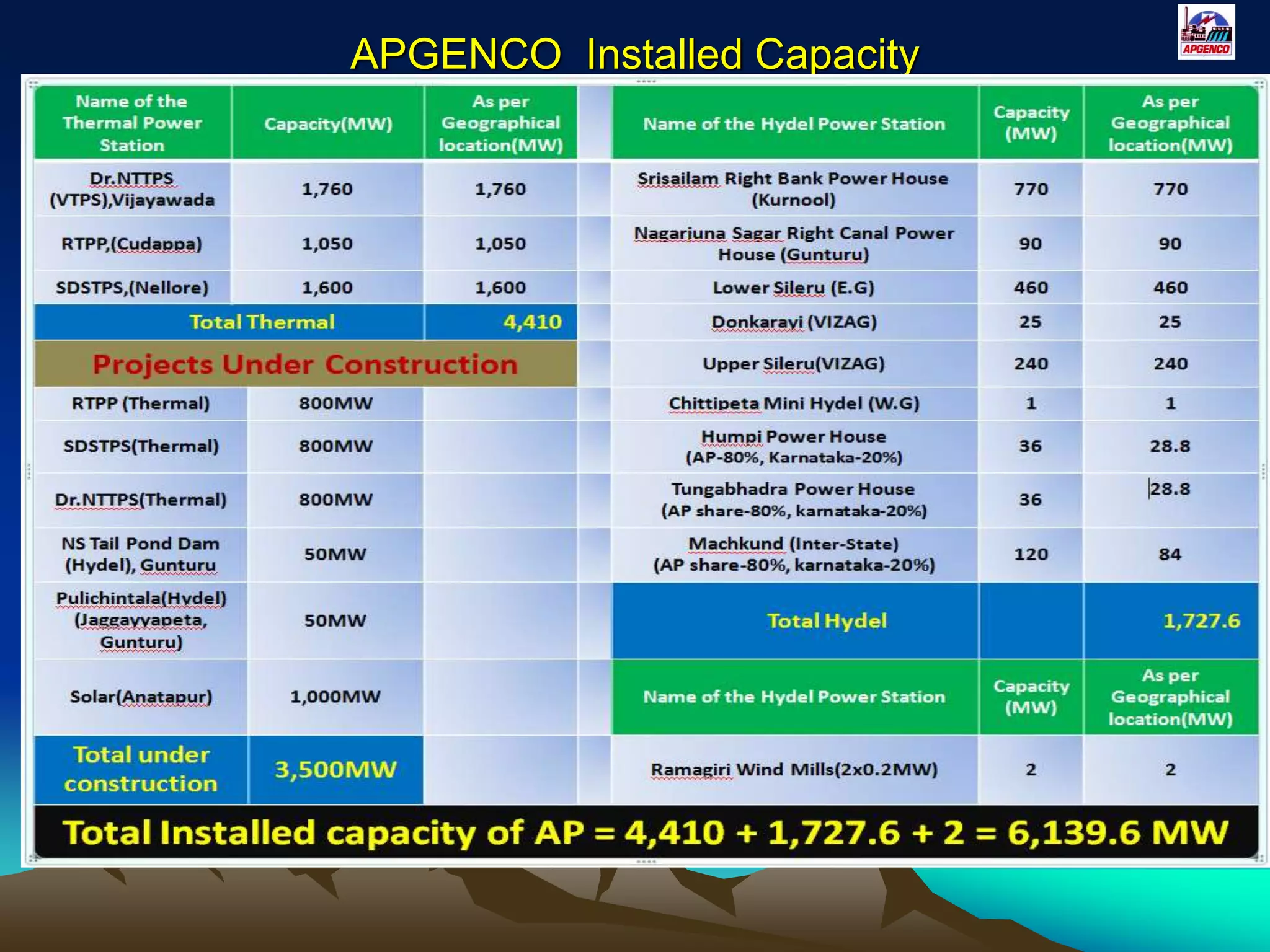

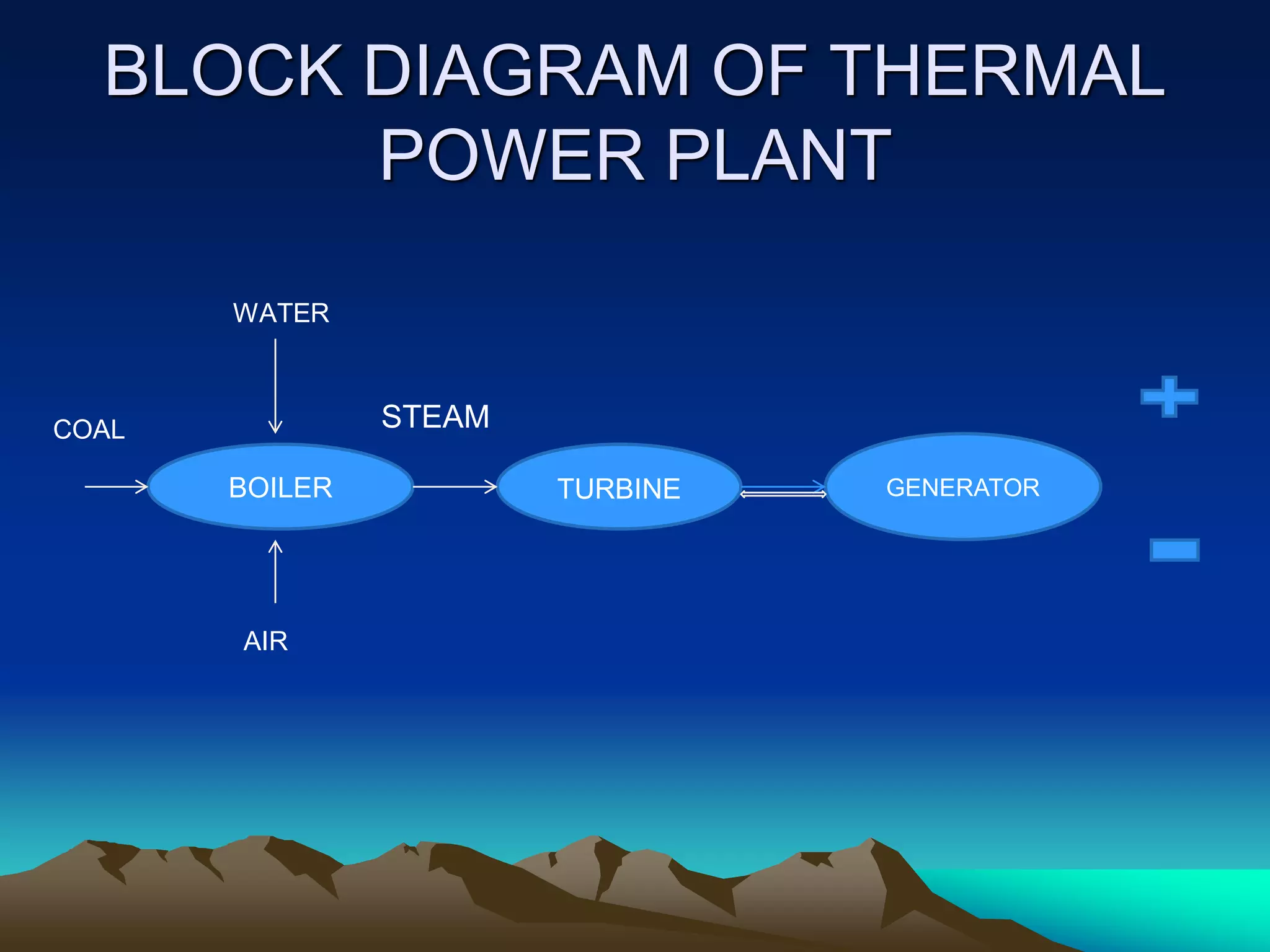

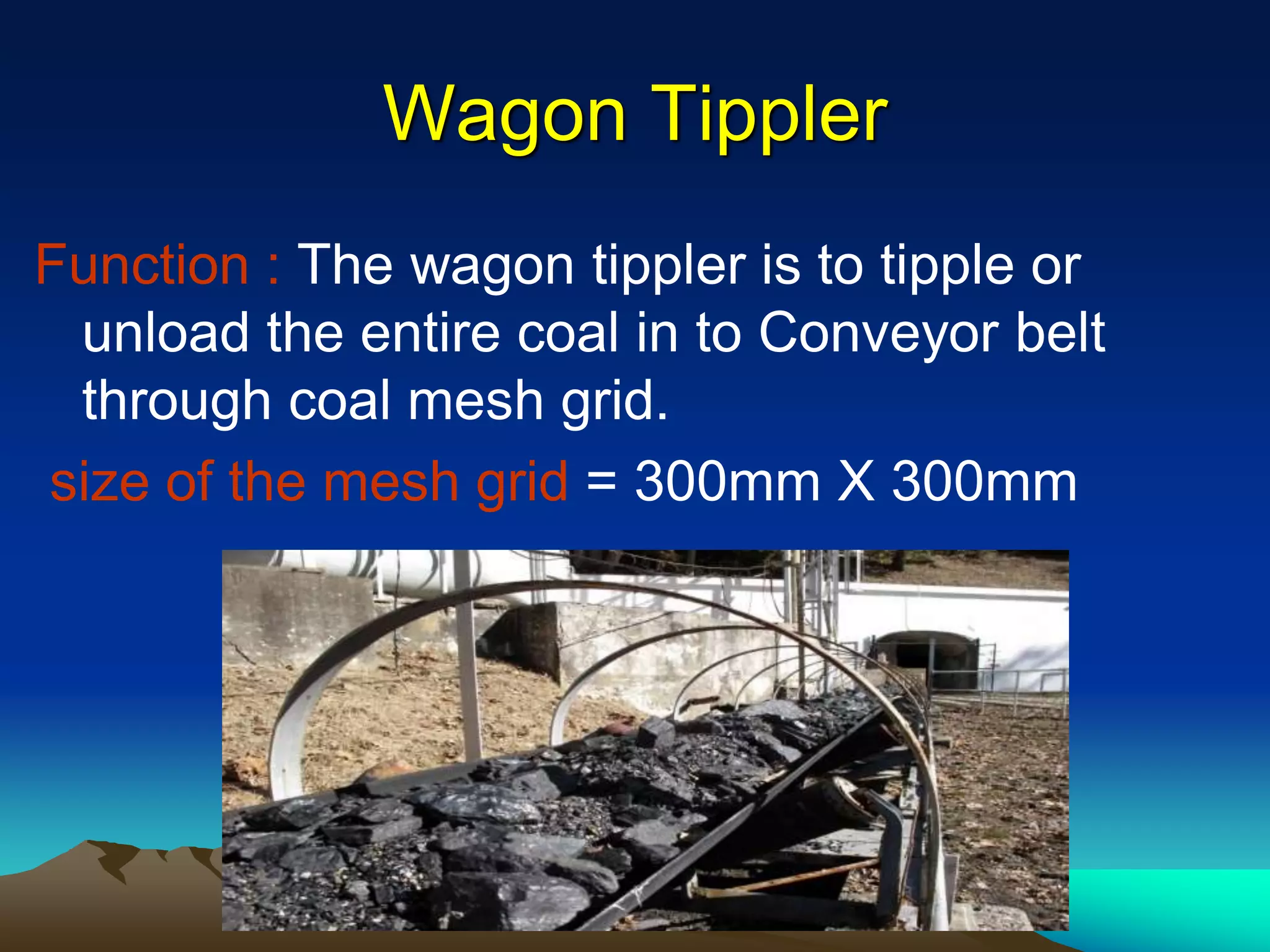

