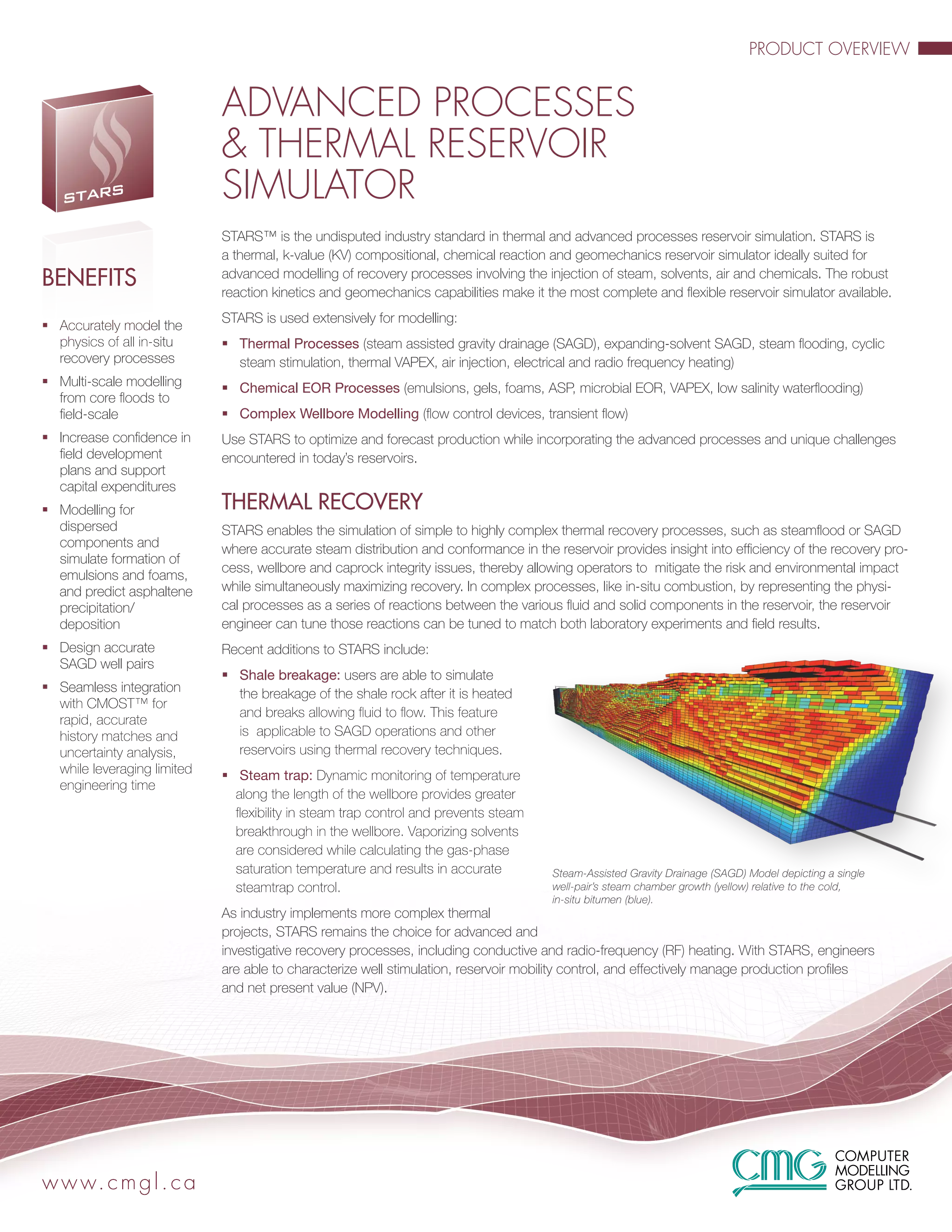

This document provides an overview of the STARS reservoir simulation software from CMG. STARS can accurately model various thermal and enhanced oil recovery processes at multiple scales from core floods to field-scale. It allows users to optimize field development plans, model complex wellbore designs, simulate formation of emulsions and foams, and predict asphaltene precipitation. STARS remains the industry standard for simulating thermal recovery processes like SAGD and steamflooding as well as chemical EOR processes through its robust reaction kinetics and ability to mechanistically model physical processes.