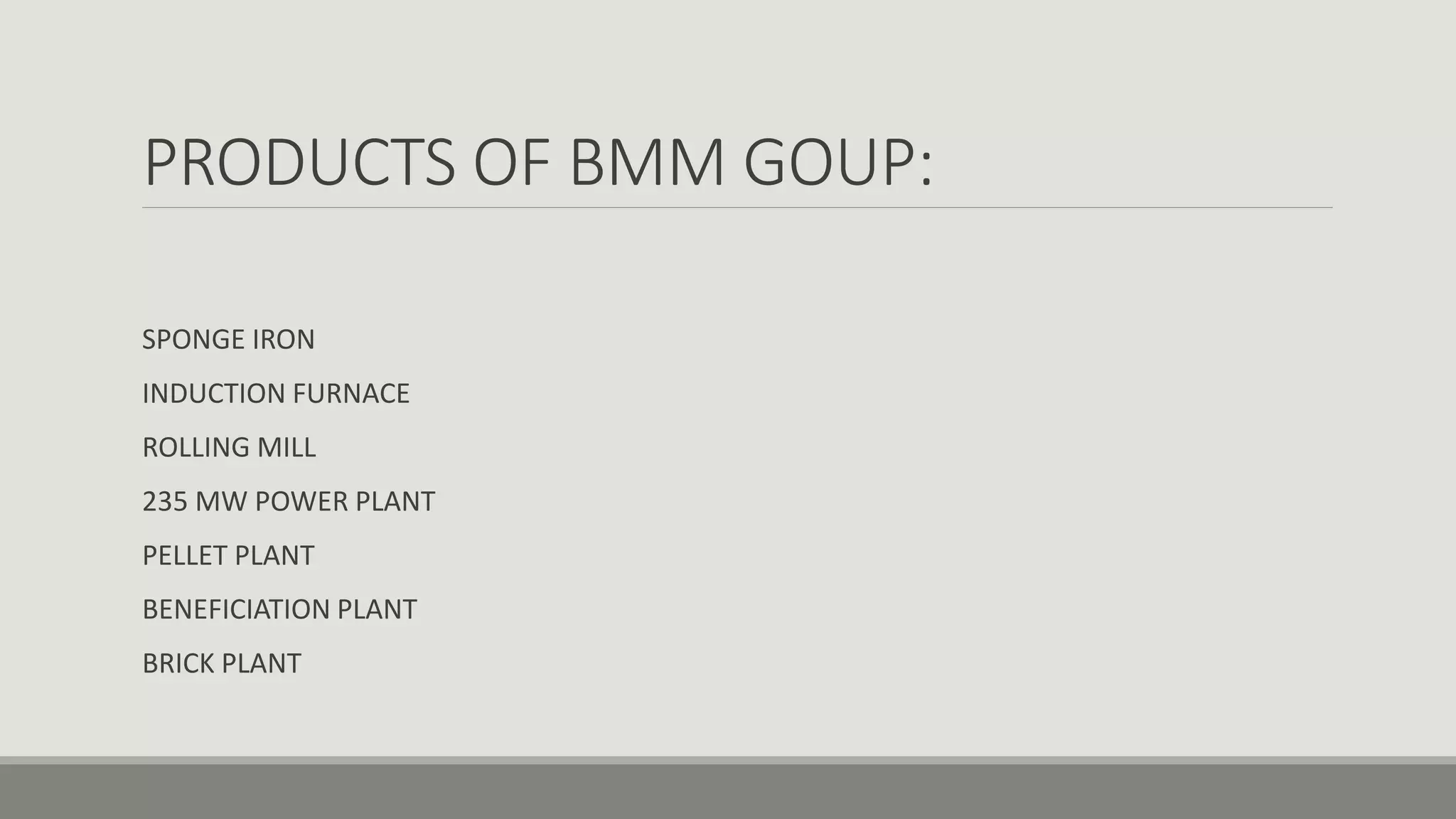

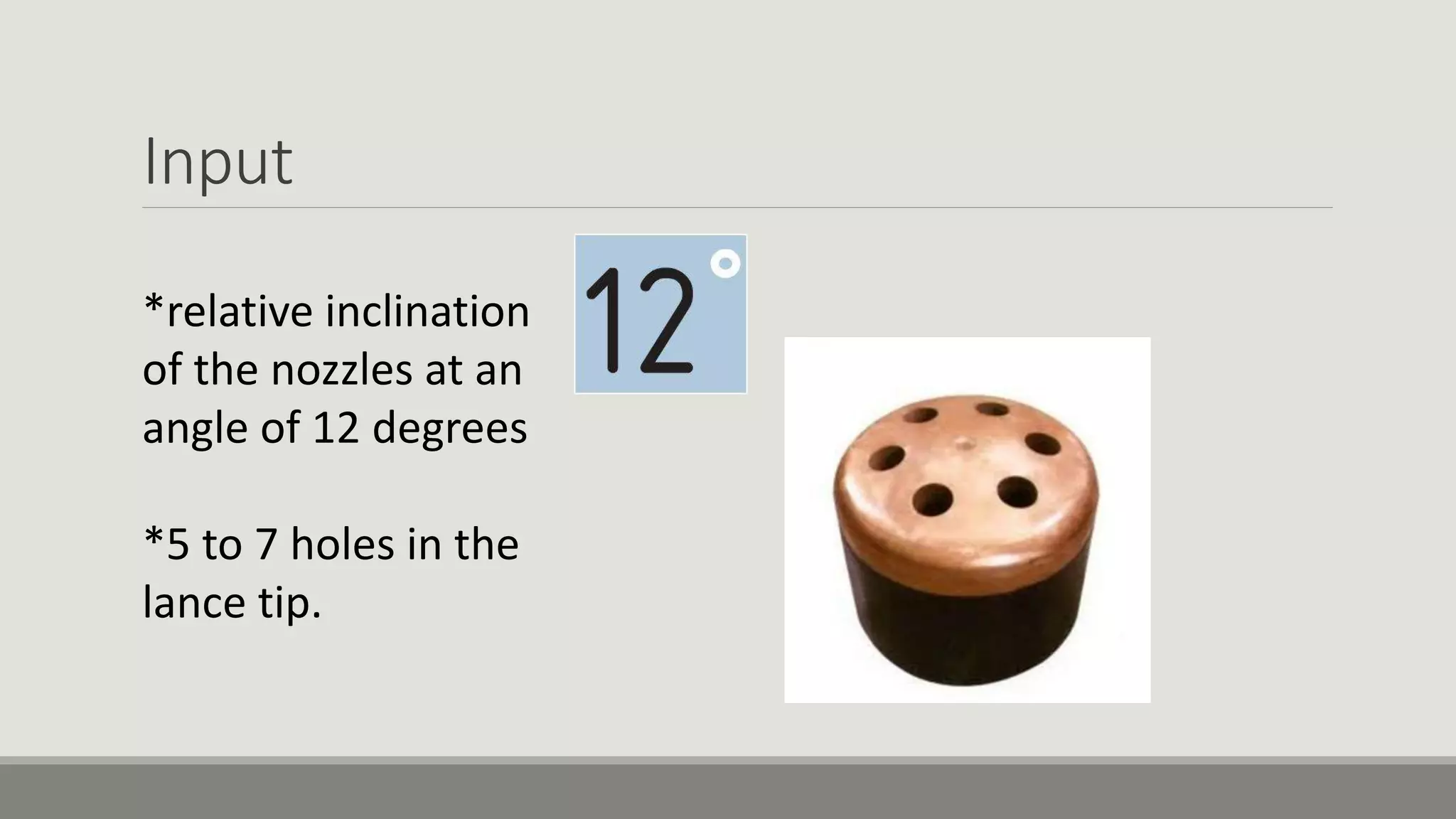

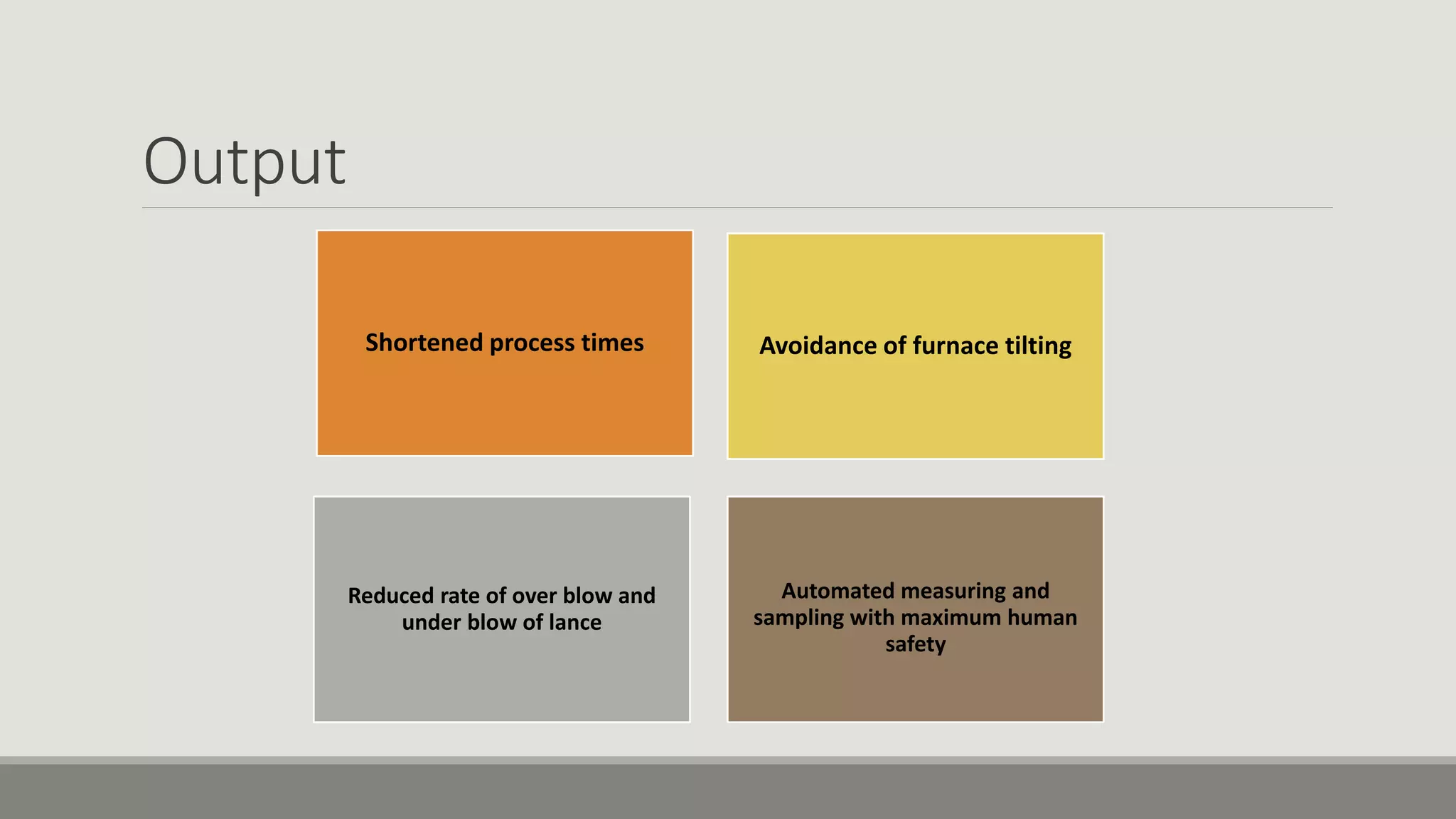

The document discusses the transformation process in businesses, detailing how inputs are converted into outputs, either goods or services. It includes a case study of BMM Ispat, highlighting their practices and challenges in modernizing operations, improving productivity, and ensuring compliance with environmental standards. Additionally, the document emphasizes the importance of maintaining good relationships with partners and addressing gaps in operational efficiency and environmental sustainability.