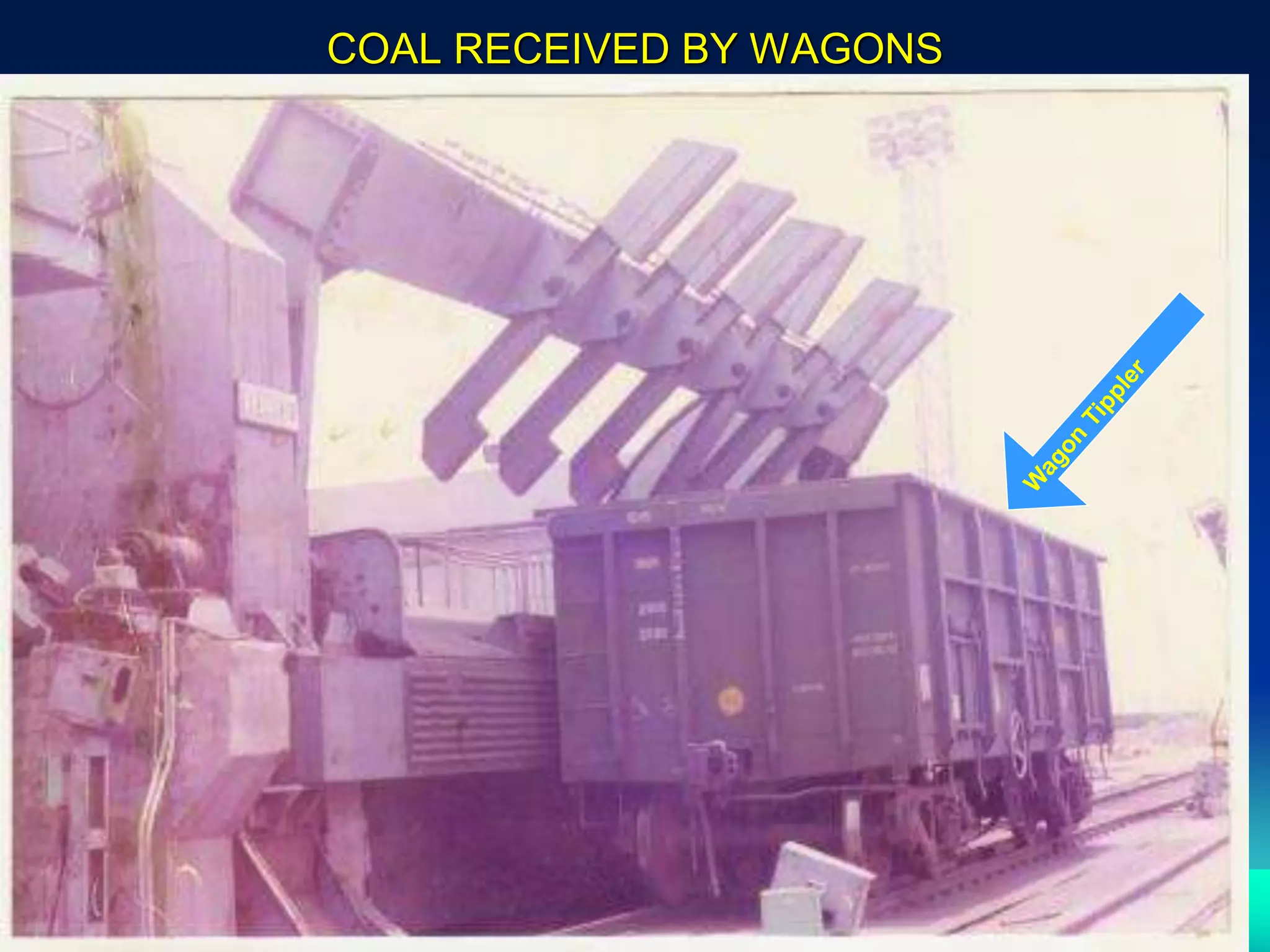

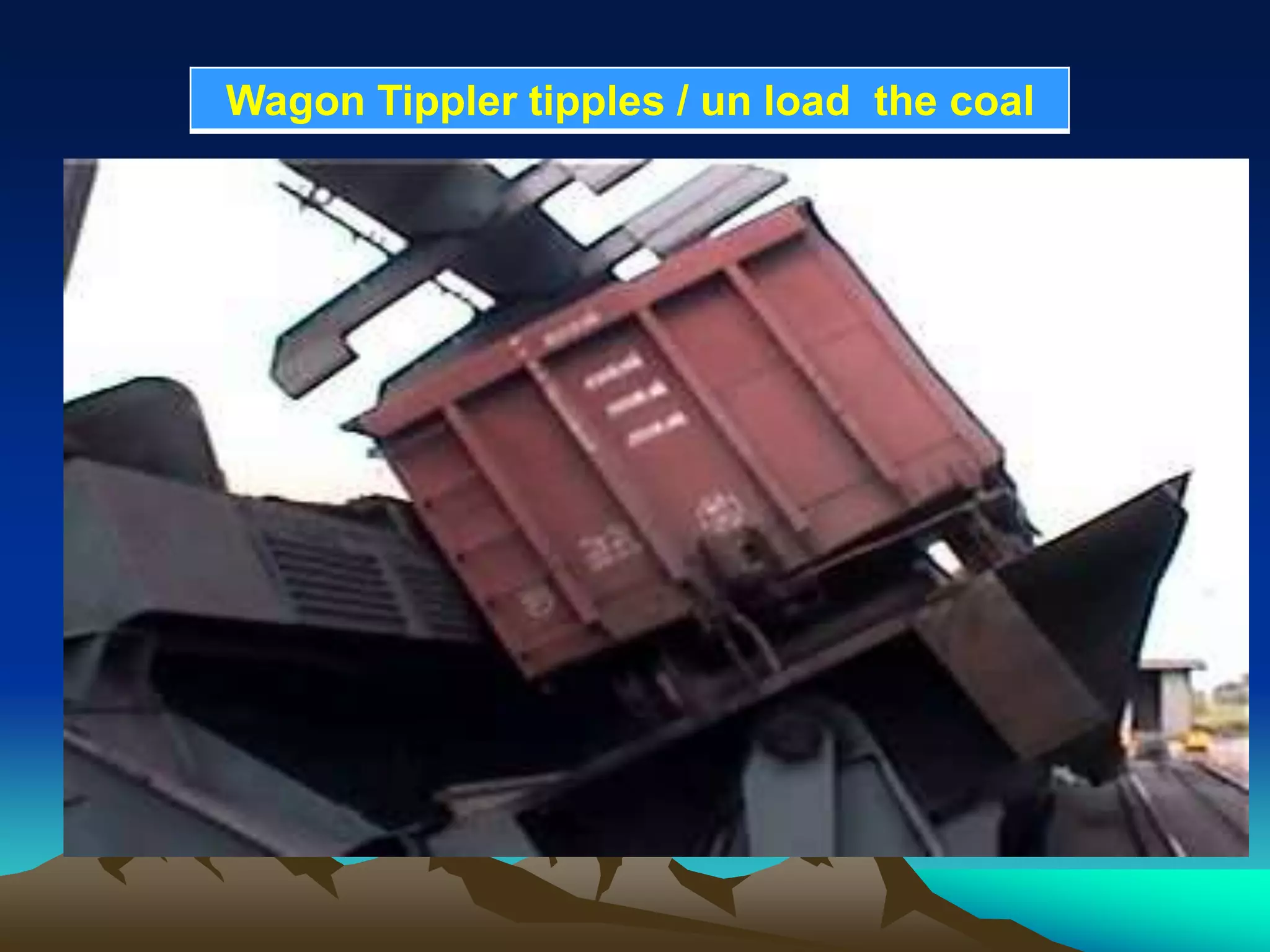

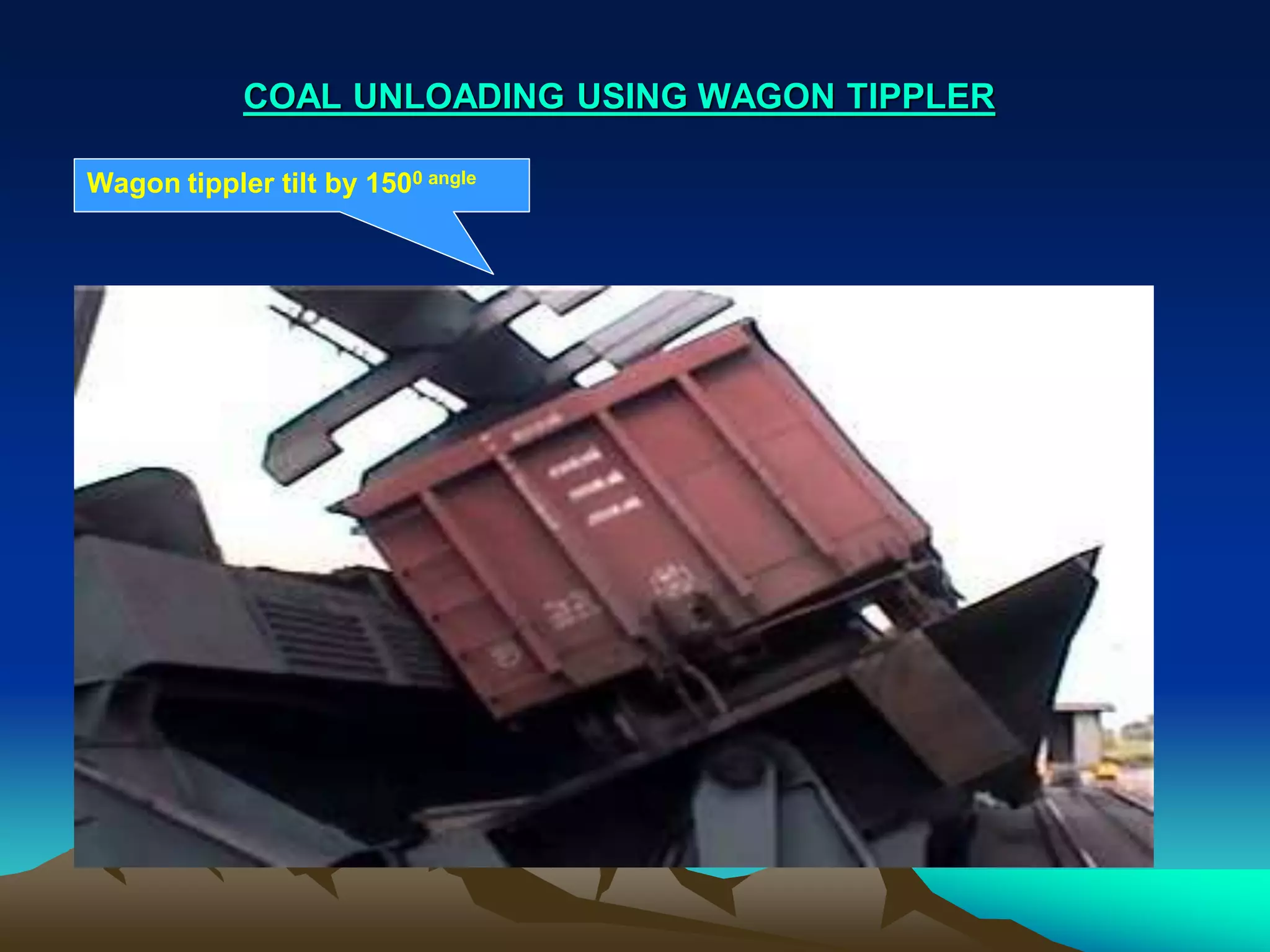

