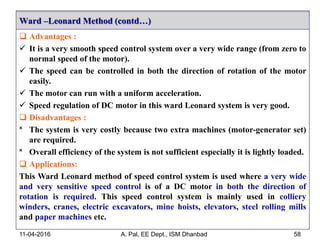

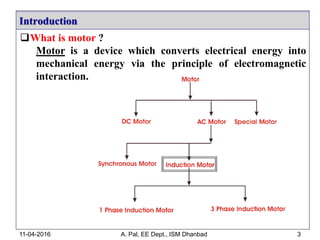

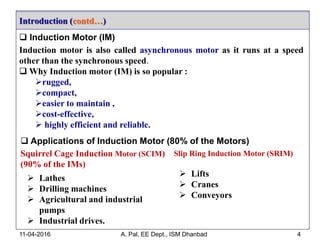

This document provides an overview of induction motors, including their working principles, characteristics, starting methods, speed control methods, and applications in variable speed drives. Some key points:

- Induction motors are widely used in industry due to their ruggedness, low cost, and high efficiency. They make up around 80% of all electric motors.

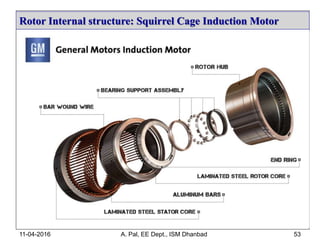

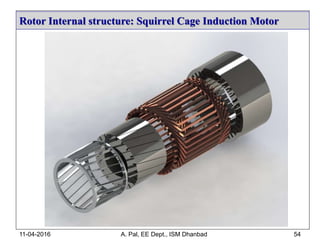

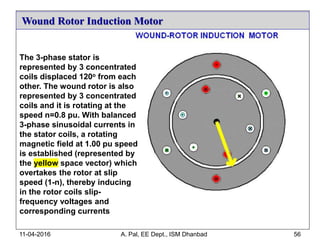

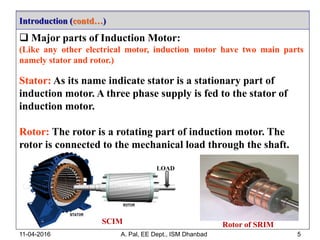

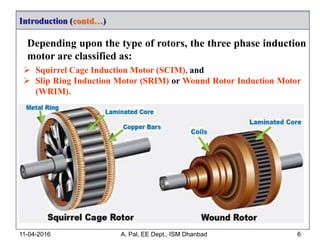

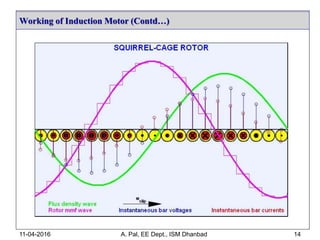

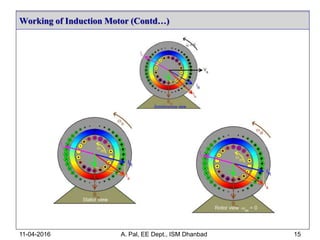

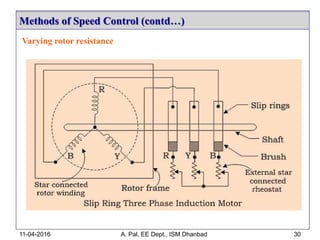

- The motor consists of a stationary stator and a rotating rotor. Depending on the rotor type, induction motors are classified as squirrel cage or slip ring motors.

