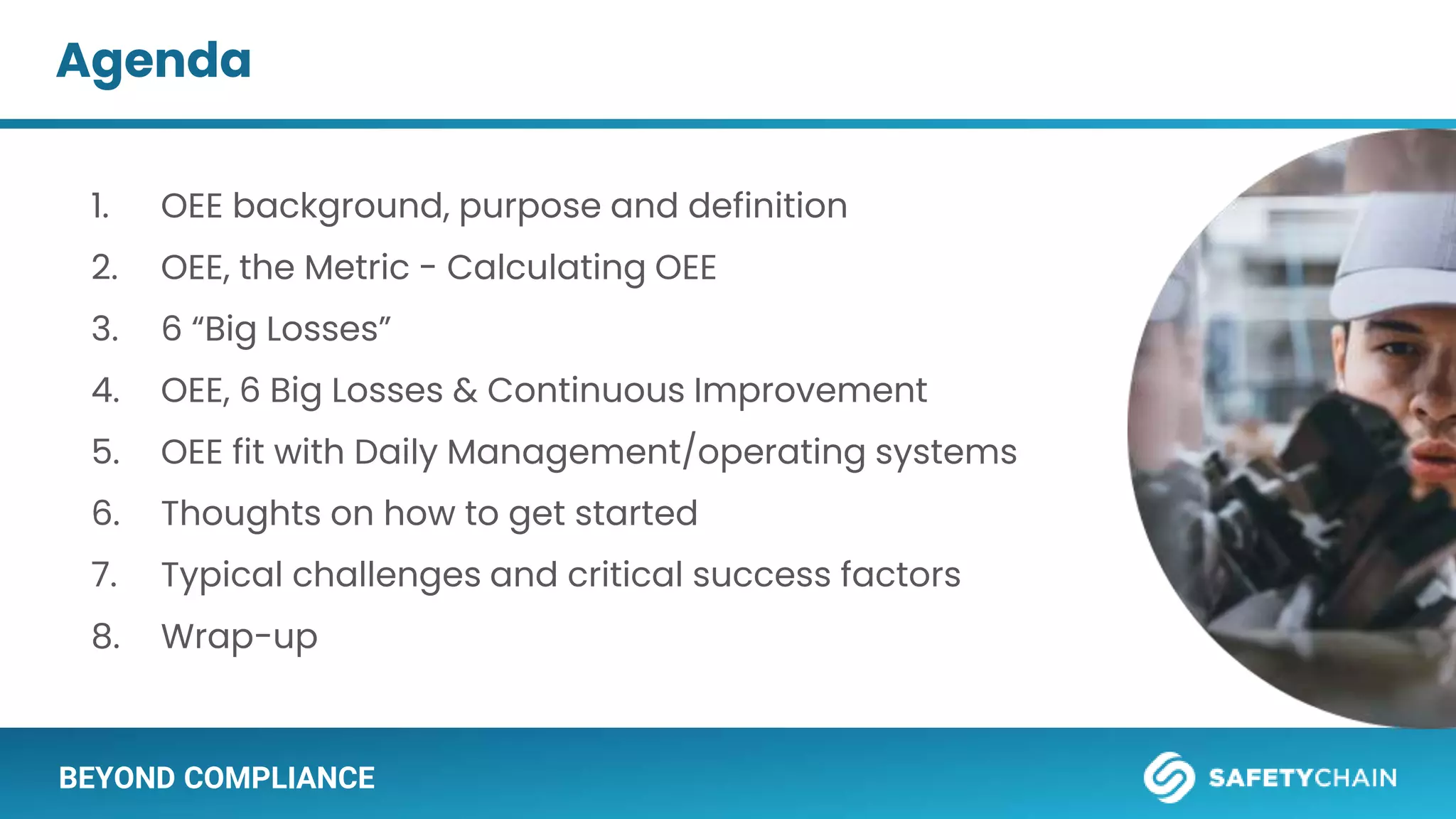

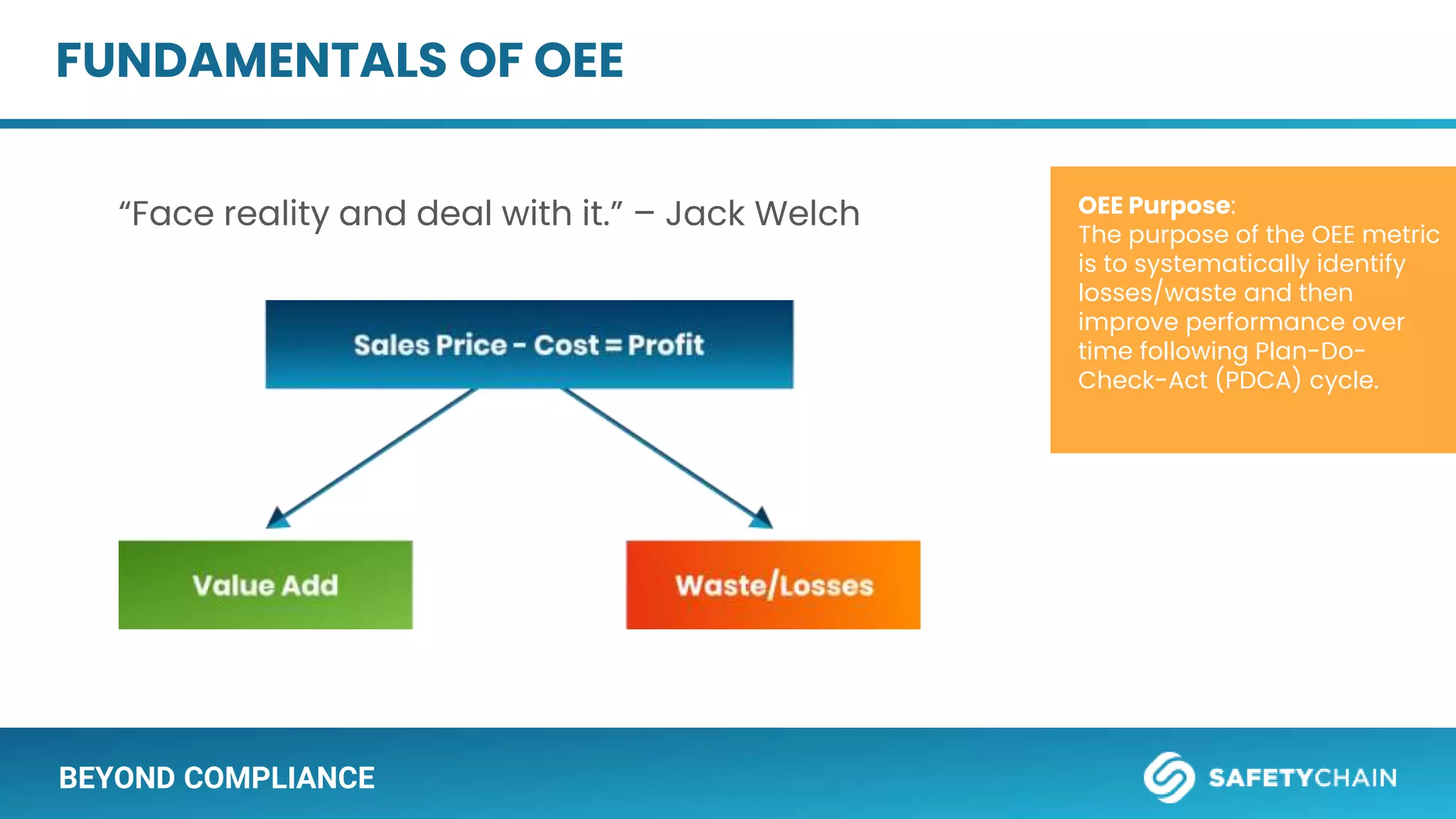

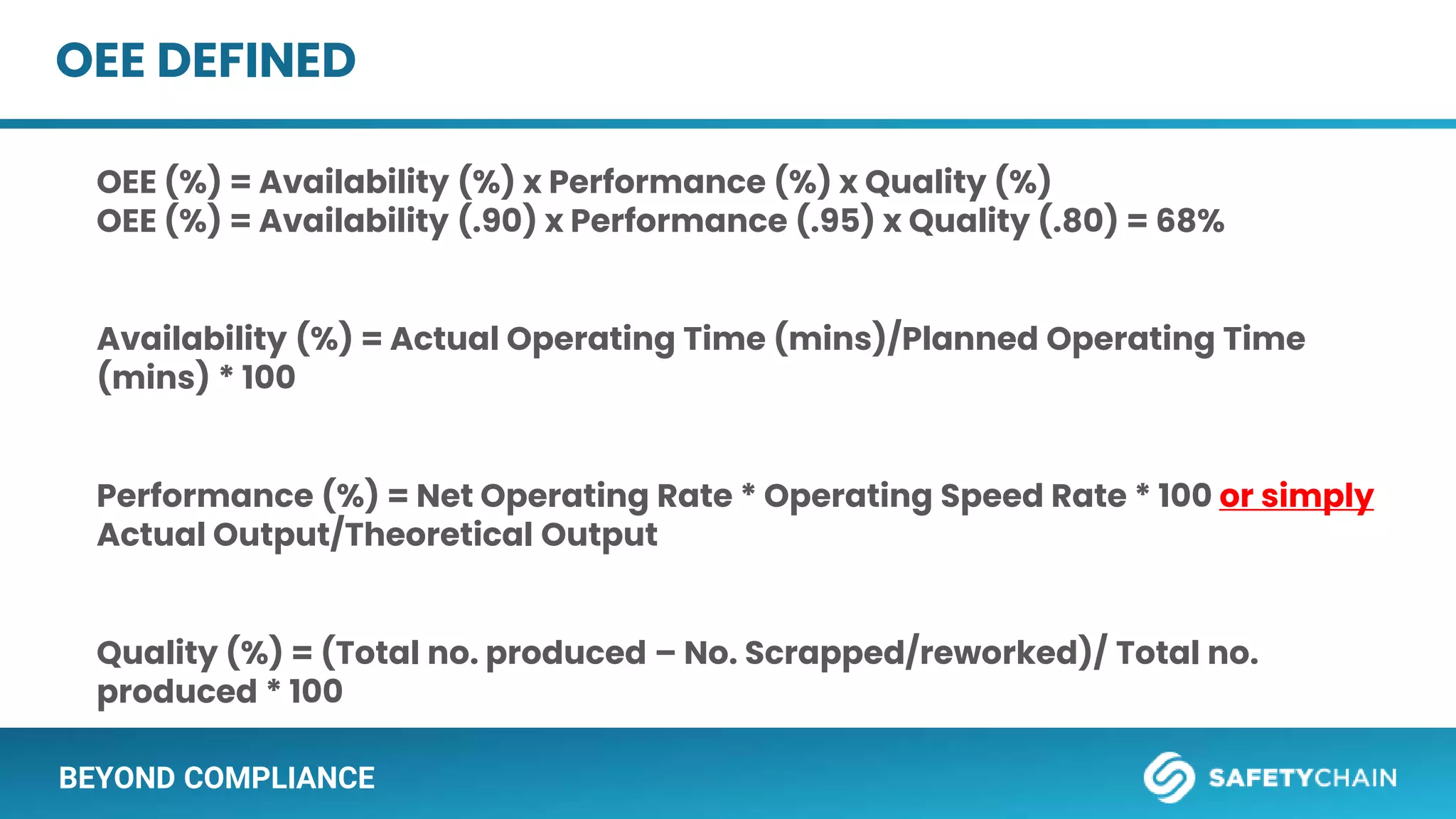

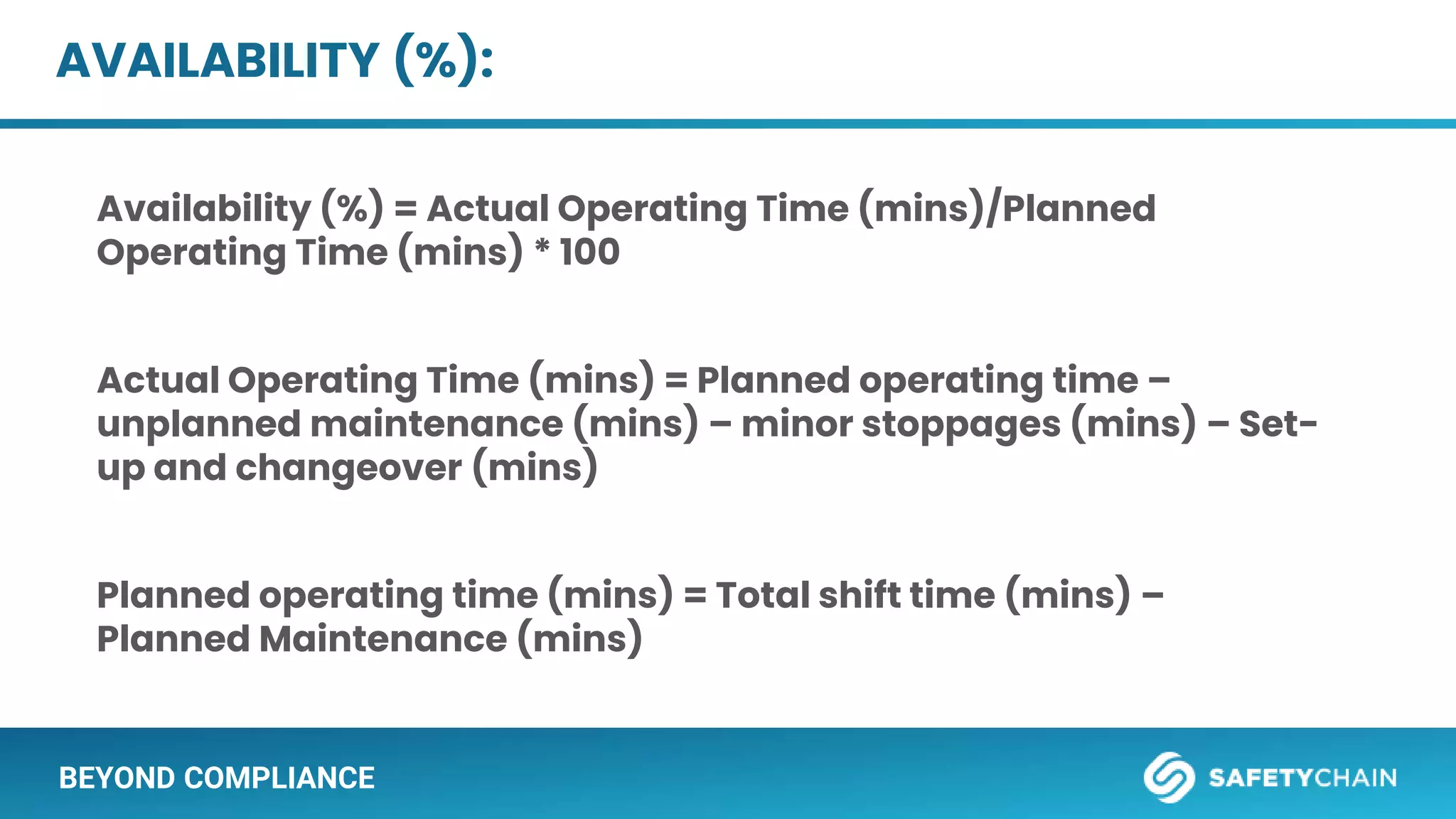