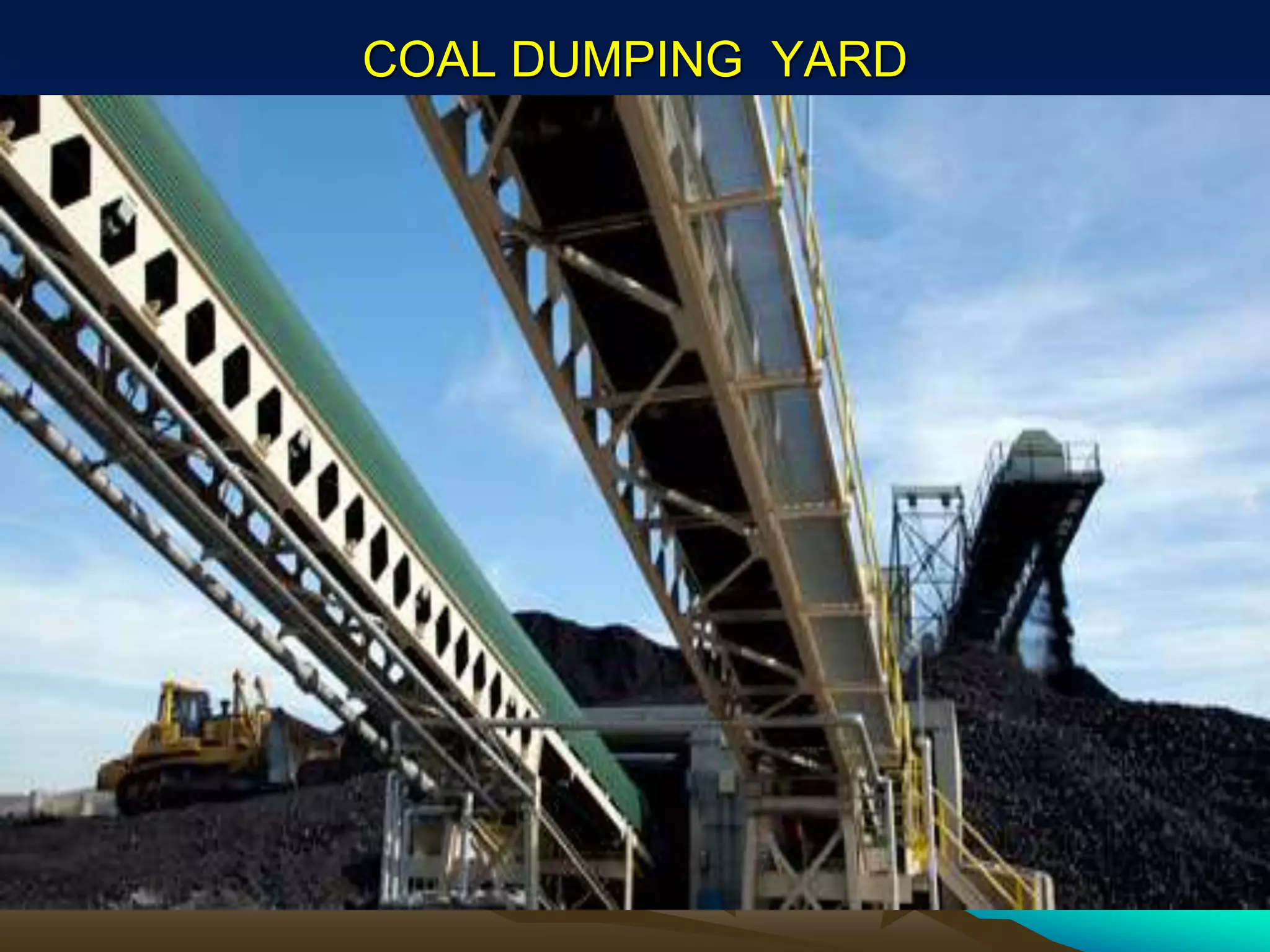

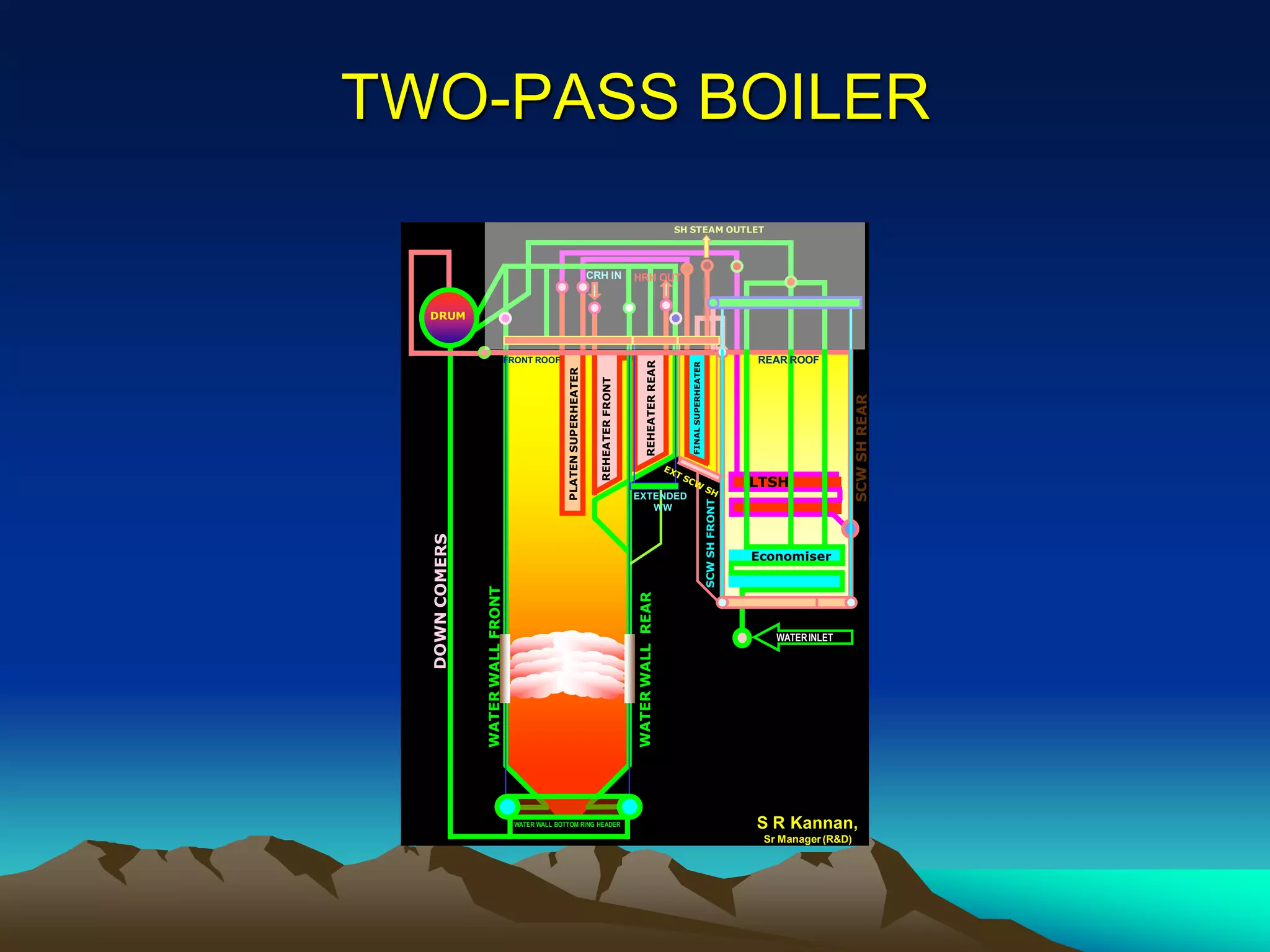

