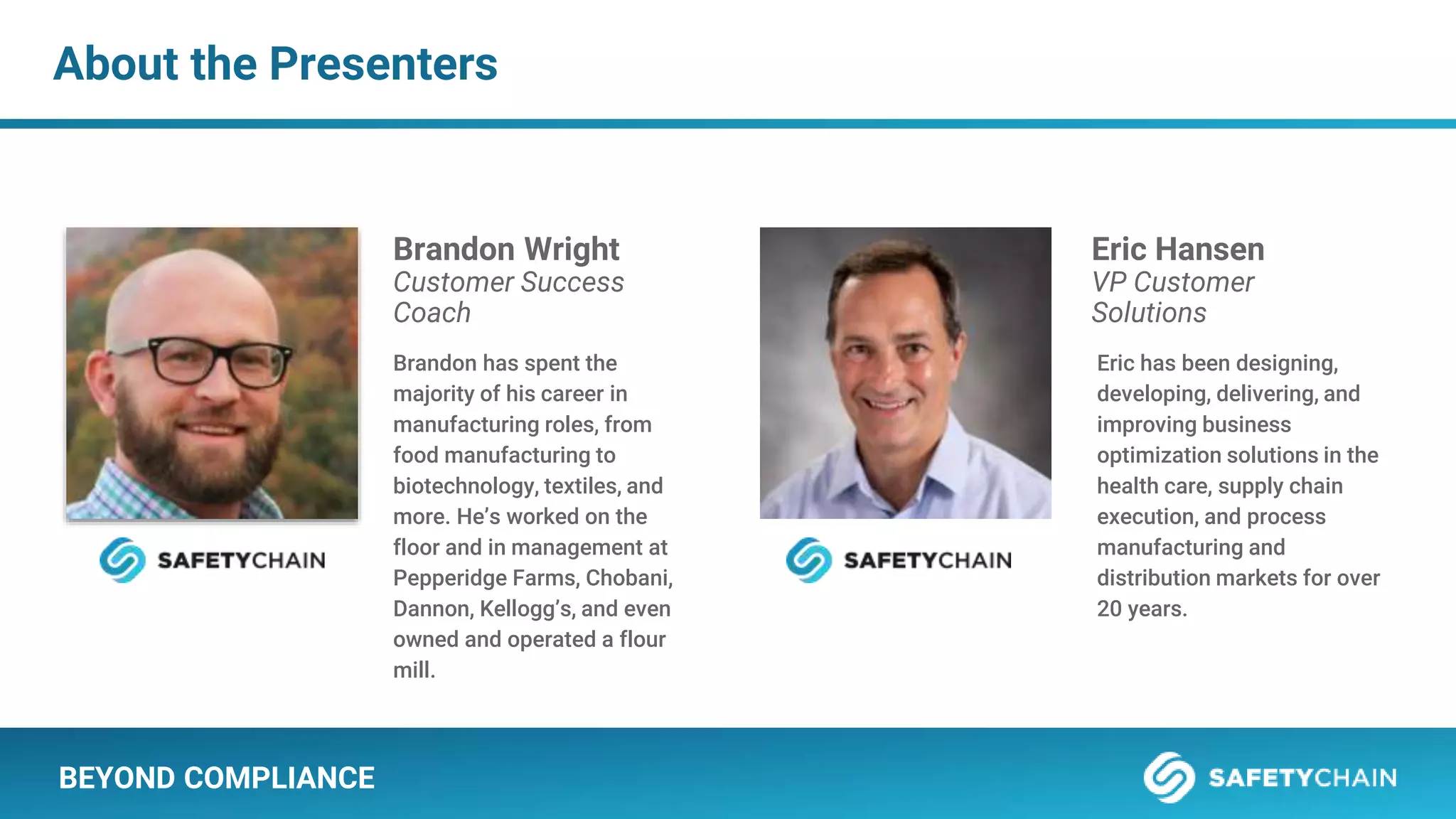

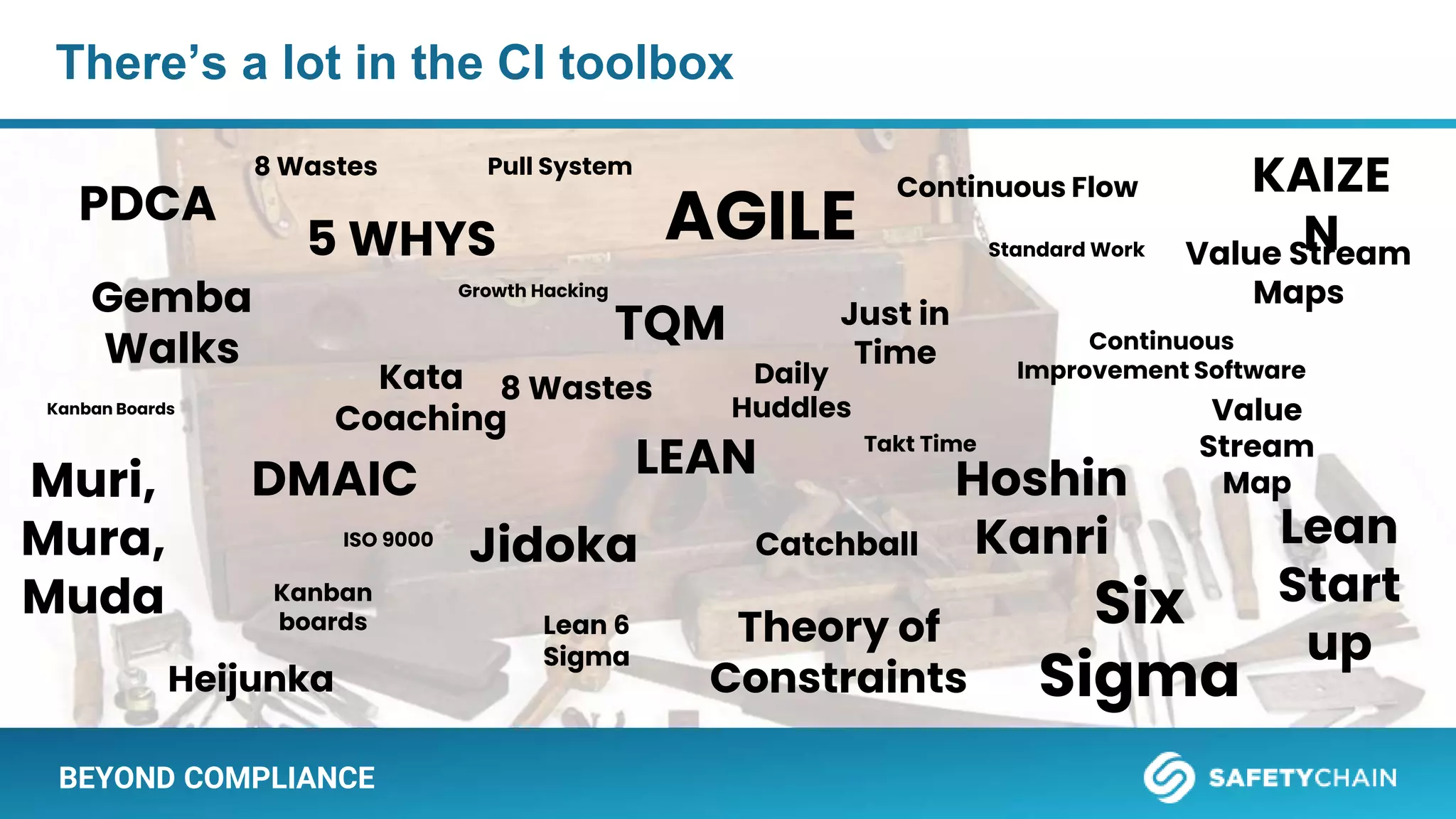

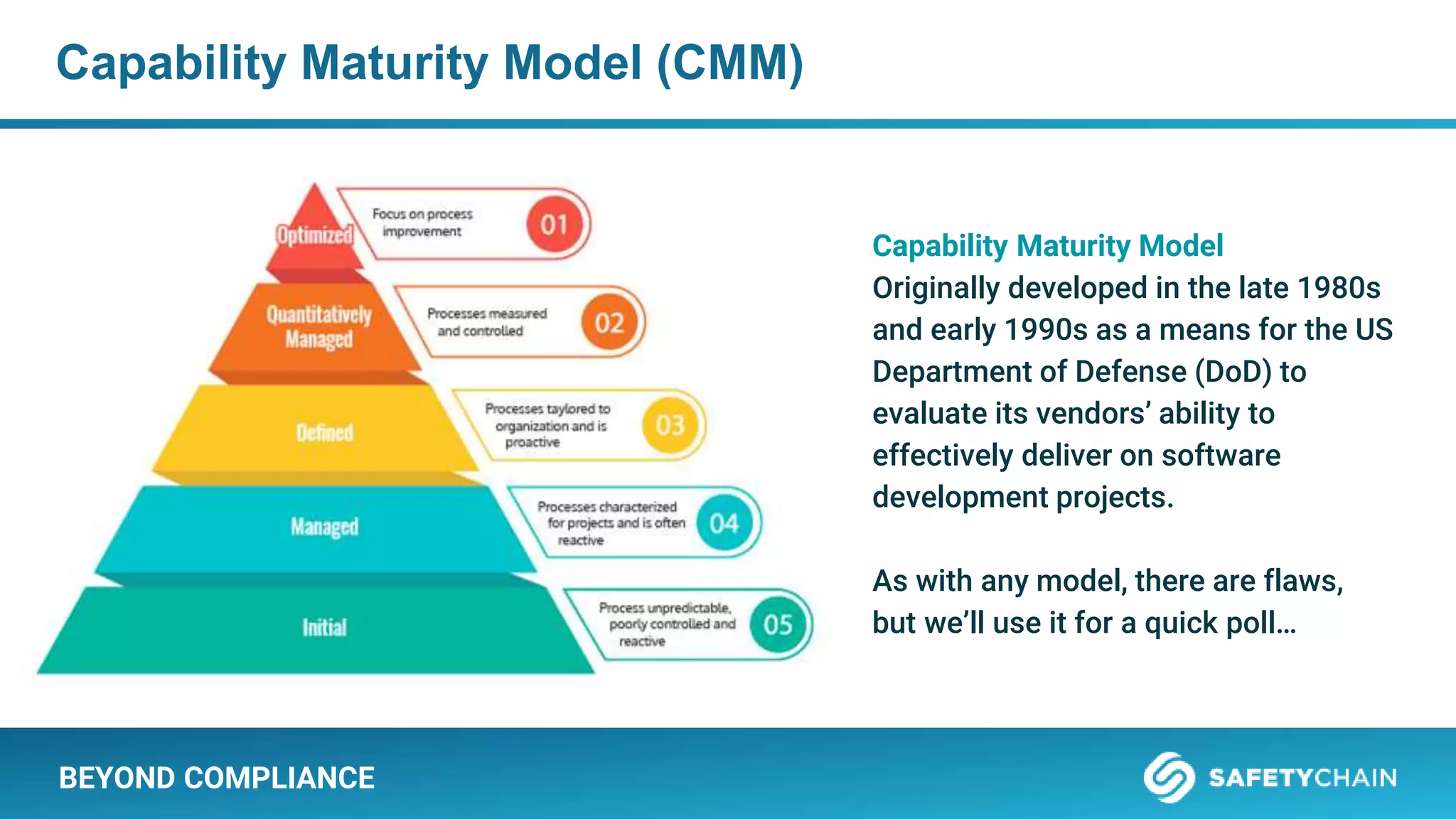

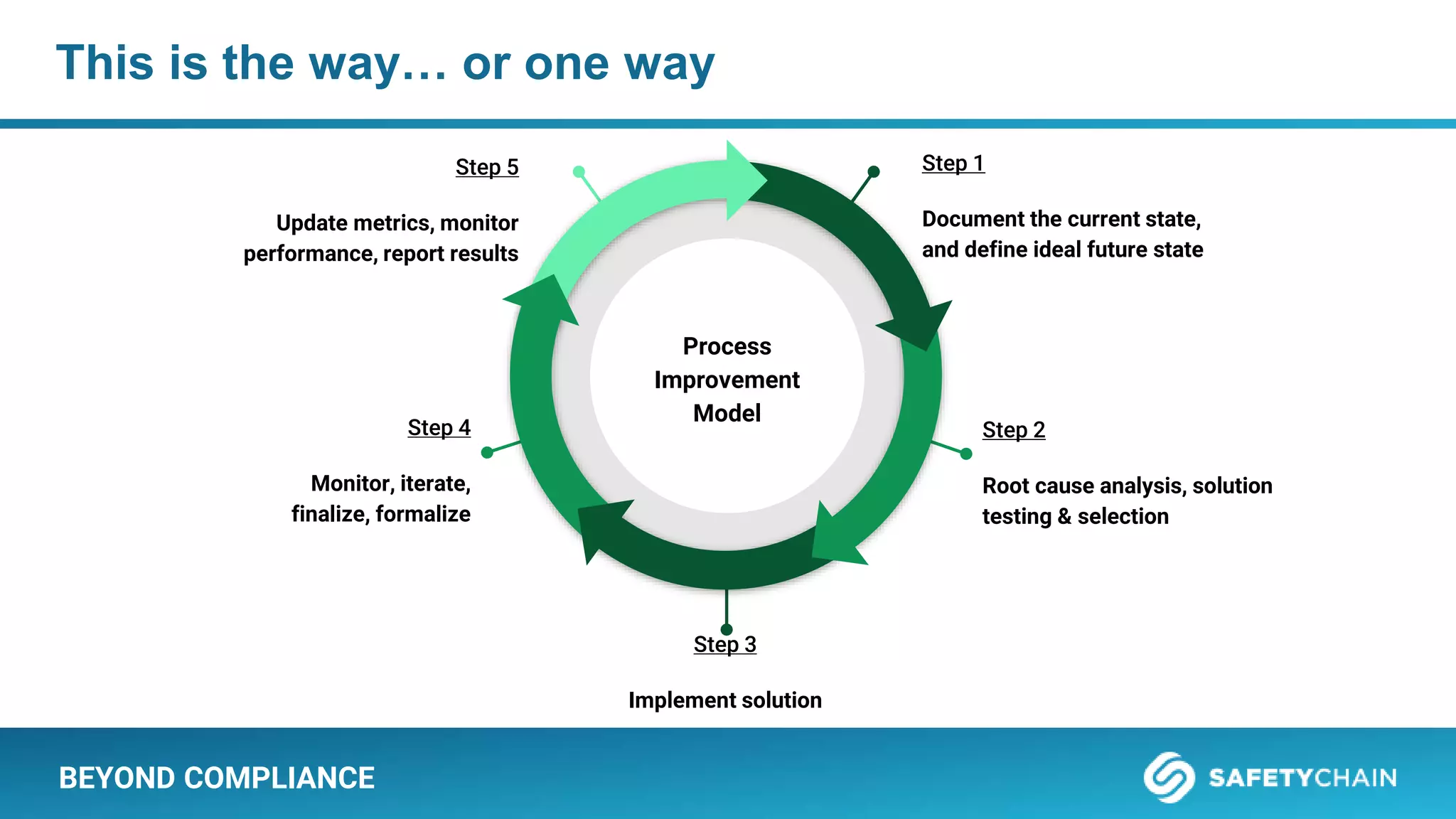