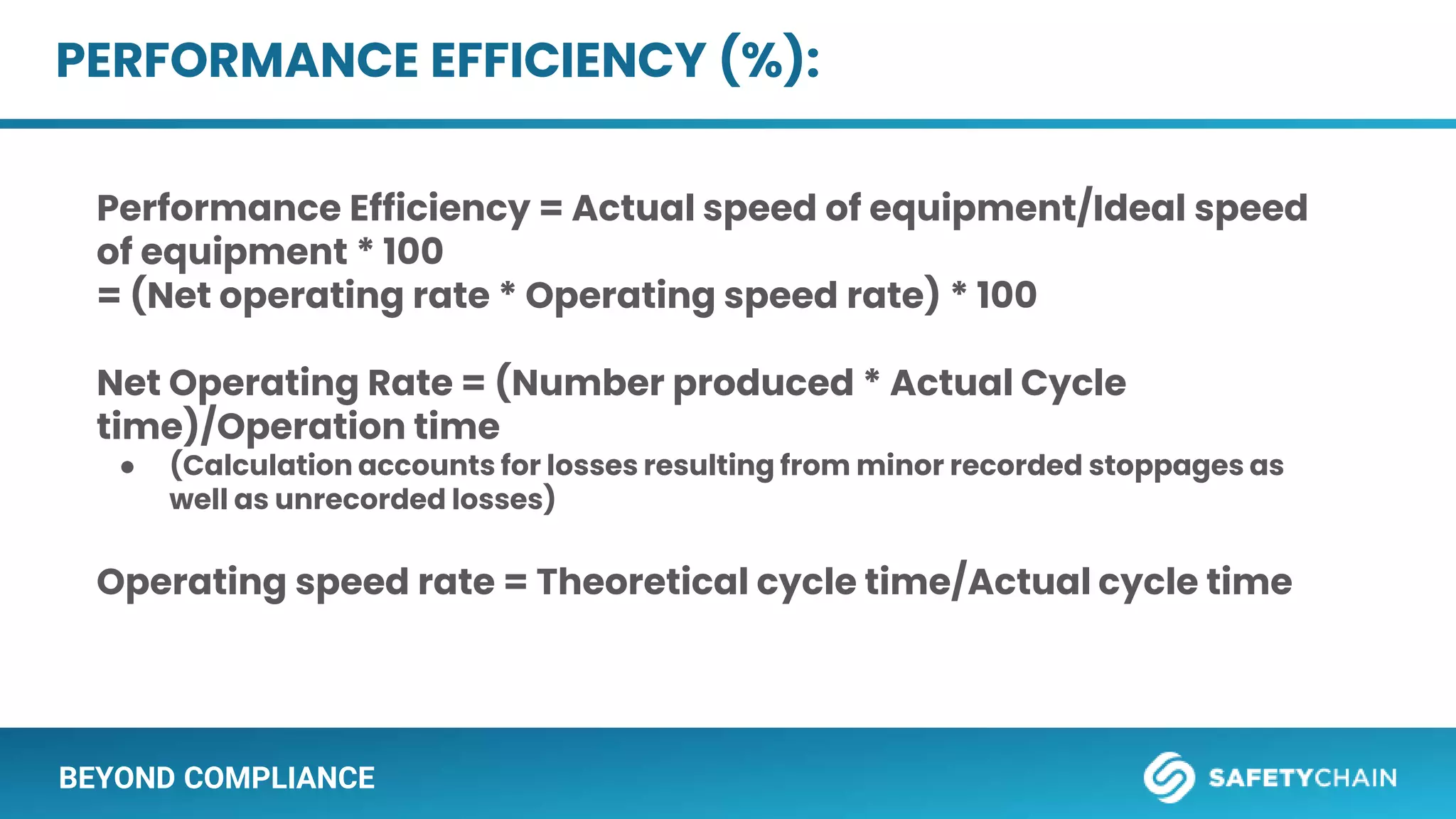

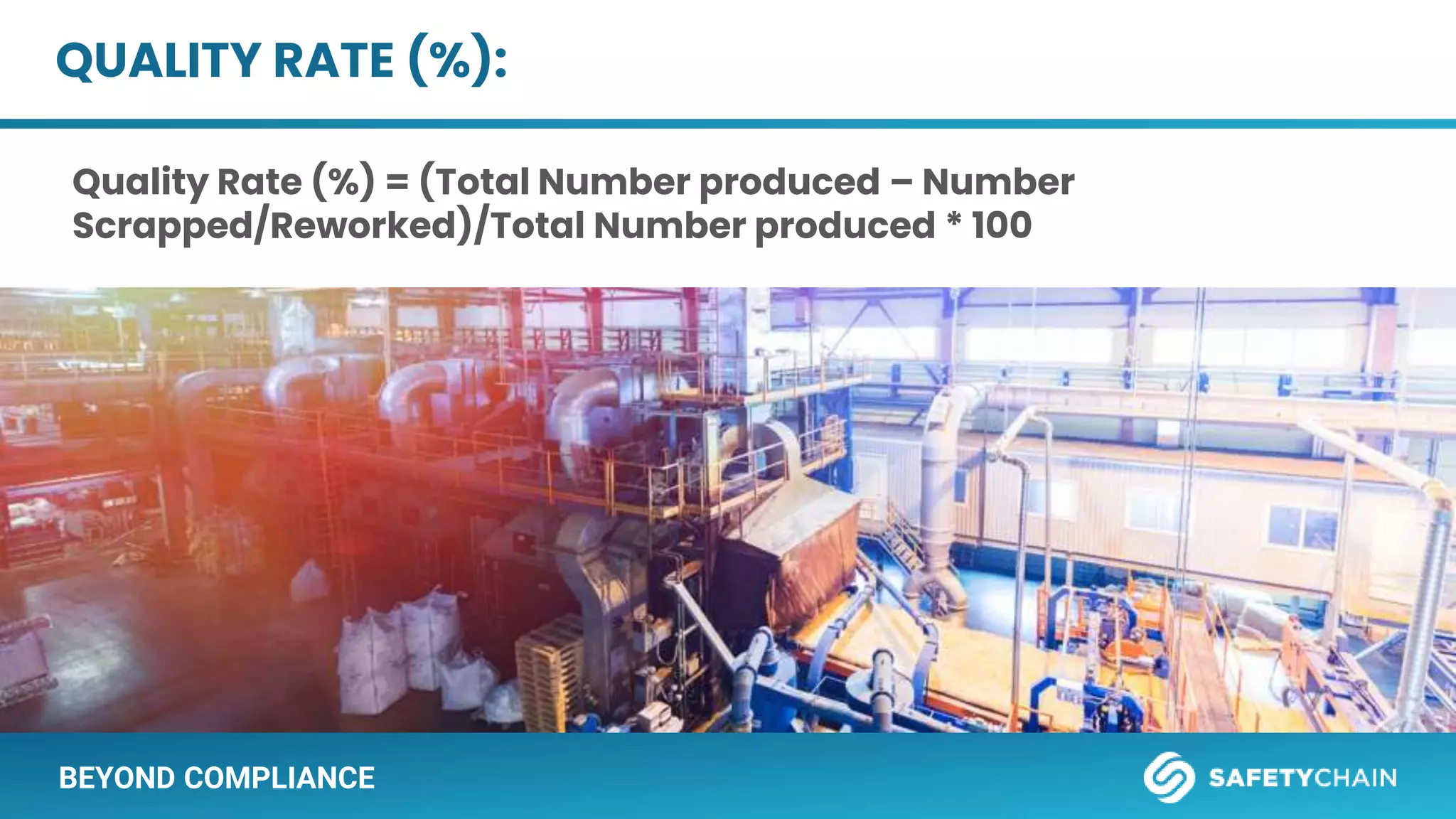

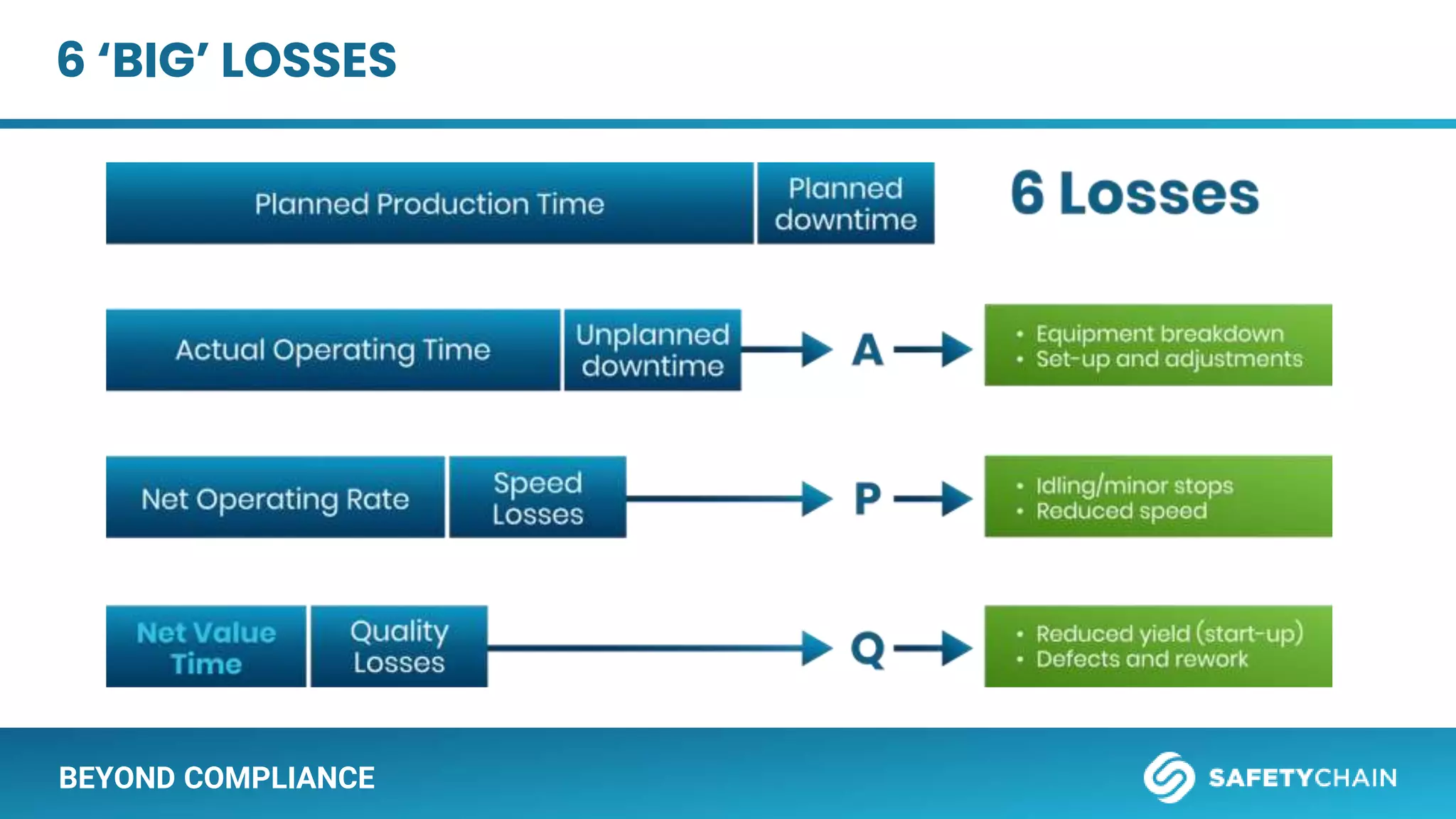

