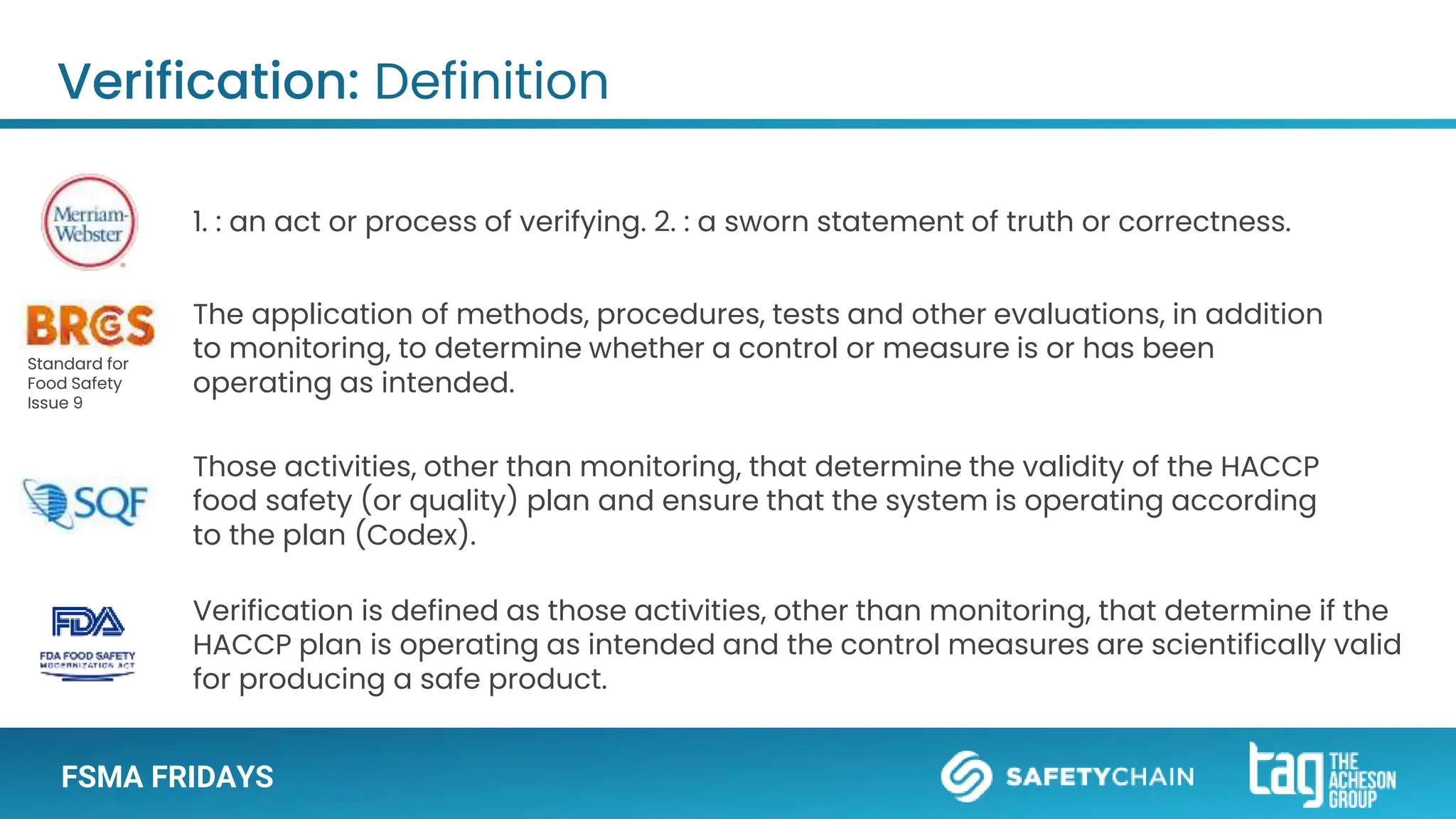

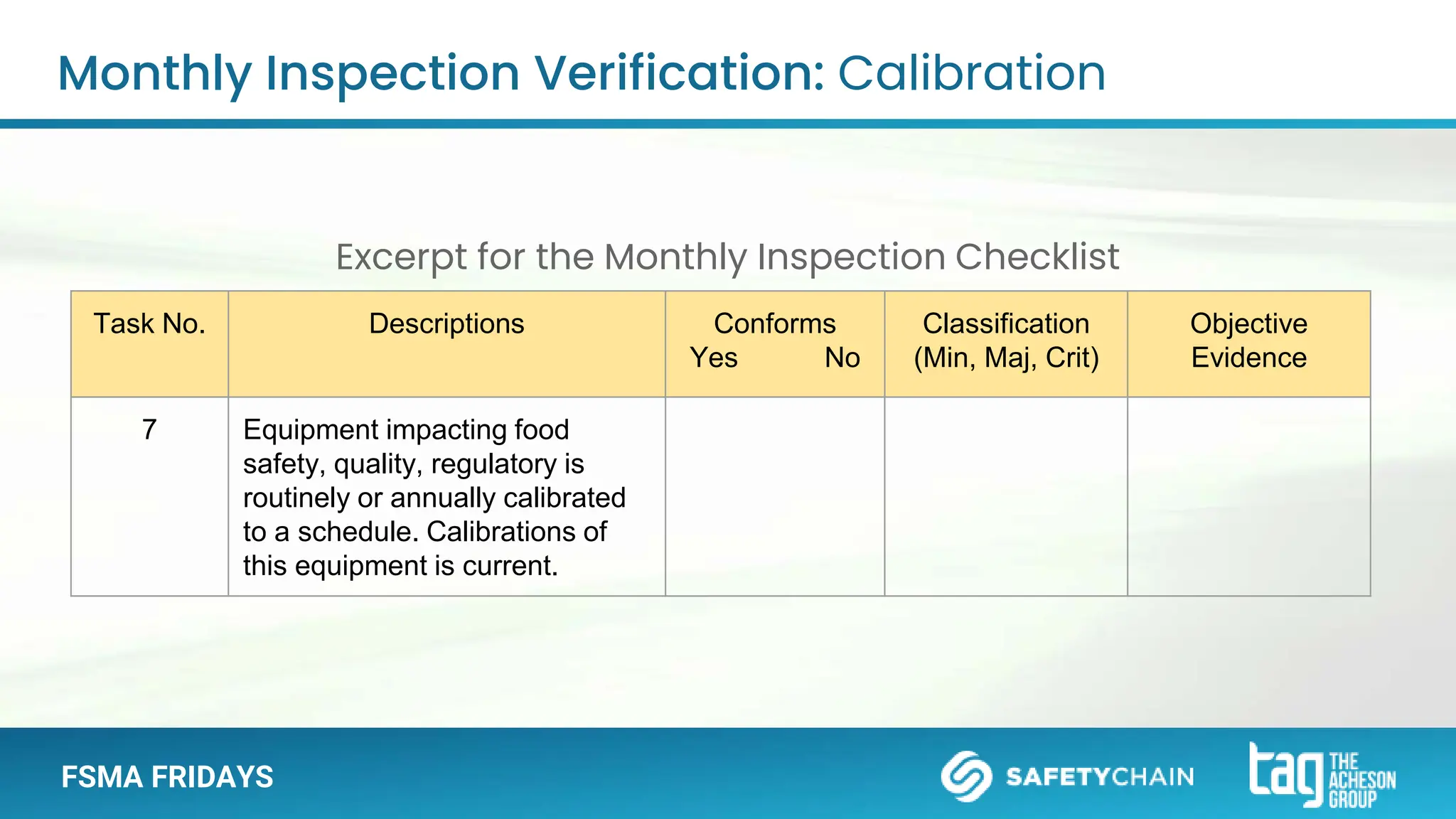

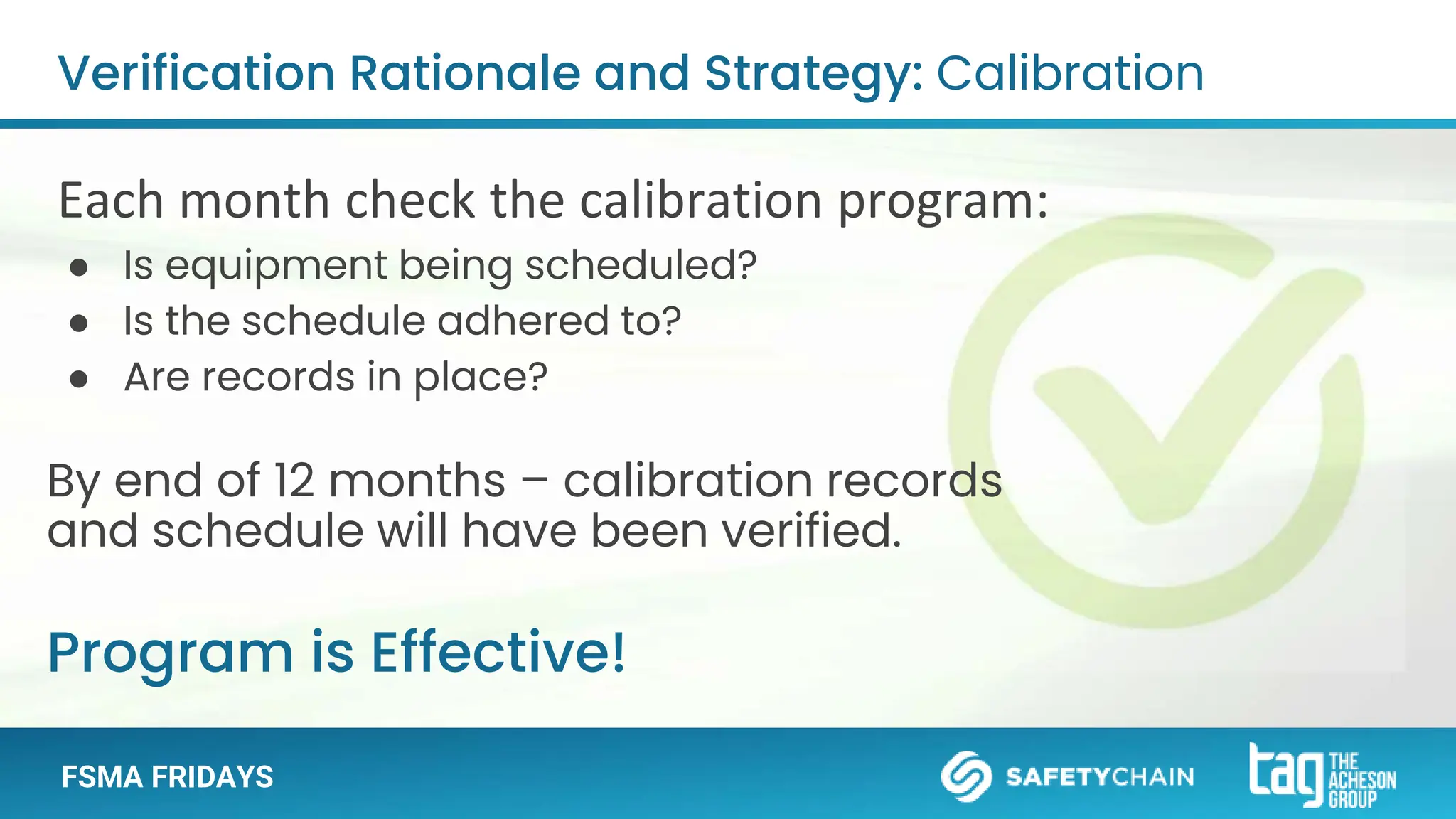

The document discusses the FSMA Fridays webinar series, which provides updates and industry insights for food safety in the food, beverage, and CPG sectors. Key topics include regulatory updates, such as new FDA menu labeling guidance and a salmonella outbreak, along with a structured approach to monthly inspections for verifying food safety and hygiene practices. It outlines various verification tasks related to calibration, pest control, sanitation, and security to ensure compliance with food safety standards.

![FSMA FRIDAYS

FSMA FRIDAYS

FSMA: Regulatory Updates

● FDA Released New Menu Labeling Guidance:

(source: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/draft-guidance-industry-menu-labeling-supplemental-guidance-edition-2 )

This guidance document addresses stakeholder questions regarding the implementation of nutrition labeling required

for foods sold in covered establishments,[1] including examples of alternatives to aid in compliance

● Salmonella outbreak associated with cantaloupe:

(source: https://www.cdc.gov/salmonella/sundsvall-11-23/index.html)

○ Last recall announced on Dec 6th – First recall was 11/9/23. The Traceability Rule may help with identifying

potentially contaminated product in the supply chain

○ This Salmonella serotype, Sundsvall, appears to have a very high hospitalization rate of about

42% in the US with 34% hospitalized in Canada](https://image.slidesharecdn.com/fsmafridaydecember2023-usingmonthlyinspectionsasatoolforprerequisiteprogramverification-231215181806-b301ceb2/75/Using-Monthly-Inspections-as-a-Tool-for-Prerequisite-Program-Verification-4-2048.jpg)