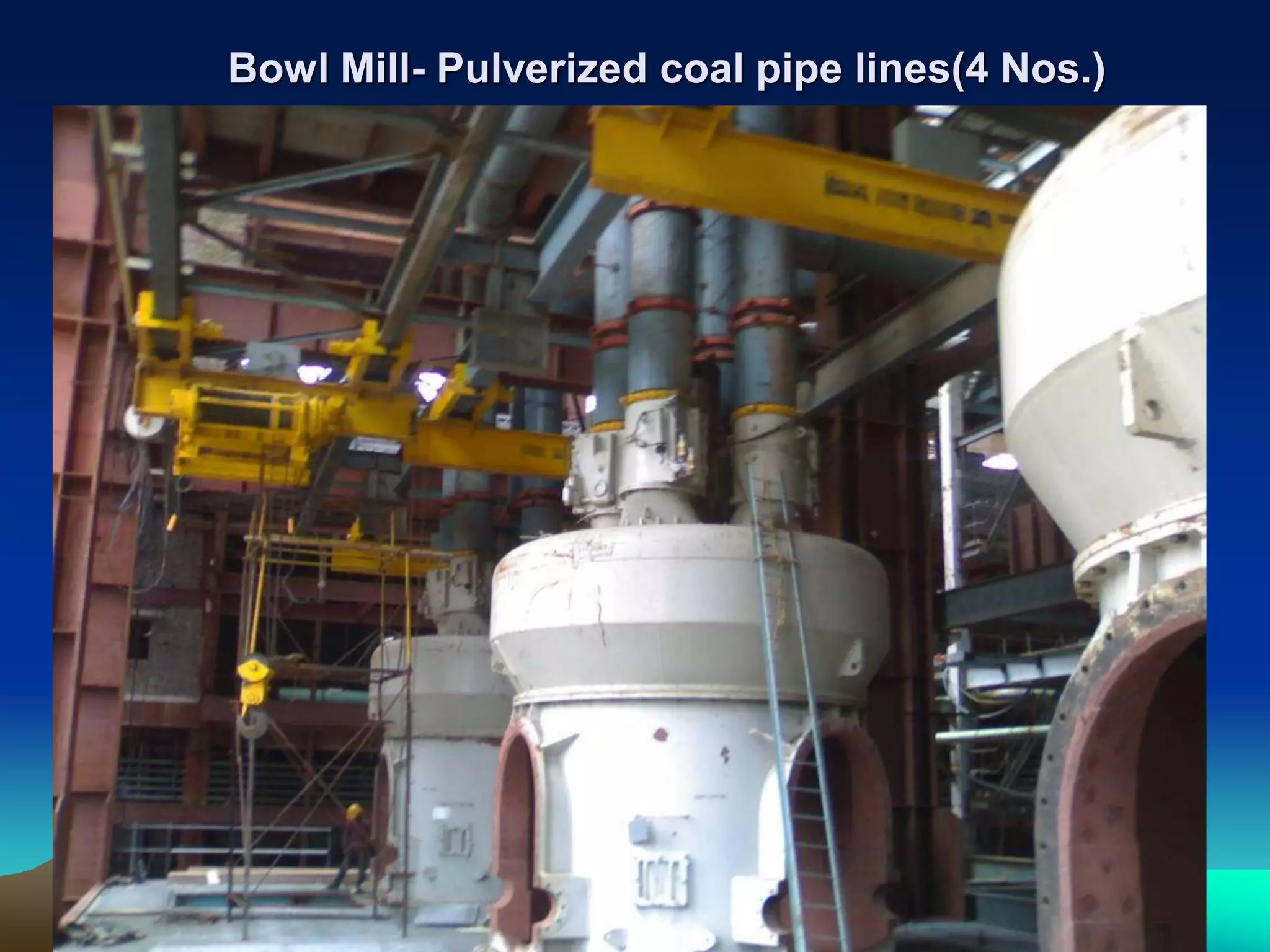

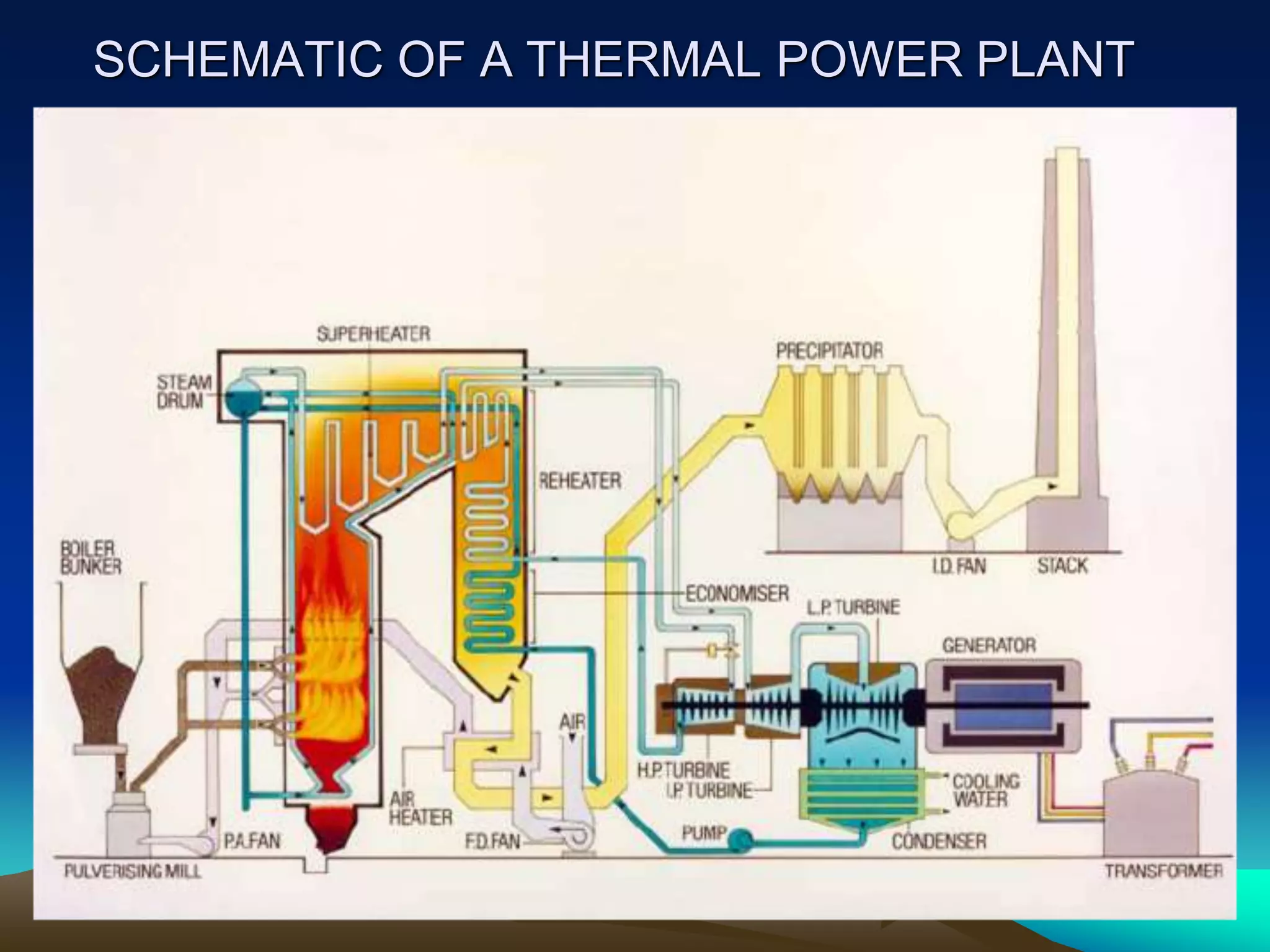

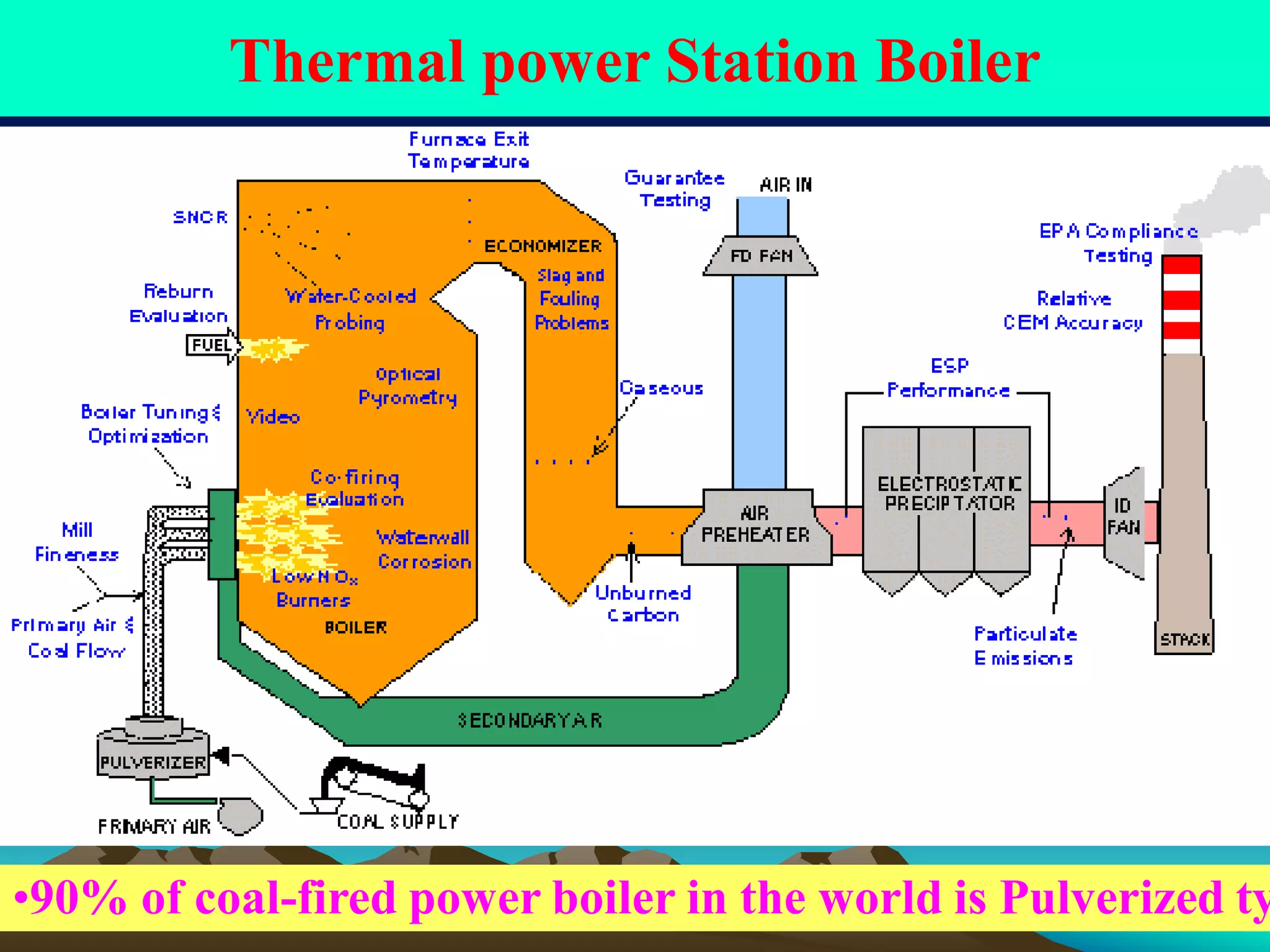