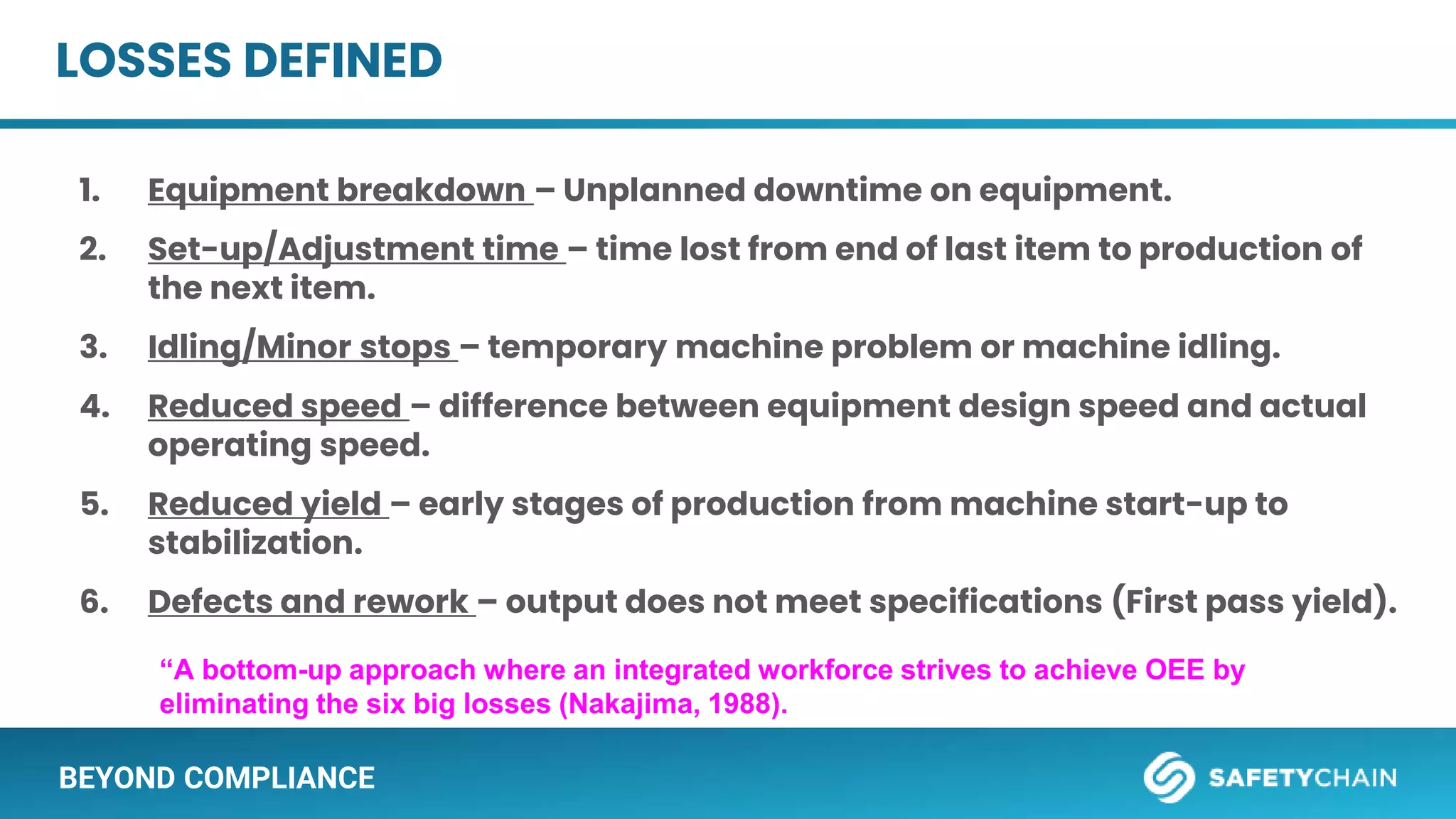

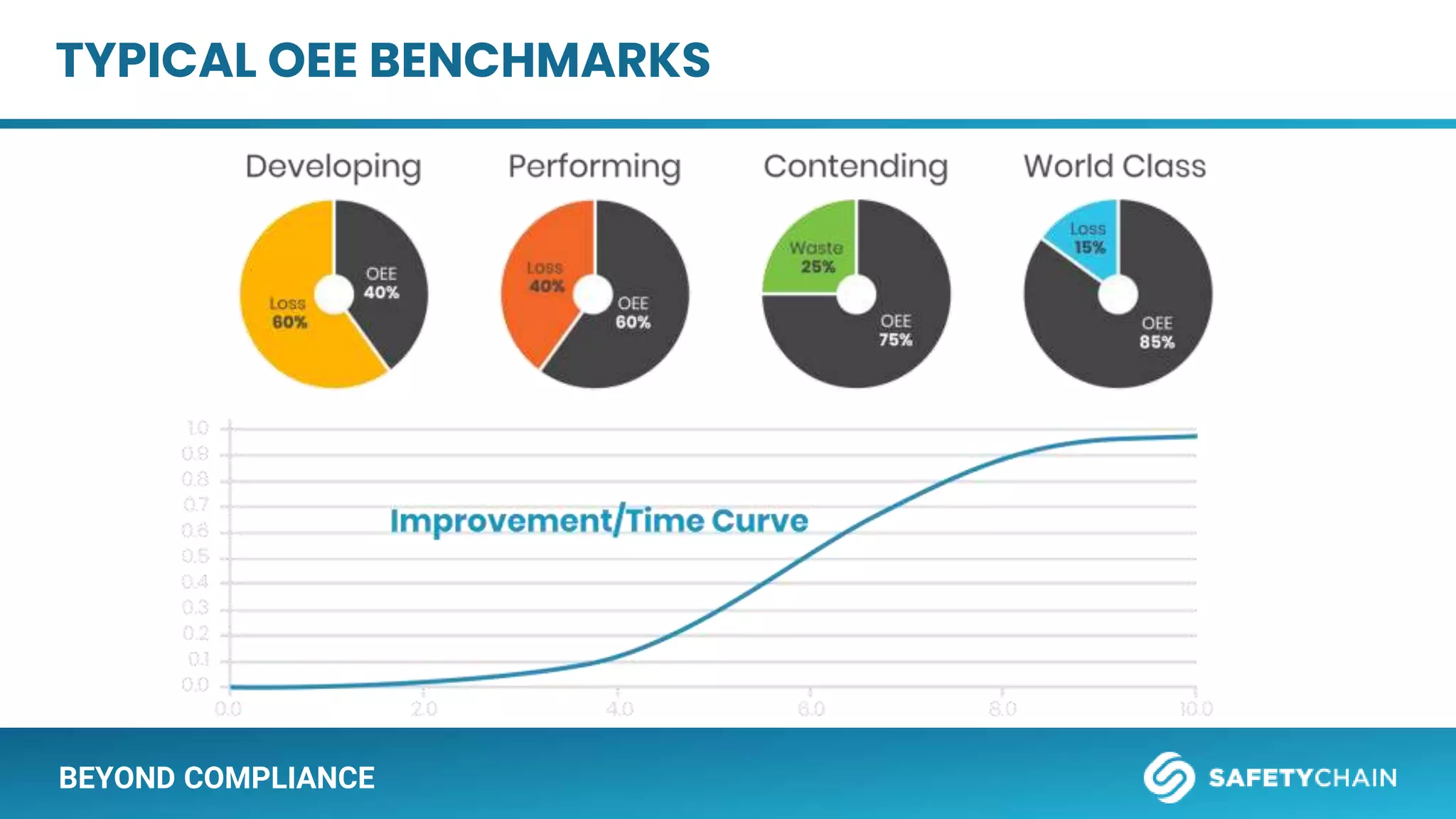

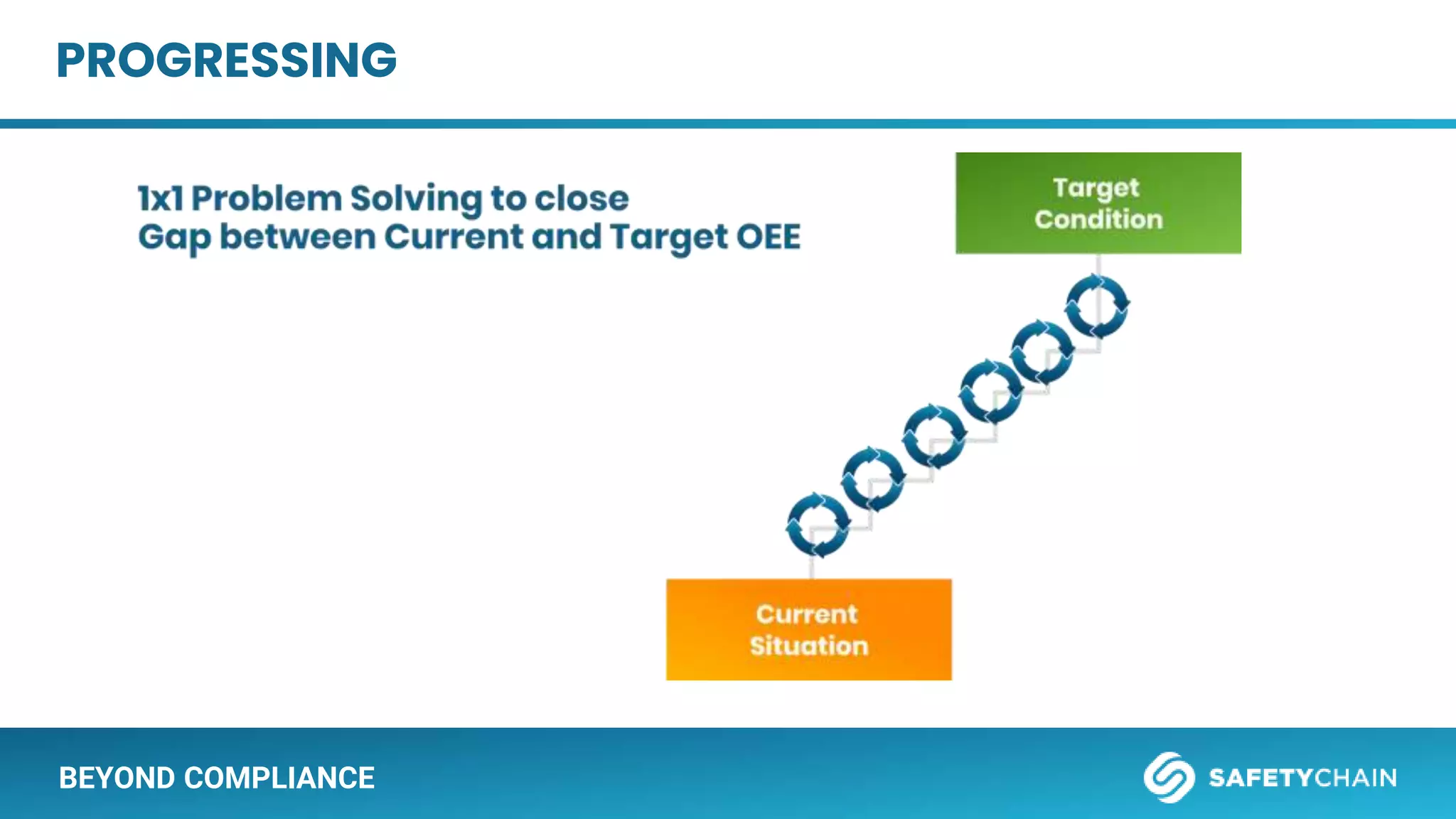

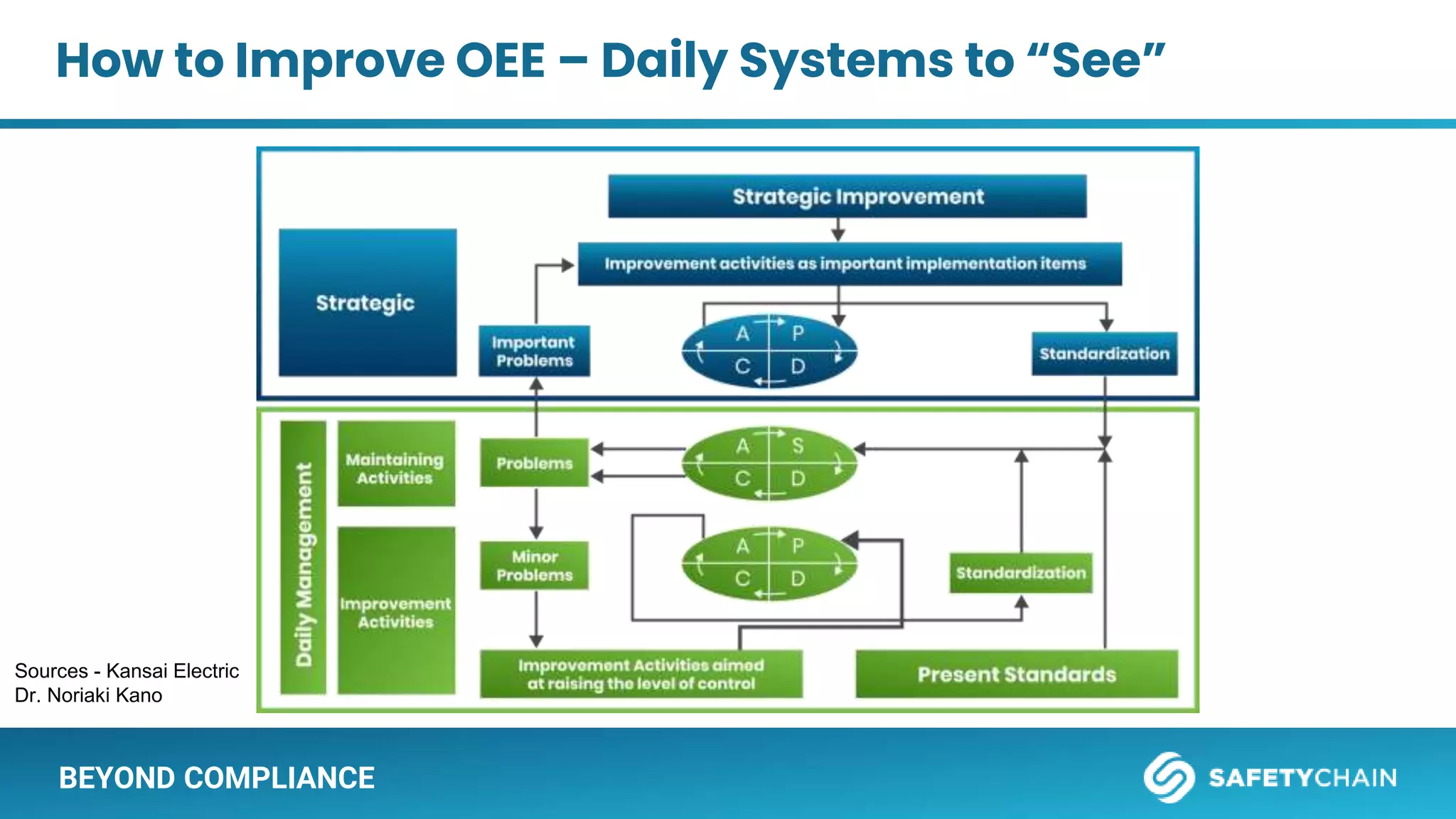