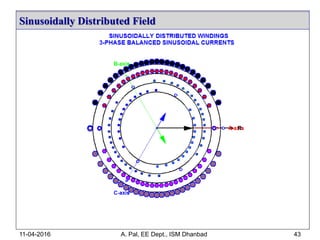

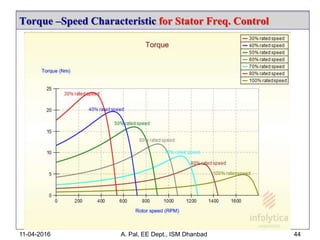

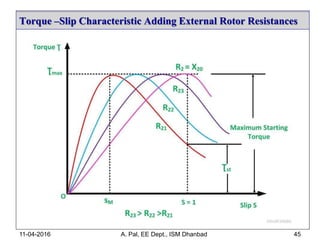

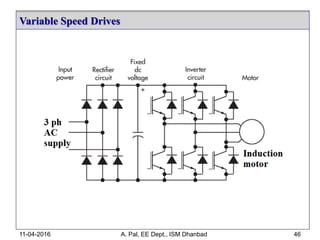

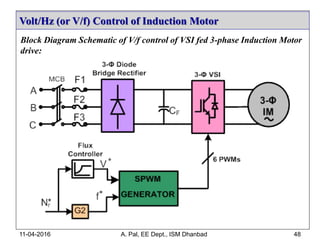

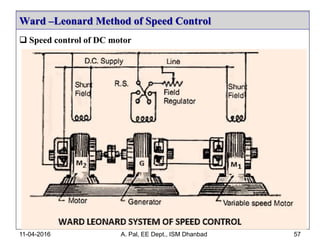

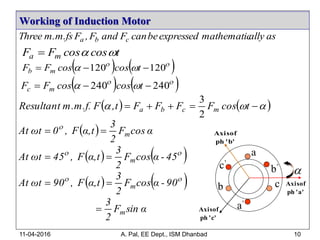

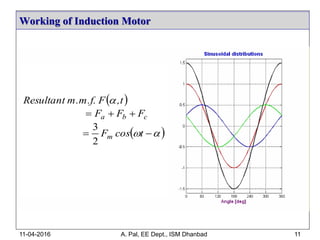

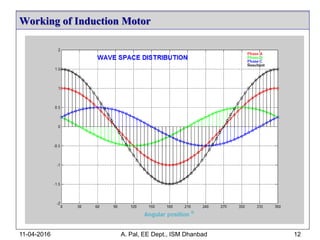

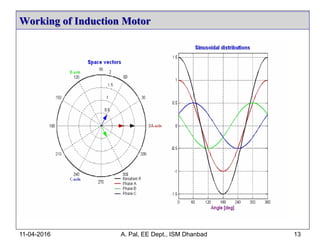

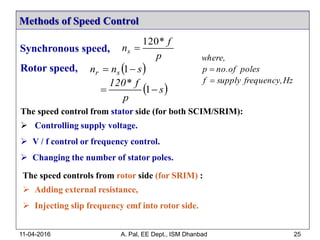

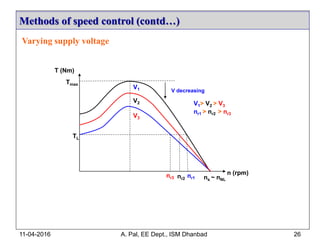

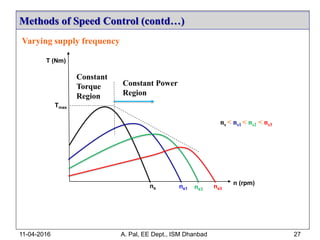

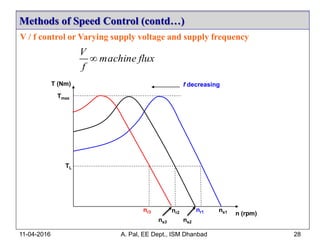

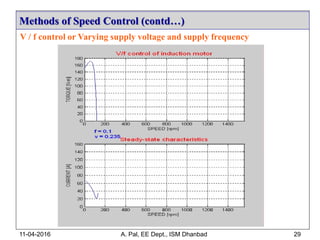

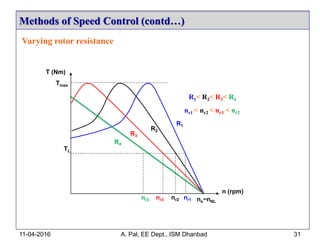

- A rotating magnetic field is produced in the stator by a three-phase supply. This induces currents in the rotor and generates torque. Speed is controlled by varying supply voltage, frequency, or rotor

![Working of Induction Motor

11-04-2016 A. Pal, EE Dept., ISM Dhanbad 8

a Fc

-93 10 113 216

-1.5

-1

-0.5

0

0.5

1

1.5

a’

c’

b’

b c

a

a’

c’ b’

b

c

a

a’

c’

b’

b c

a

a’

c’

b’

b c

Fb

Fb

FcFb

Fc Fc Fb

Space angle () in degrees

Fc

Fb

t = t0= t4

t = t1

t = t2 t = t3

t = t0= t4

RMF (Rotating Magnetic Field) [video link]](https://image.slidesharecdn.com/imabhisekpal-160411053406/85/Induction-Motor-8-320.jpg)

![Working of Induction Motor

11-04-2016 A. Pal, EE Dept., ISM Dhanbad 9

RMF (Rotating Magnetic Field) [video link]](https://image.slidesharecdn.com/imabhisekpal-160411053406/85/Induction-Motor-9-320.jpg)

![Reference

[1] M. G. Say, Alternating current machines, Pitman, 4th Ed., 1976.

[2] D. P. Kothari and I. J. Nagrath, Electric machines, Tata McGraw Hill, 2010.

[3] P. S. Bimbhra, Electrical machinery, Kaanna Publishers, 2010.

[4] B. K. Bose, Modern power electronics and ac drives, Prentice Hall, 2002.

[5] Electrical4u.com, ‘Electrical Engineering and Technology’, 2016. [Online].

Available: http://www.electrical4u.com/working-principle-of-three-phase-

induction-motor. [Accessed: 15- March- 2016].

11-04-2016 A. Pal, EE Dept., ISM Dhanbad 39](https://image.slidesharecdn.com/imabhisekpal-160411053406/85/Induction-Motor-39-320.jpg)