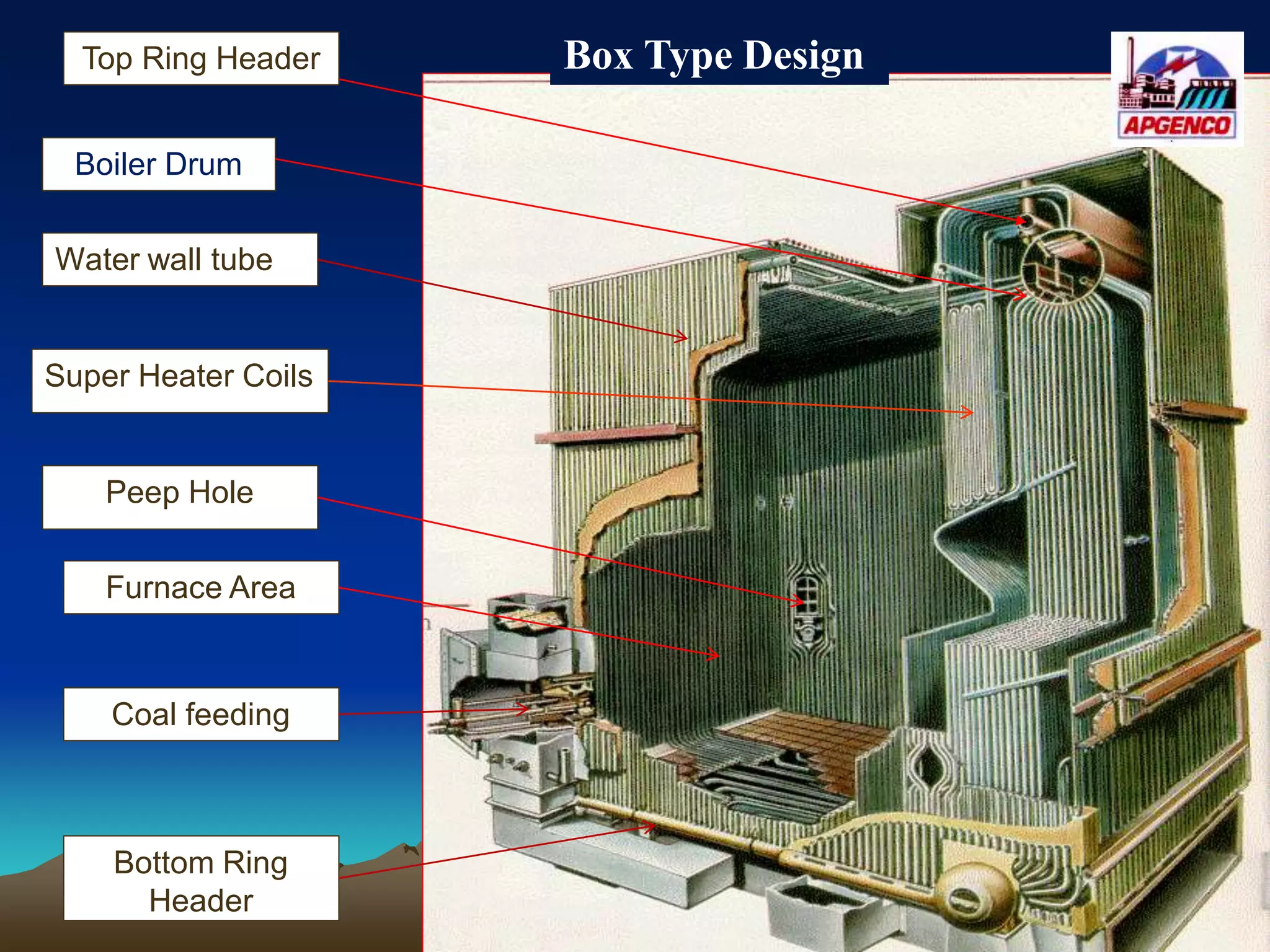

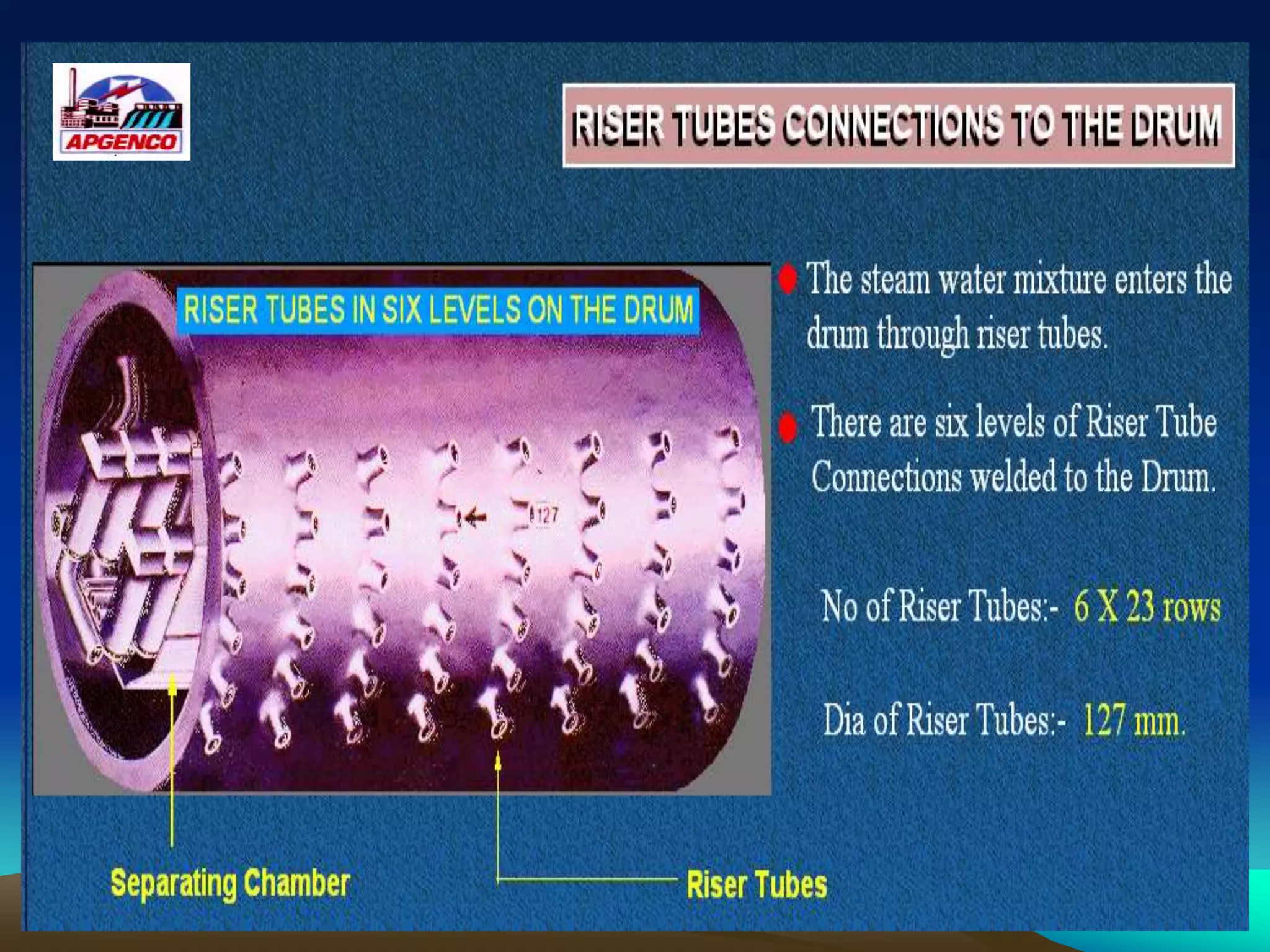

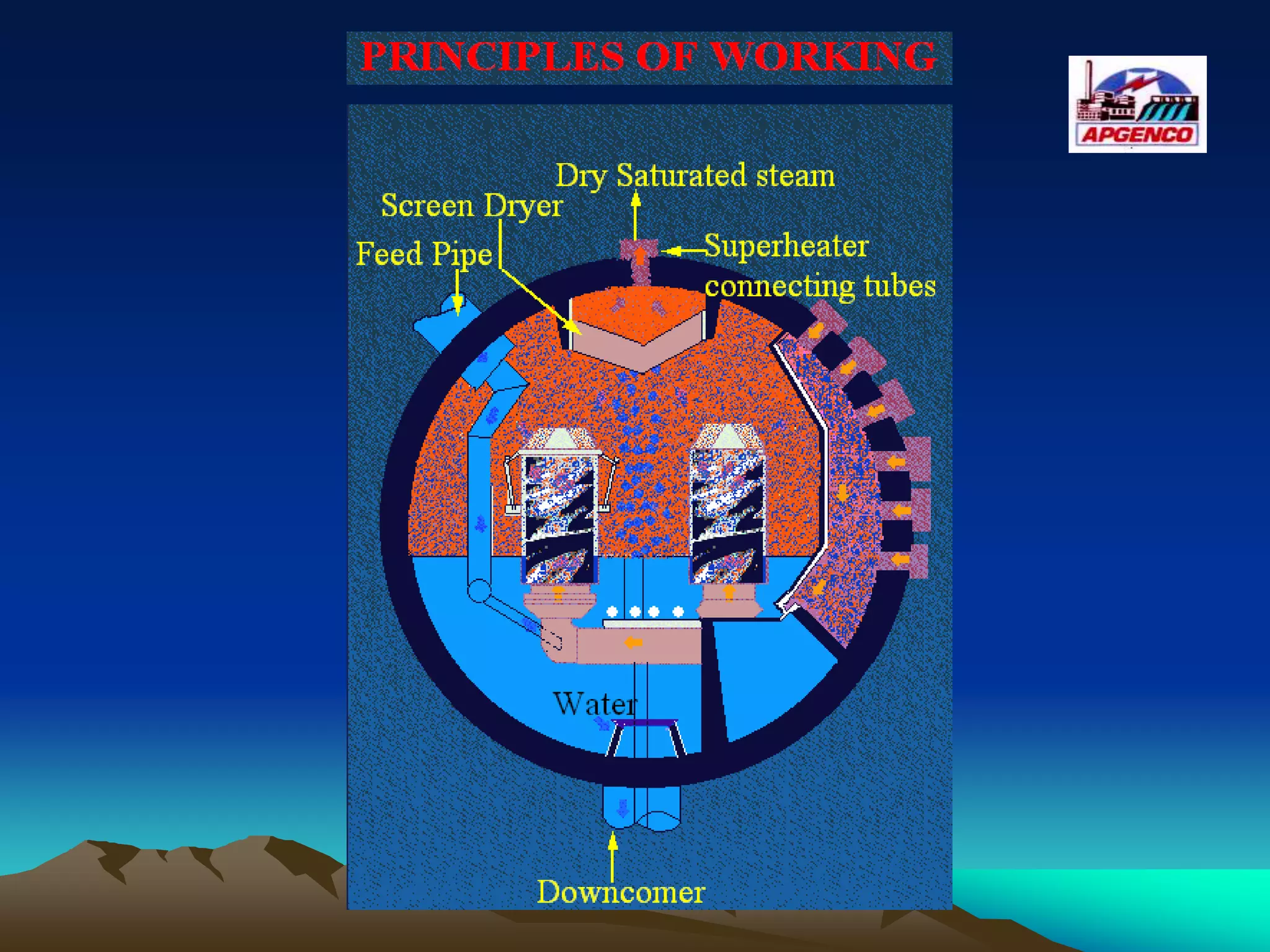