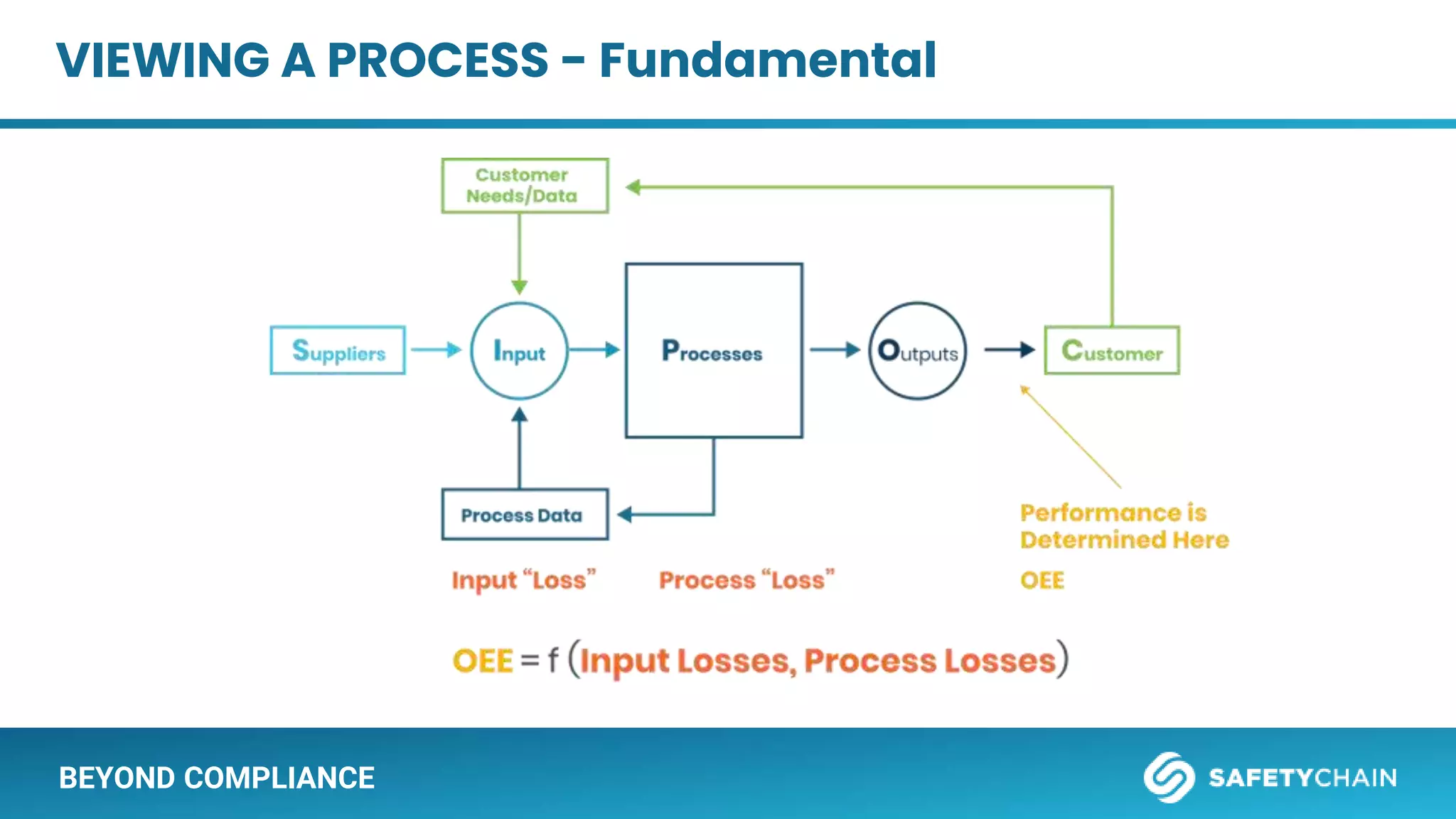

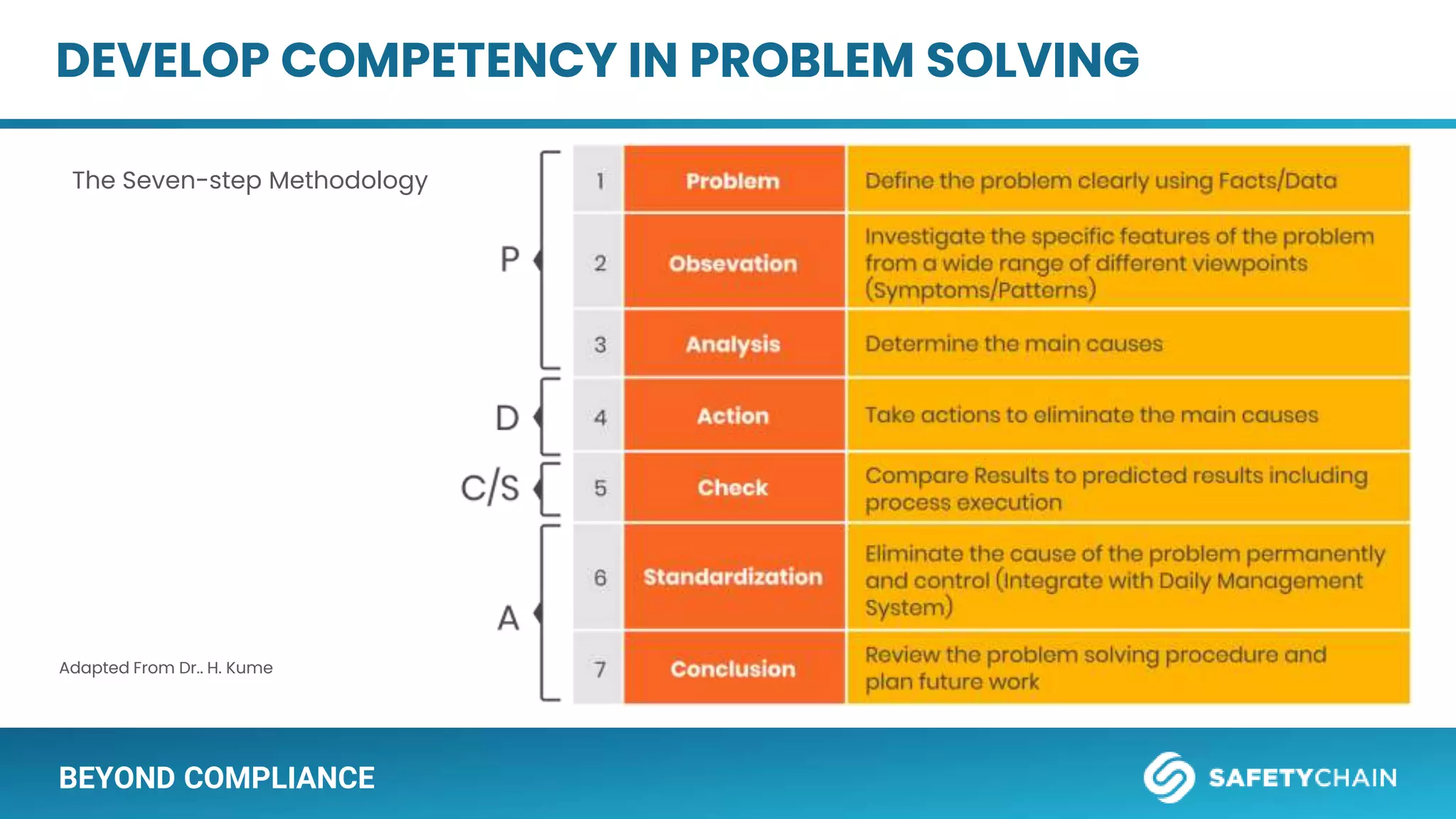

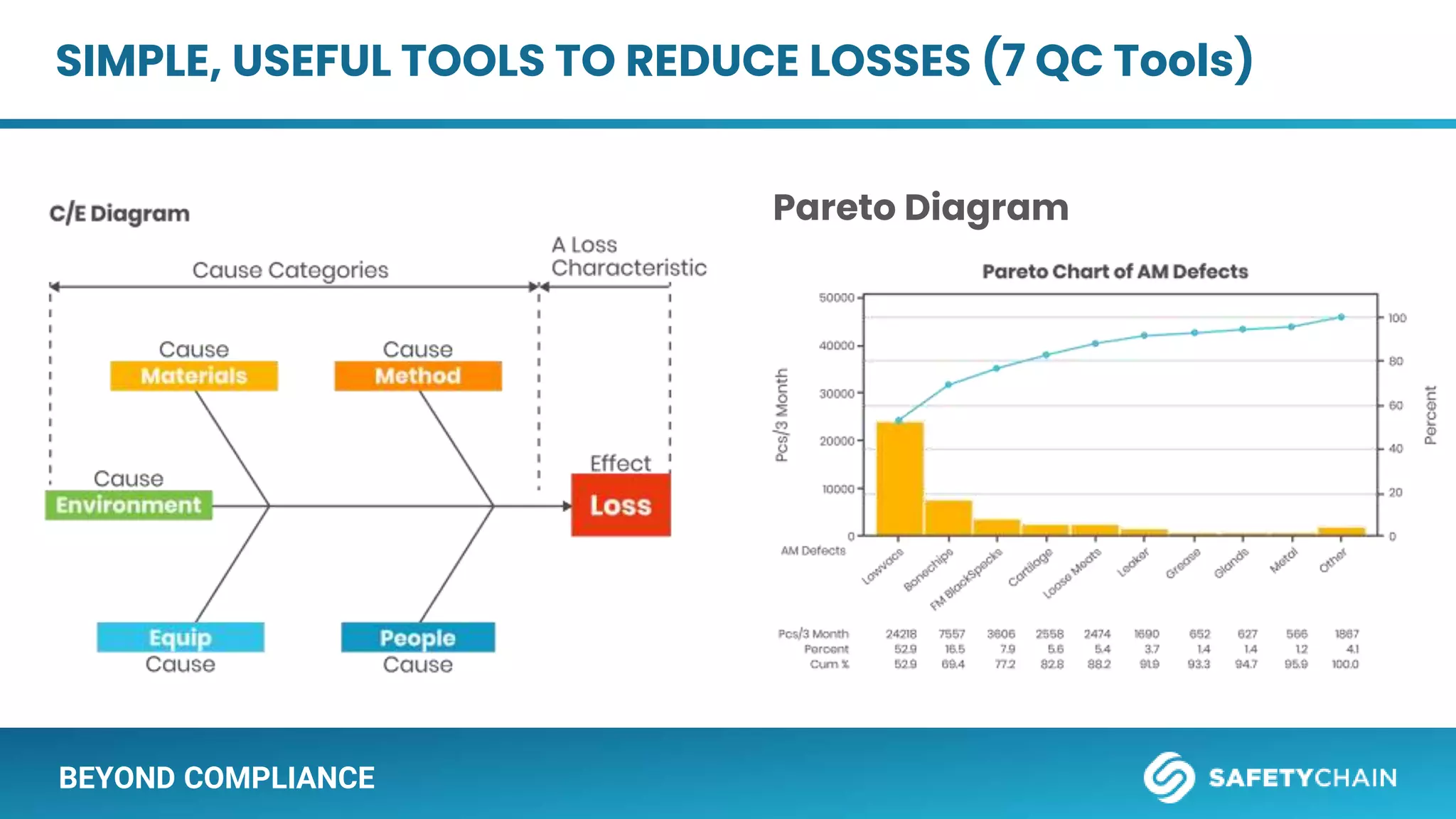