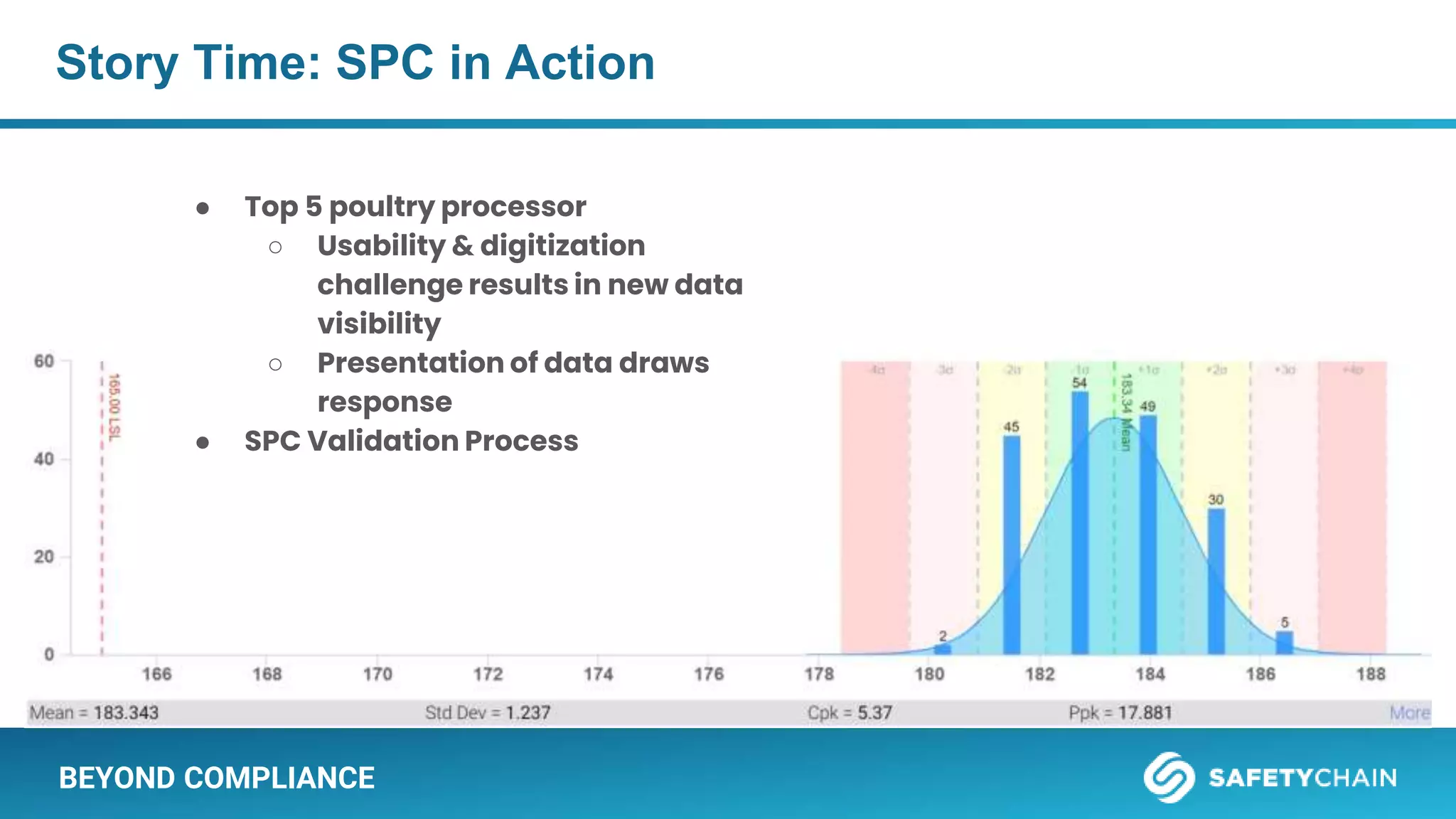

The document outlines a webinar and podcast series focused on continuous improvement methodologies for process manufacturers, led by experts Brandon Wright and Eric Hansen. It covers key strategies for improving yield and productivity, the implementation of various improvement techniques like the Theory of Constraints and Statistical Process Control, and emphasizes the importance of having a structured CI process. Additional resources and case studies are provided to support the adoption of continuous improvement practices.