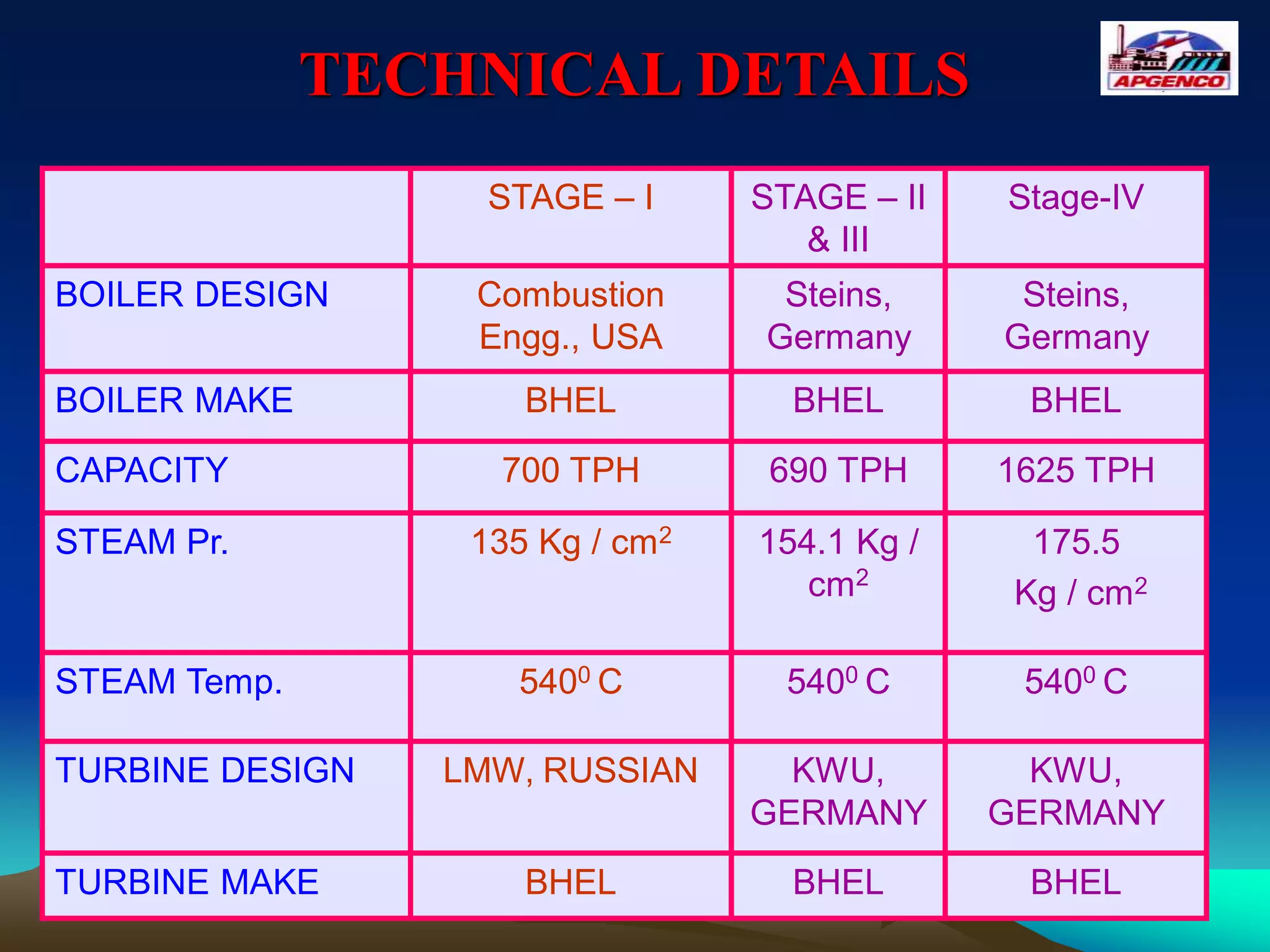

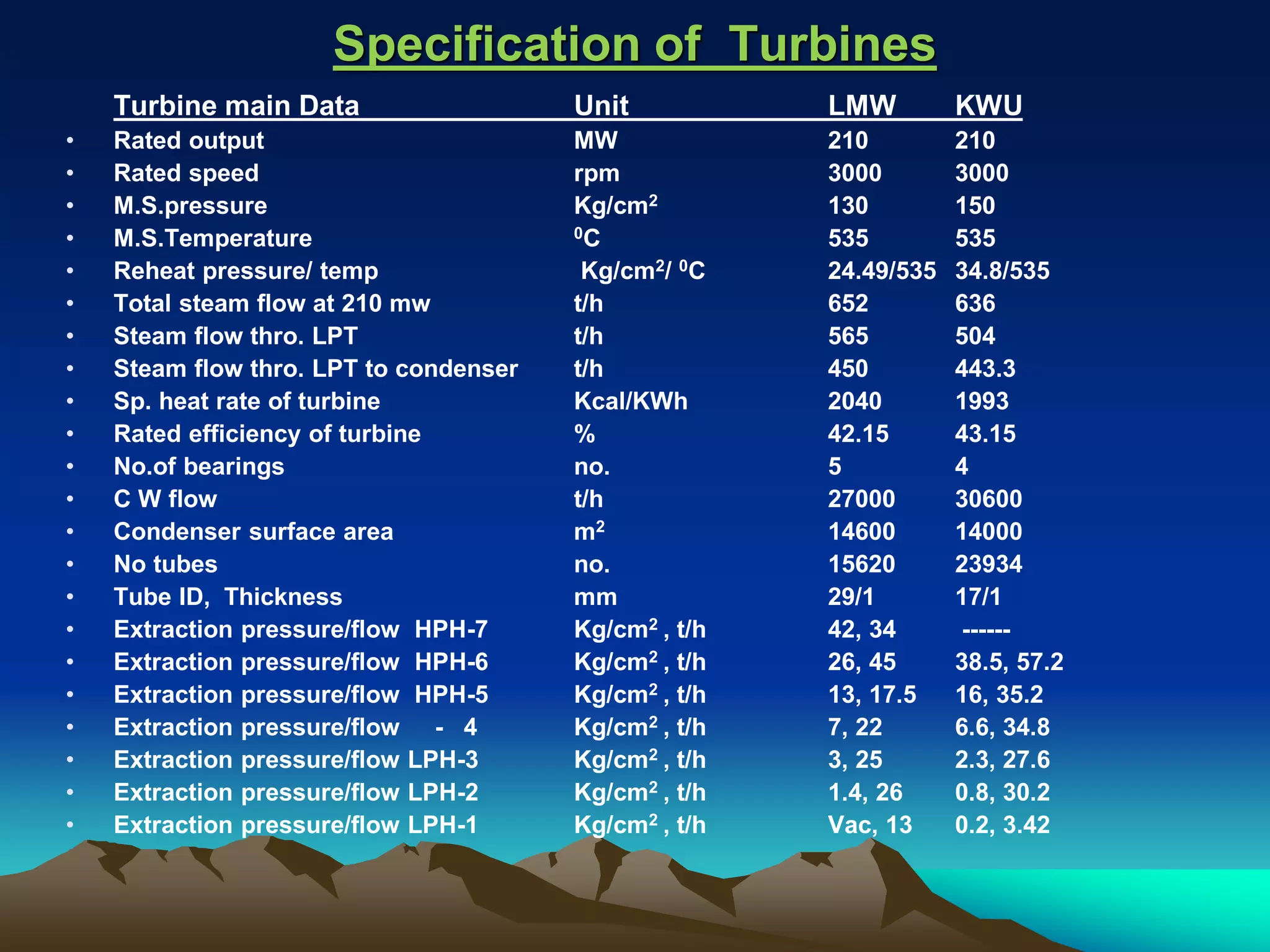

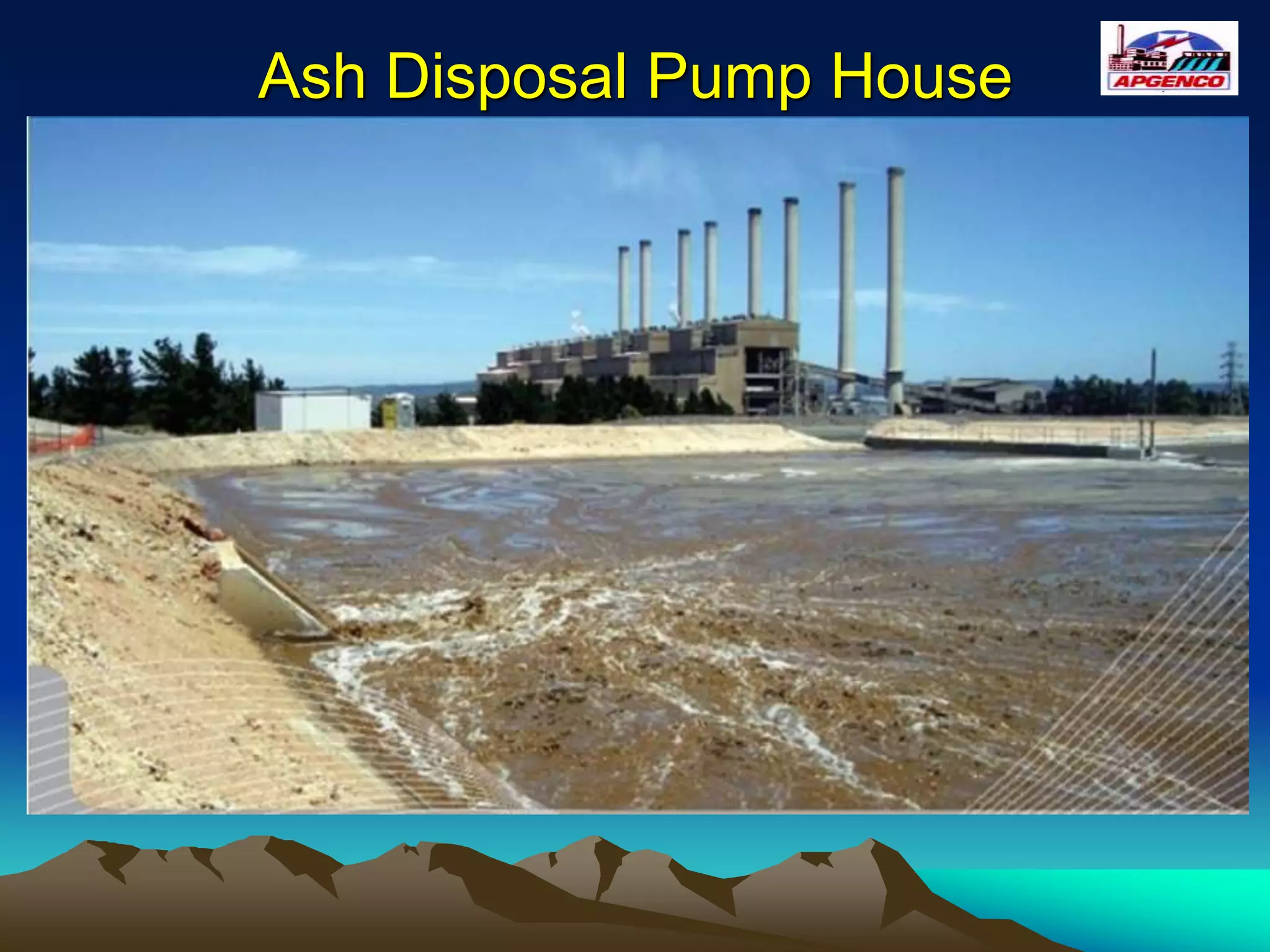