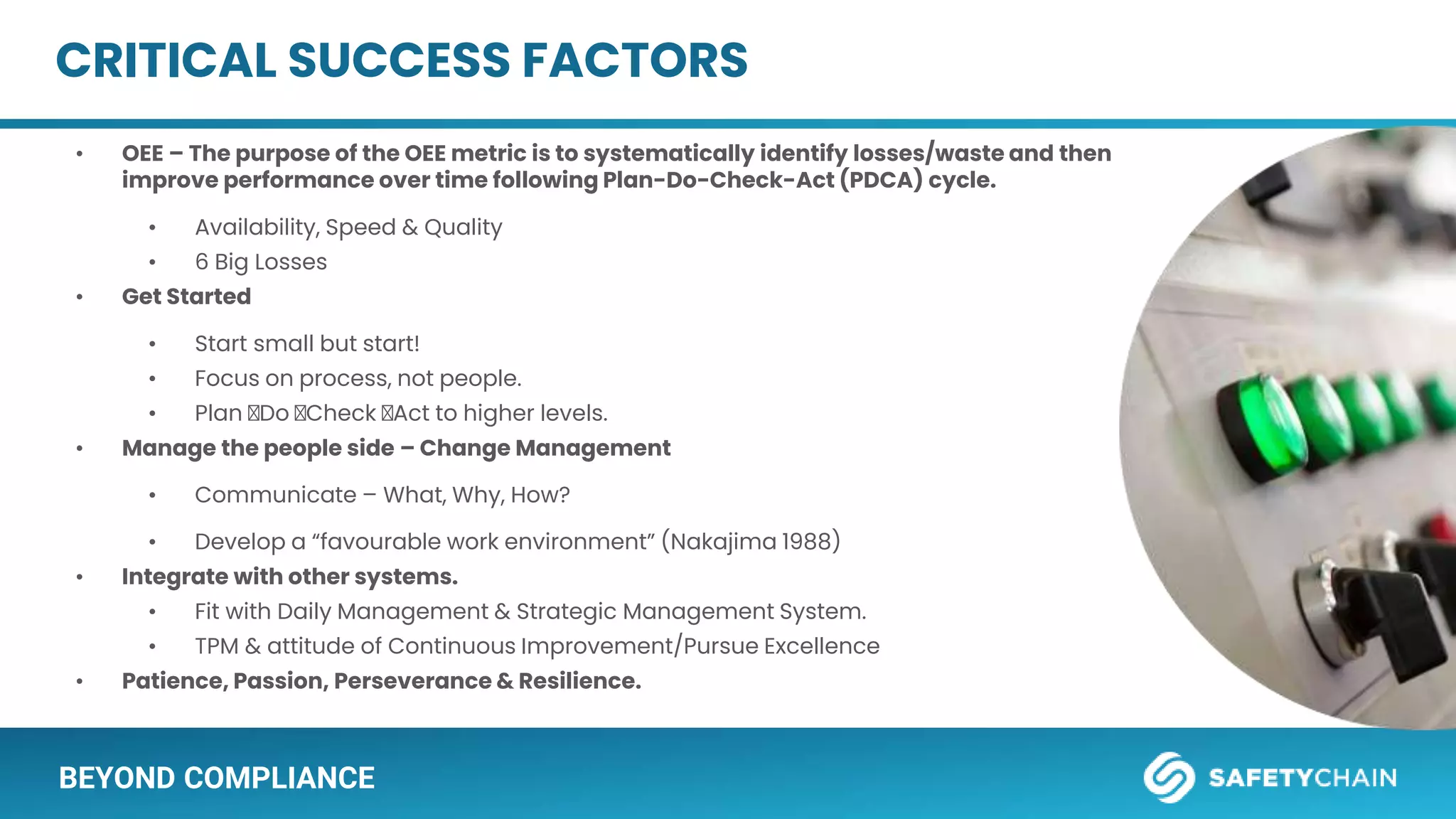

The document outlines a webinar and podcast series aimed at process manufacturers, led by Vern Campbell, focusing on leveraging Overall Equipment Effectiveness (OEE) to enhance performance and minimize downtime. It details the objectives, agenda, and key components of OEE, including its calculation, the six big losses that affect productivity, and strategies for effective implementation. The session emphasizes the importance of senior management commitment and a continuous improvement mindset to successfully integrate OEE into operational practices.