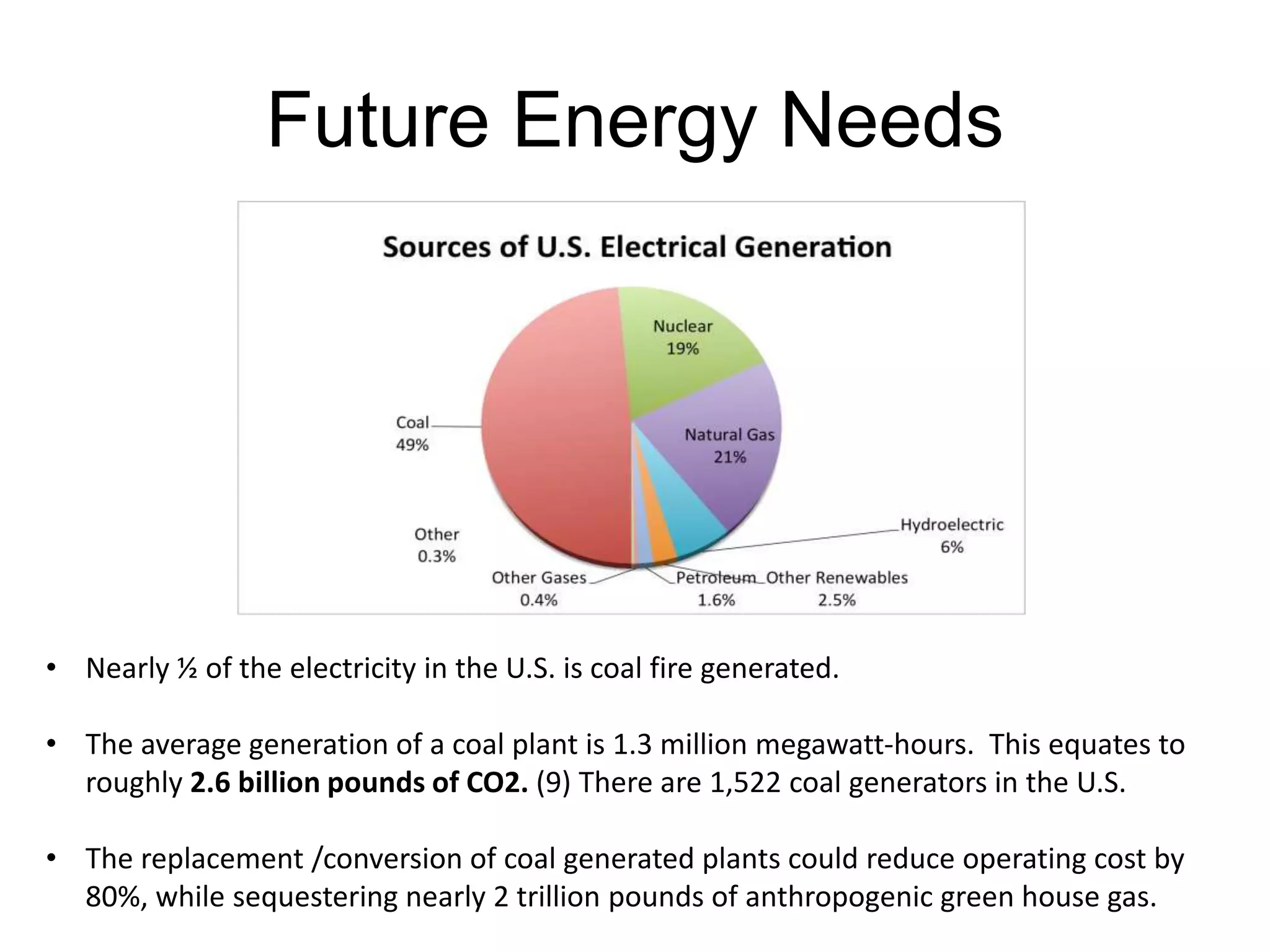

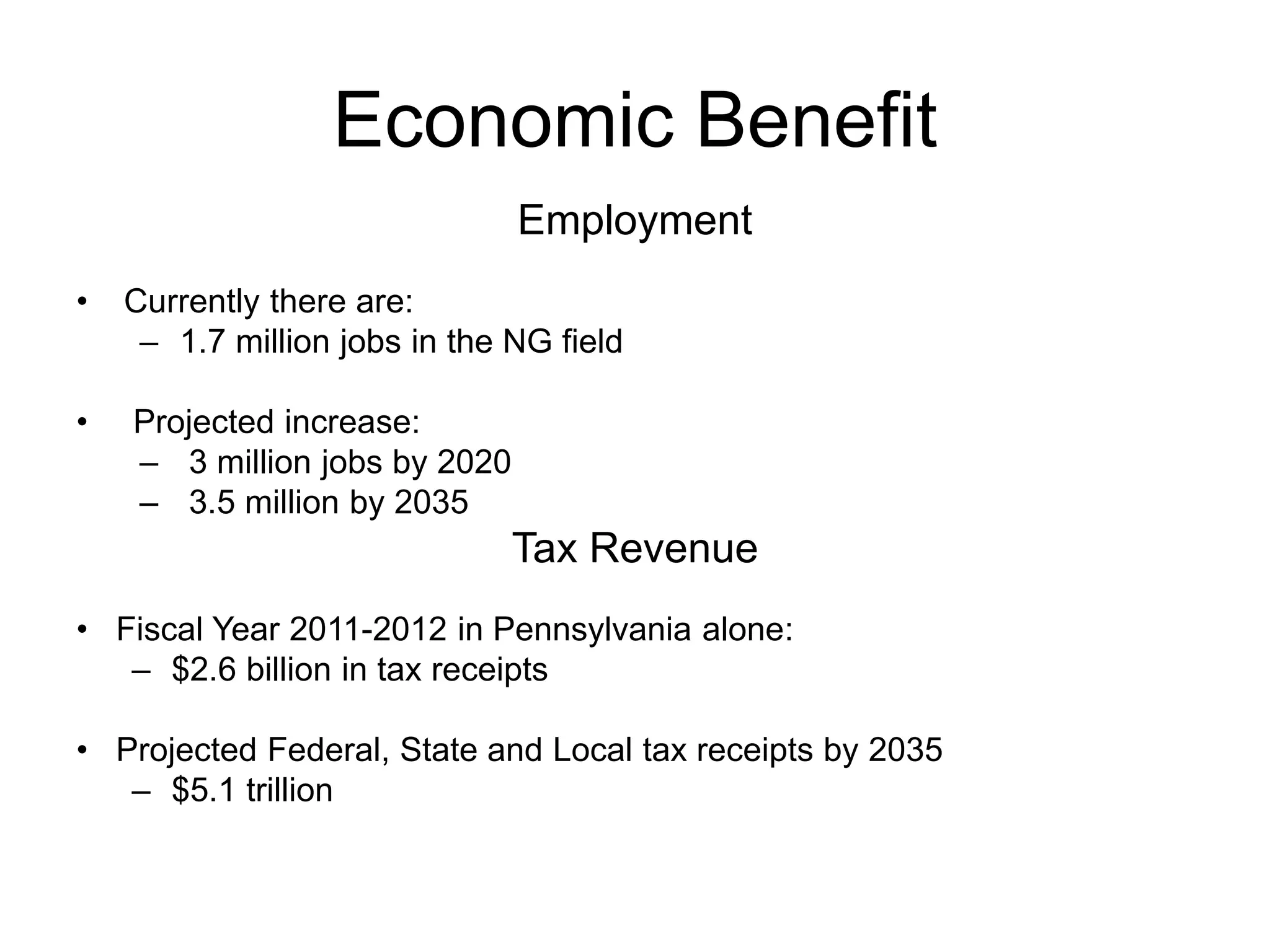

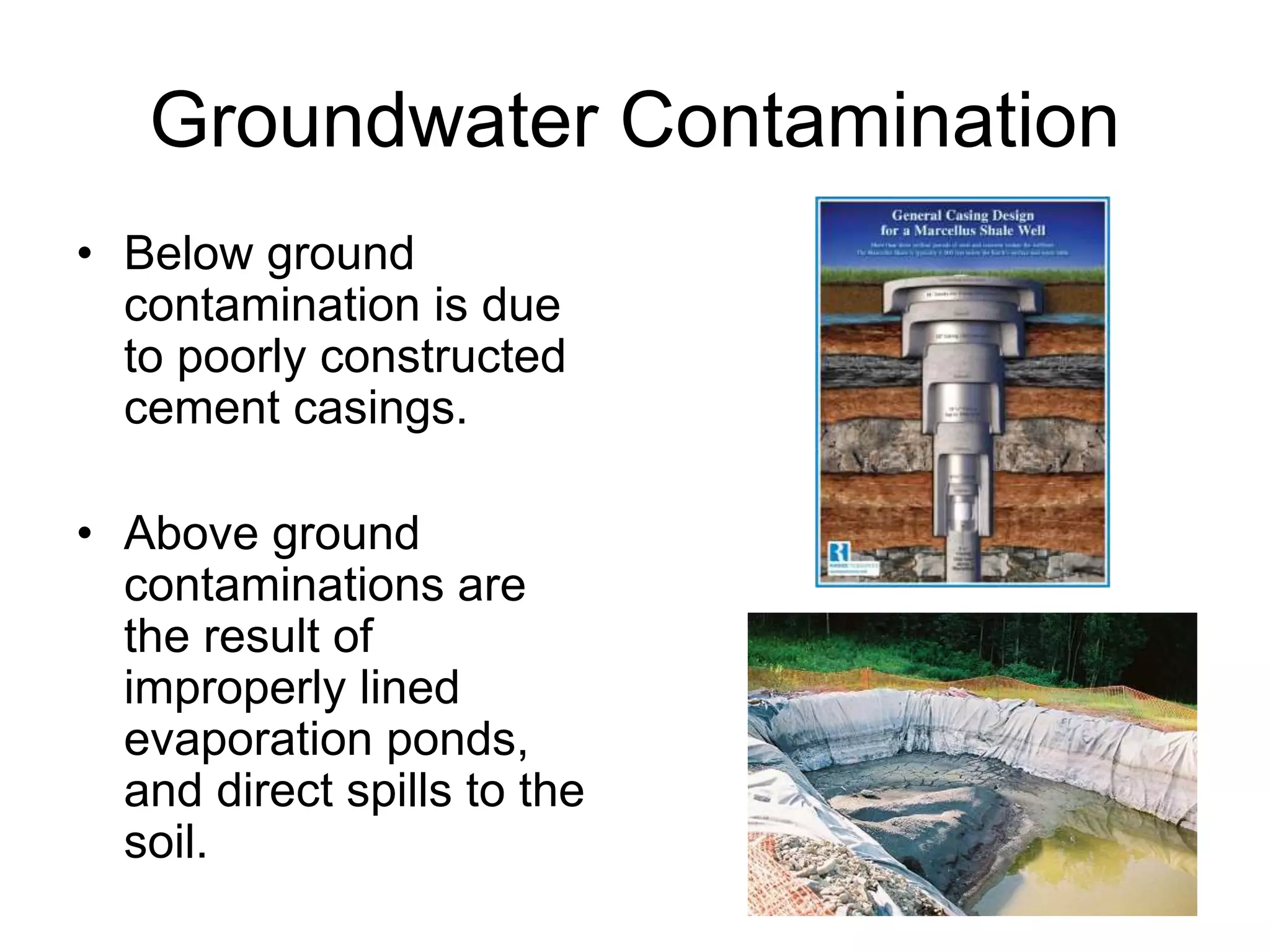

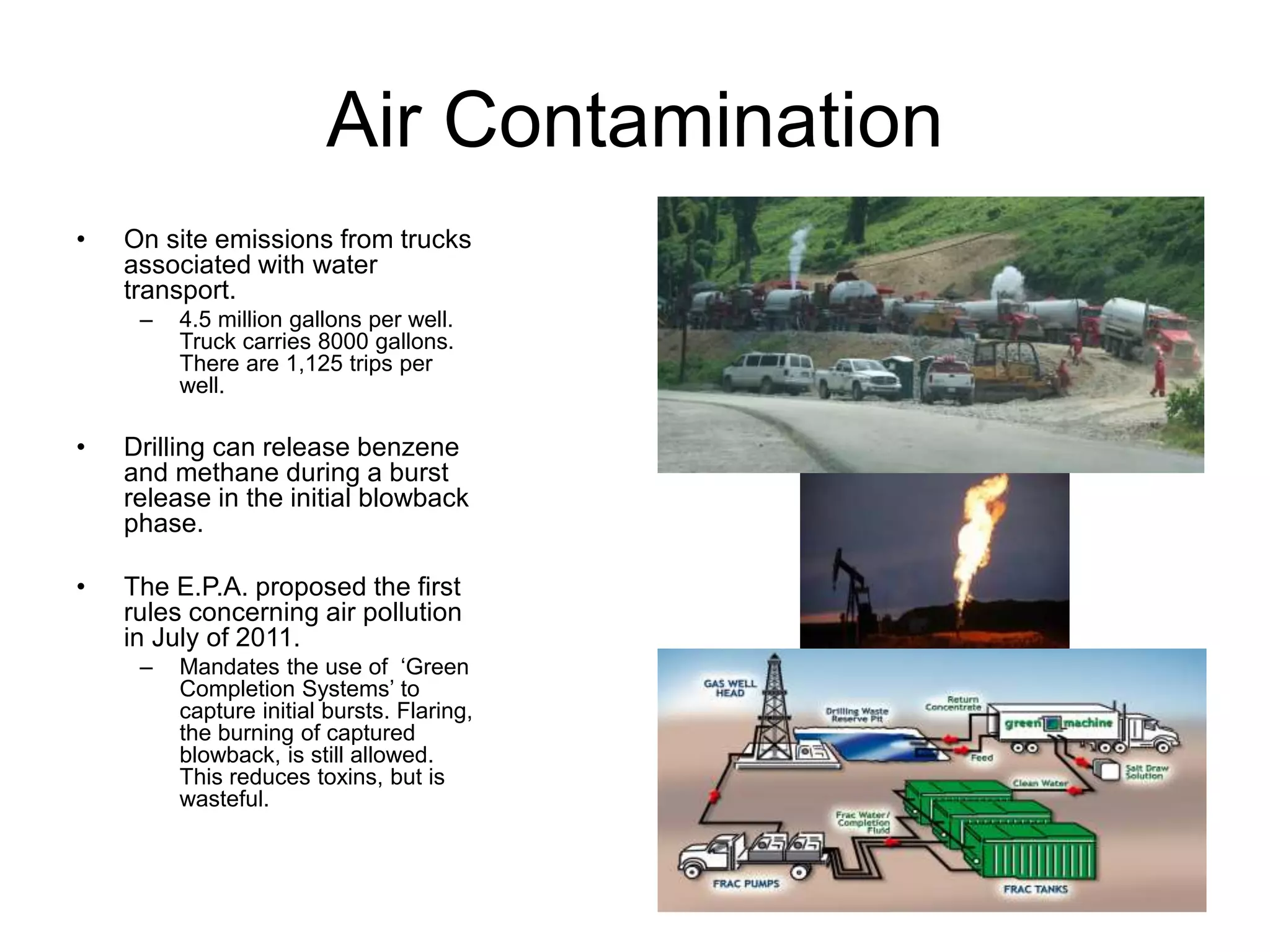