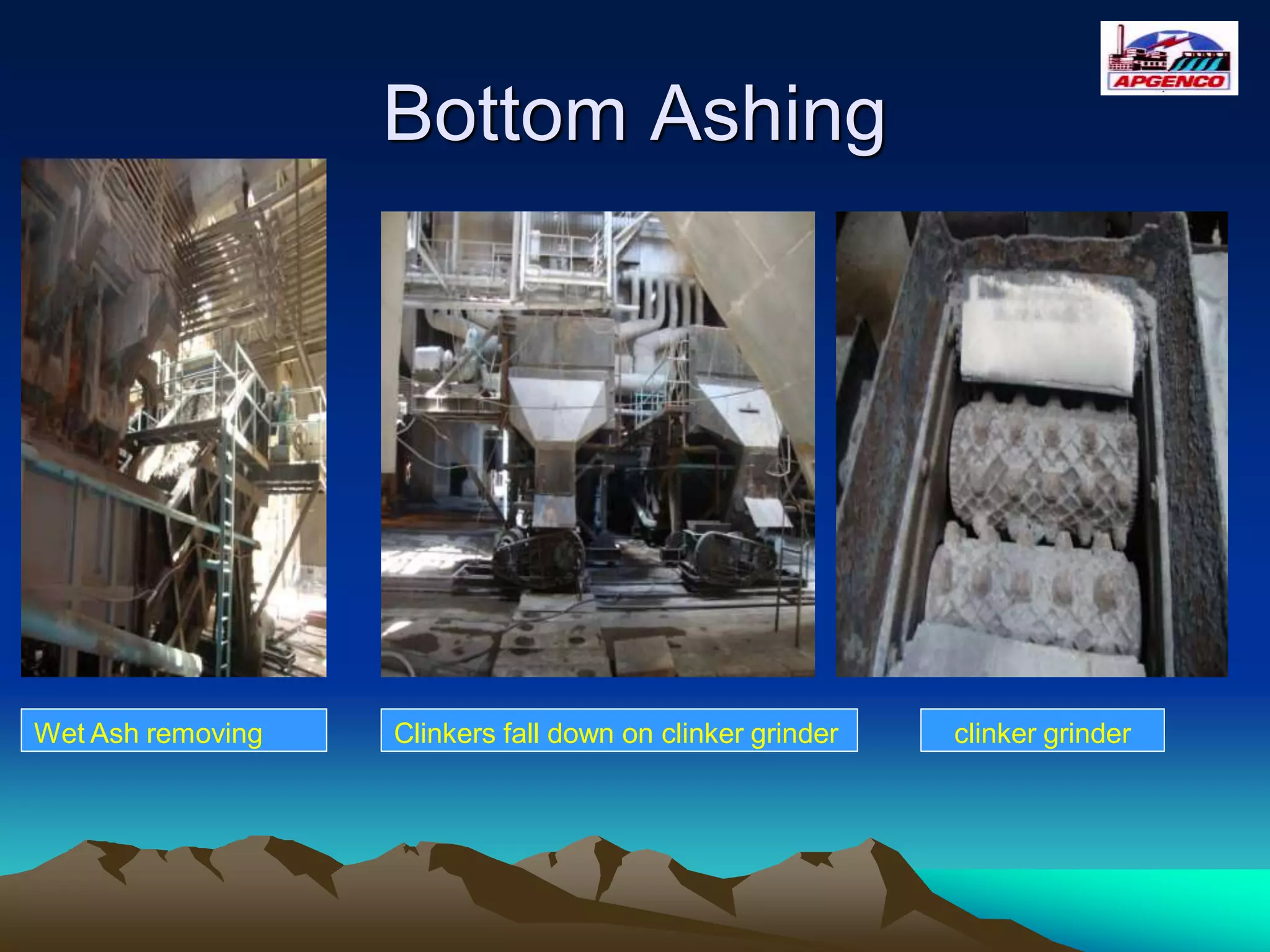

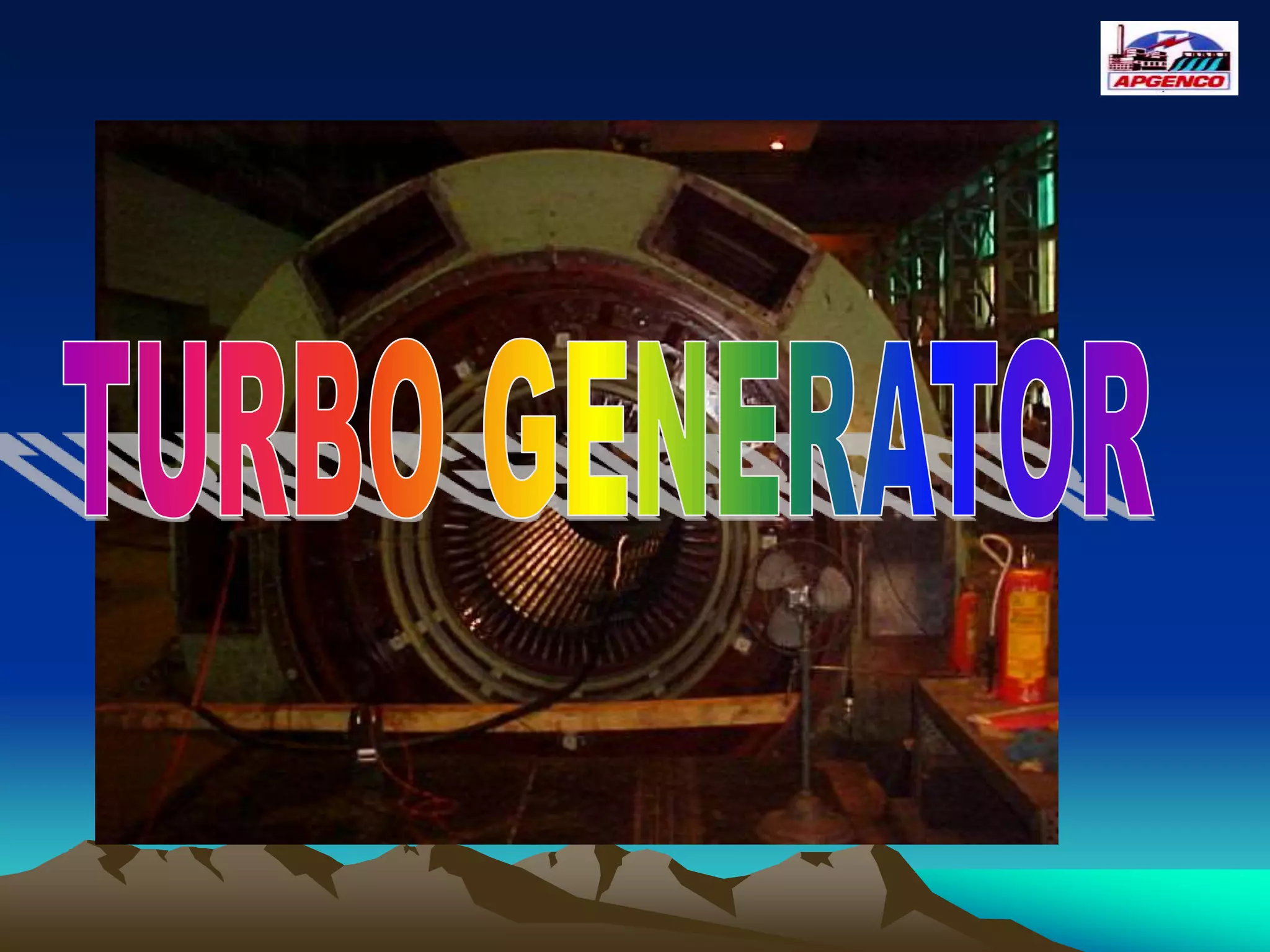