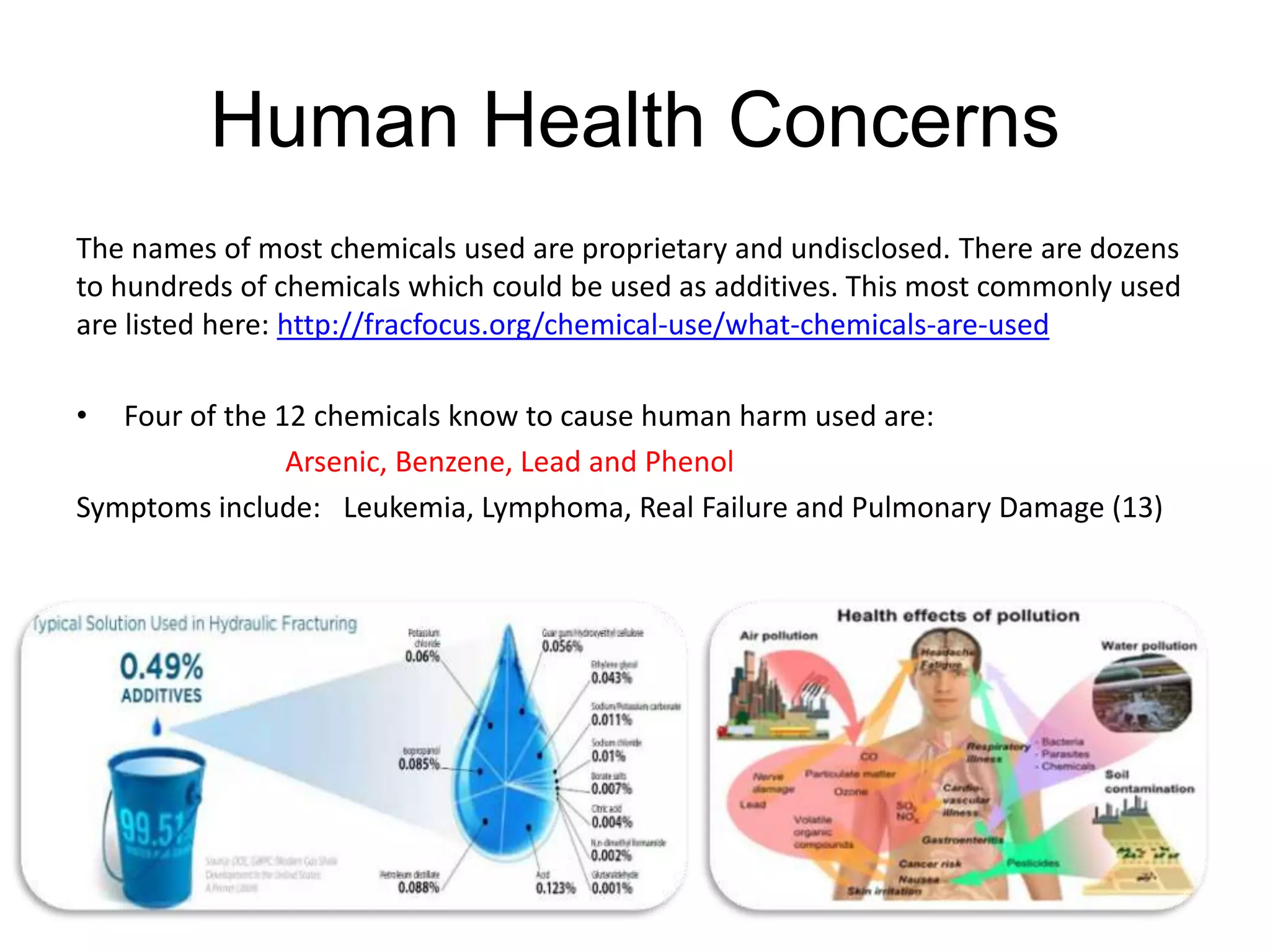

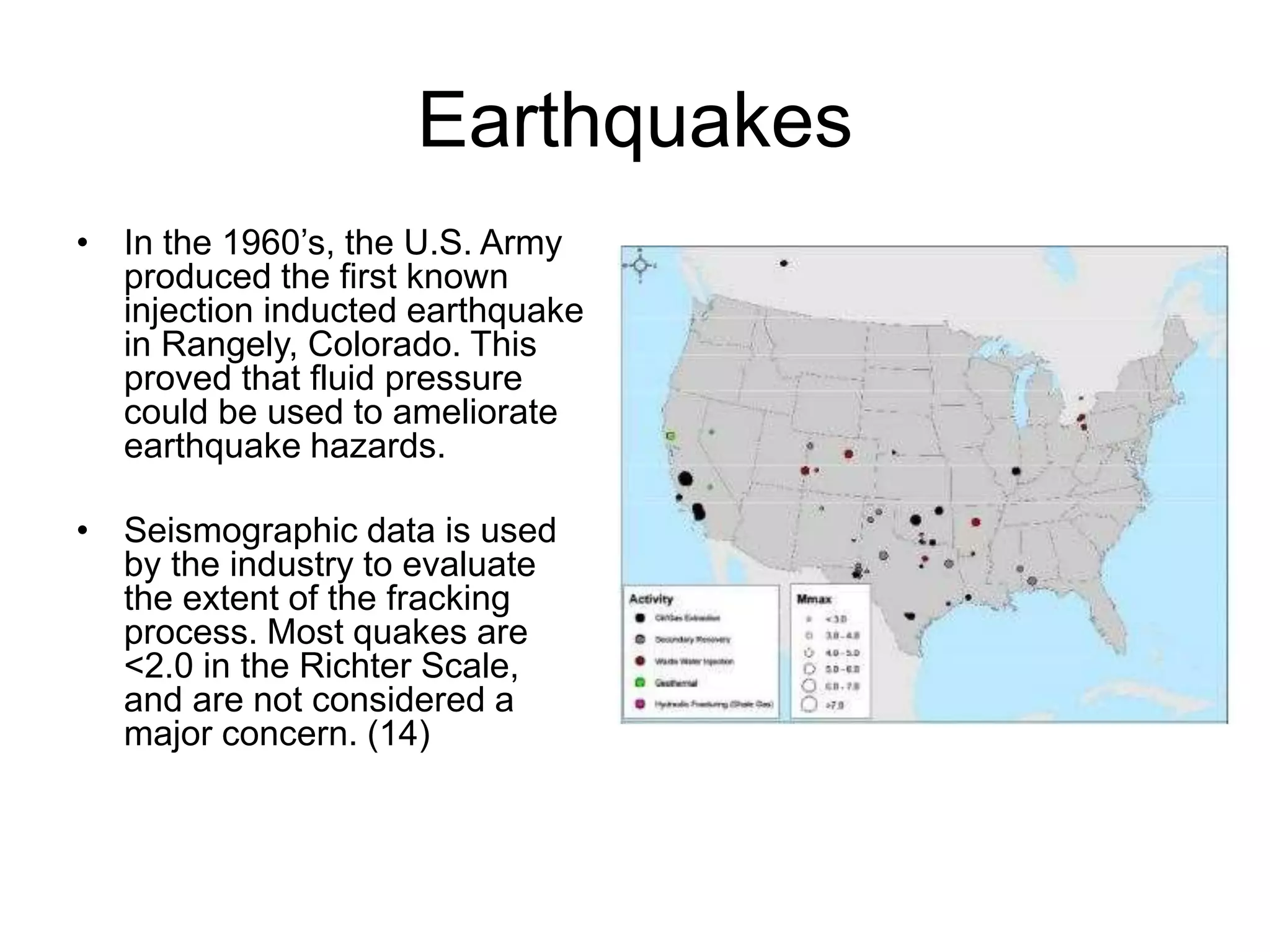

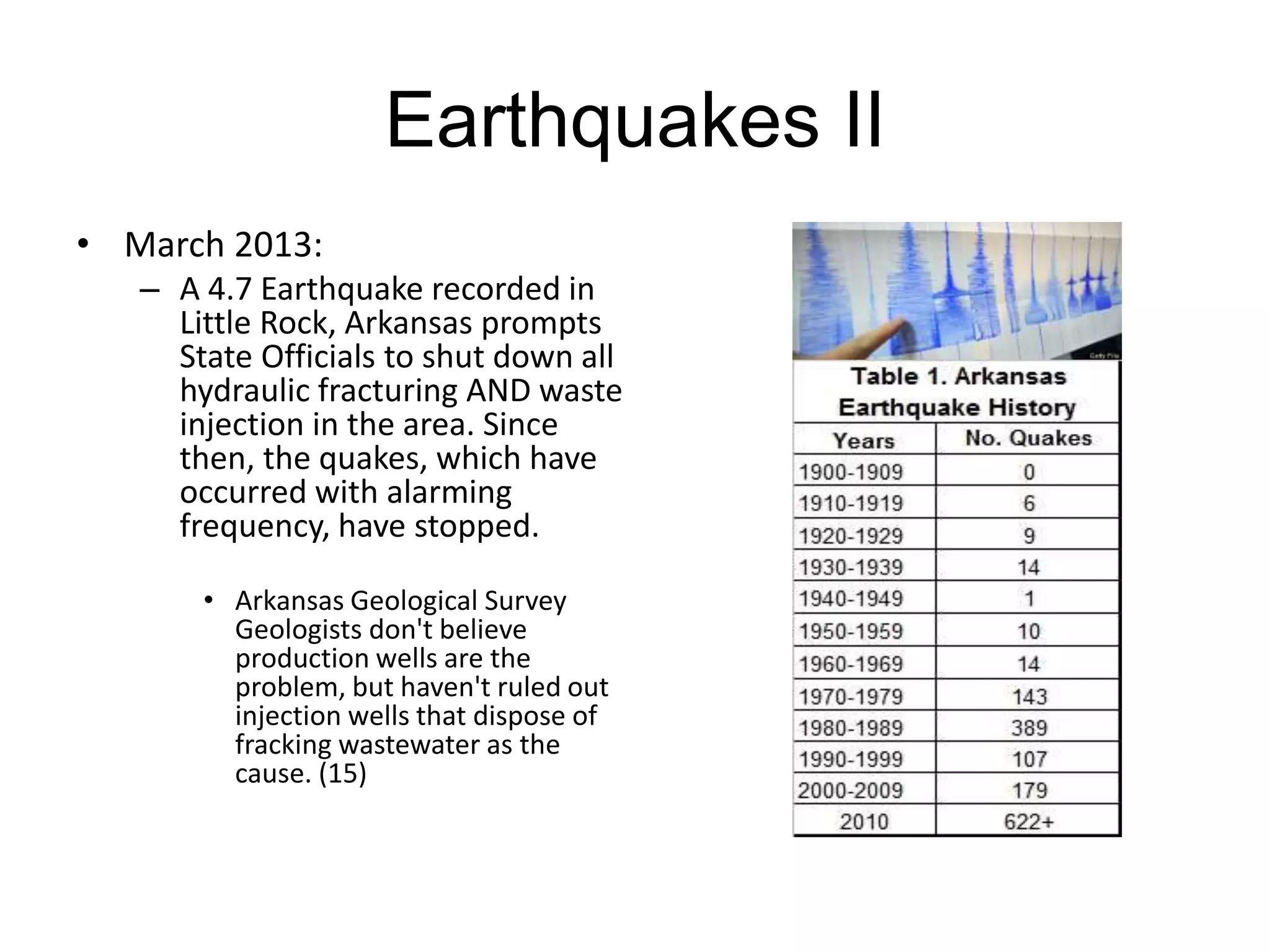

Hydraulic fracturing, also known as fracking, involves injecting fluid into shale rock formations to force open cracks and allow natural gas and oil to flow out. While fracking has increased US energy independence and reduced coal use, it also poses risks to the environment and public health. Fracking requires large amounts of water and chemicals and has been linked to groundwater contamination, air pollution, increased seismic activity, and health issues in humans and animals. However, replacing coal plants with natural gas could significantly reduce greenhouse gas emissions while more renewable technologies are developed. The dangers of fracking must be weighed against its current role in transitioning from coal to cleaner energy sources over the long run.