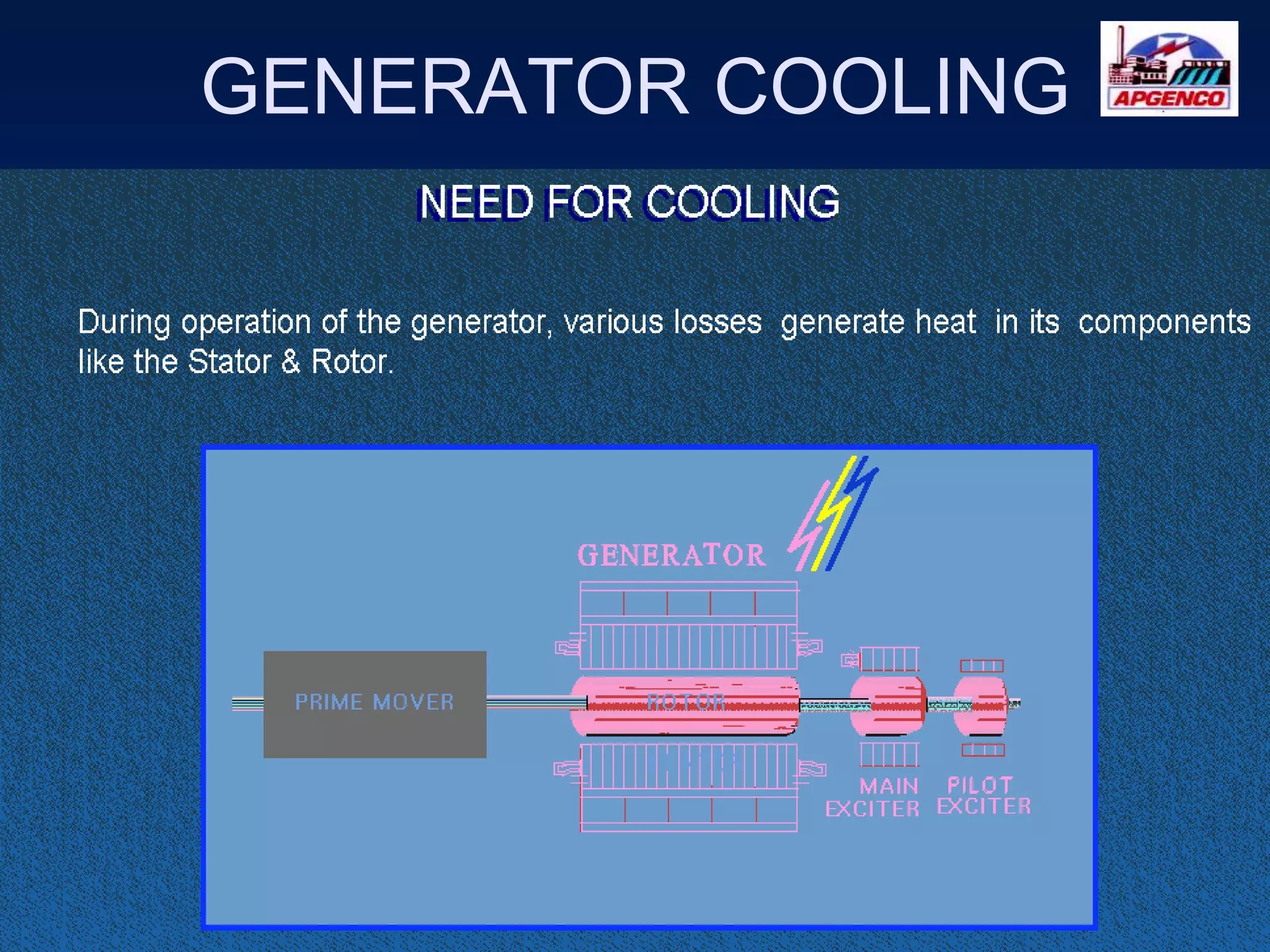

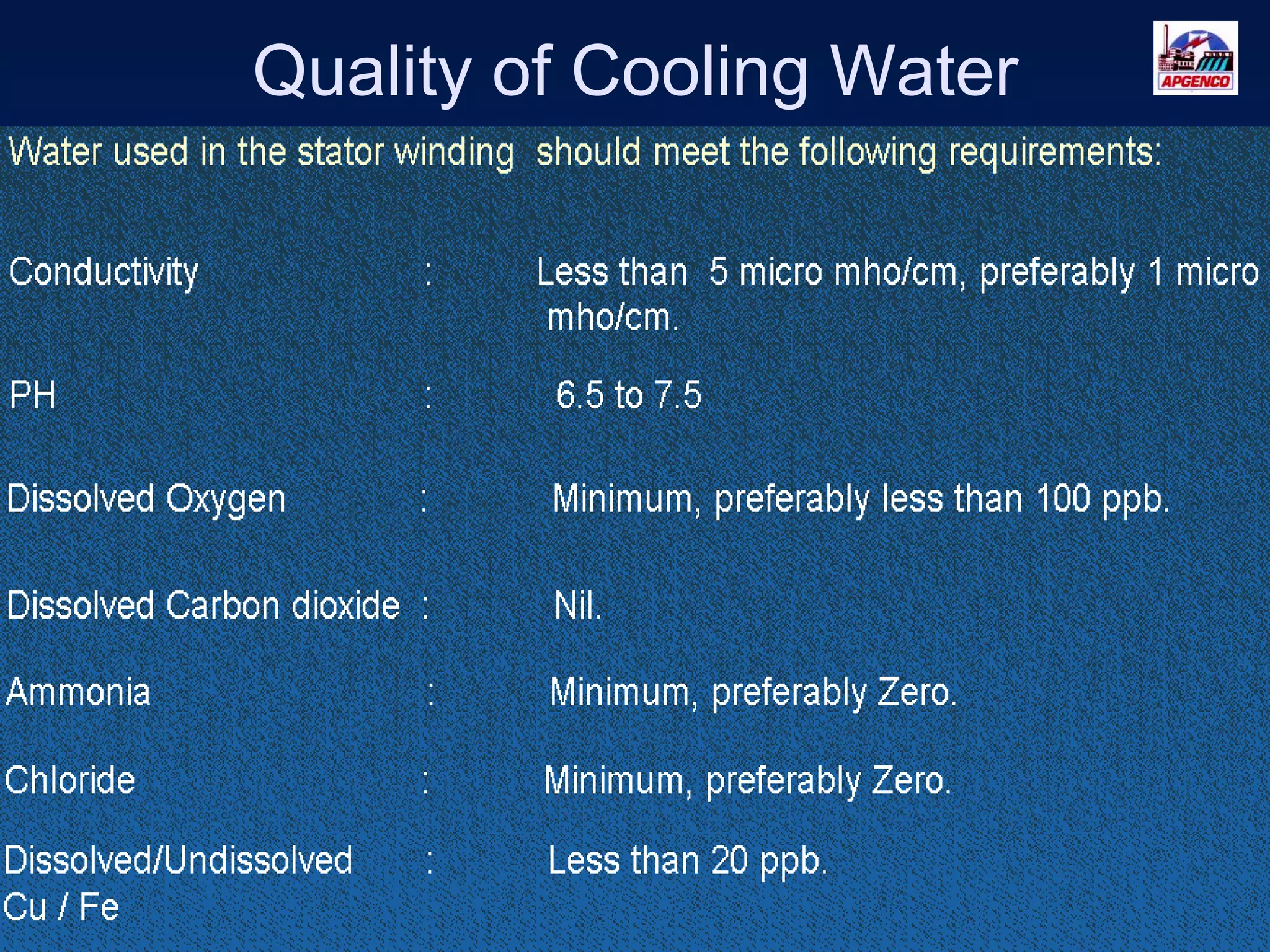

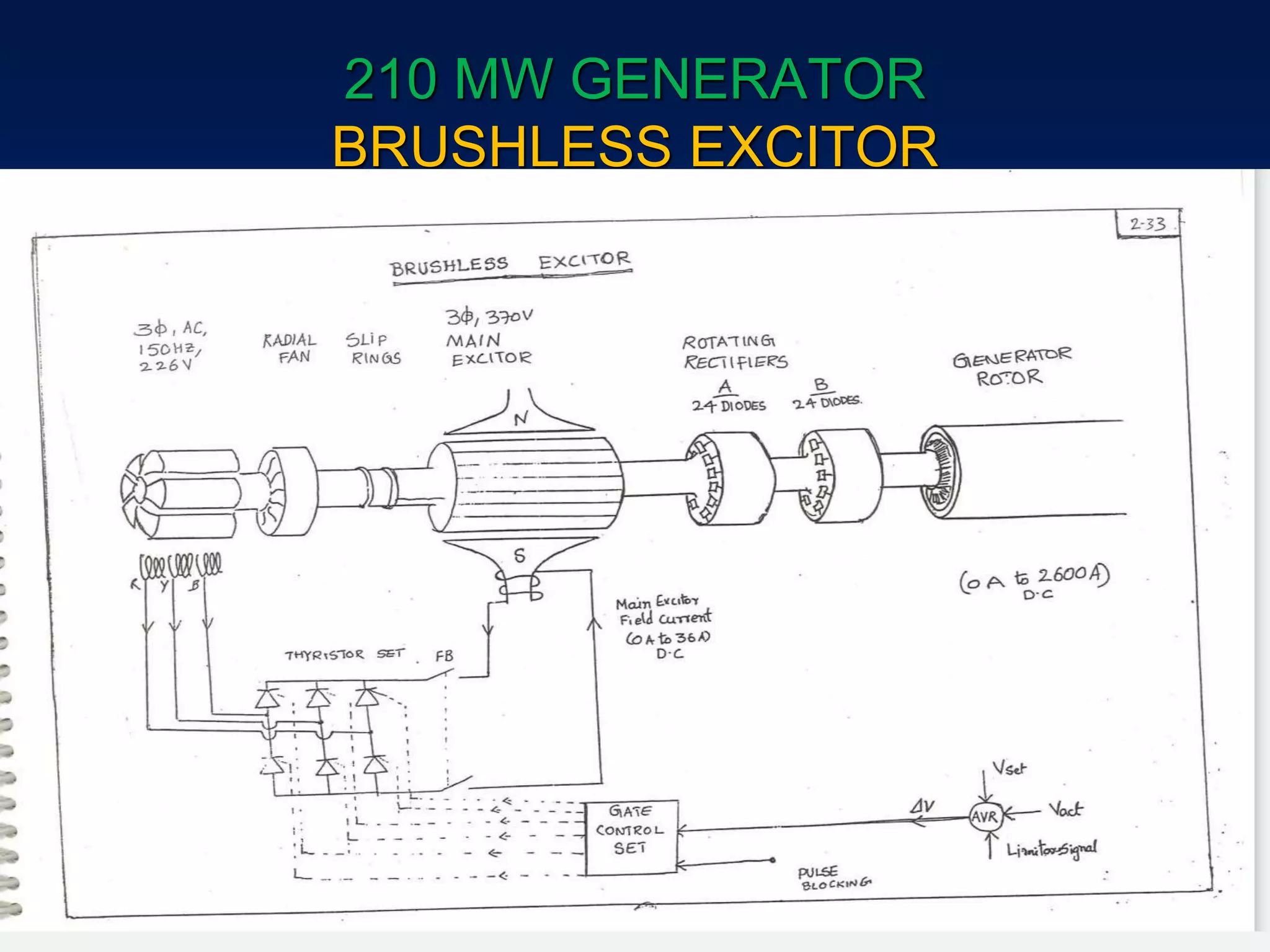

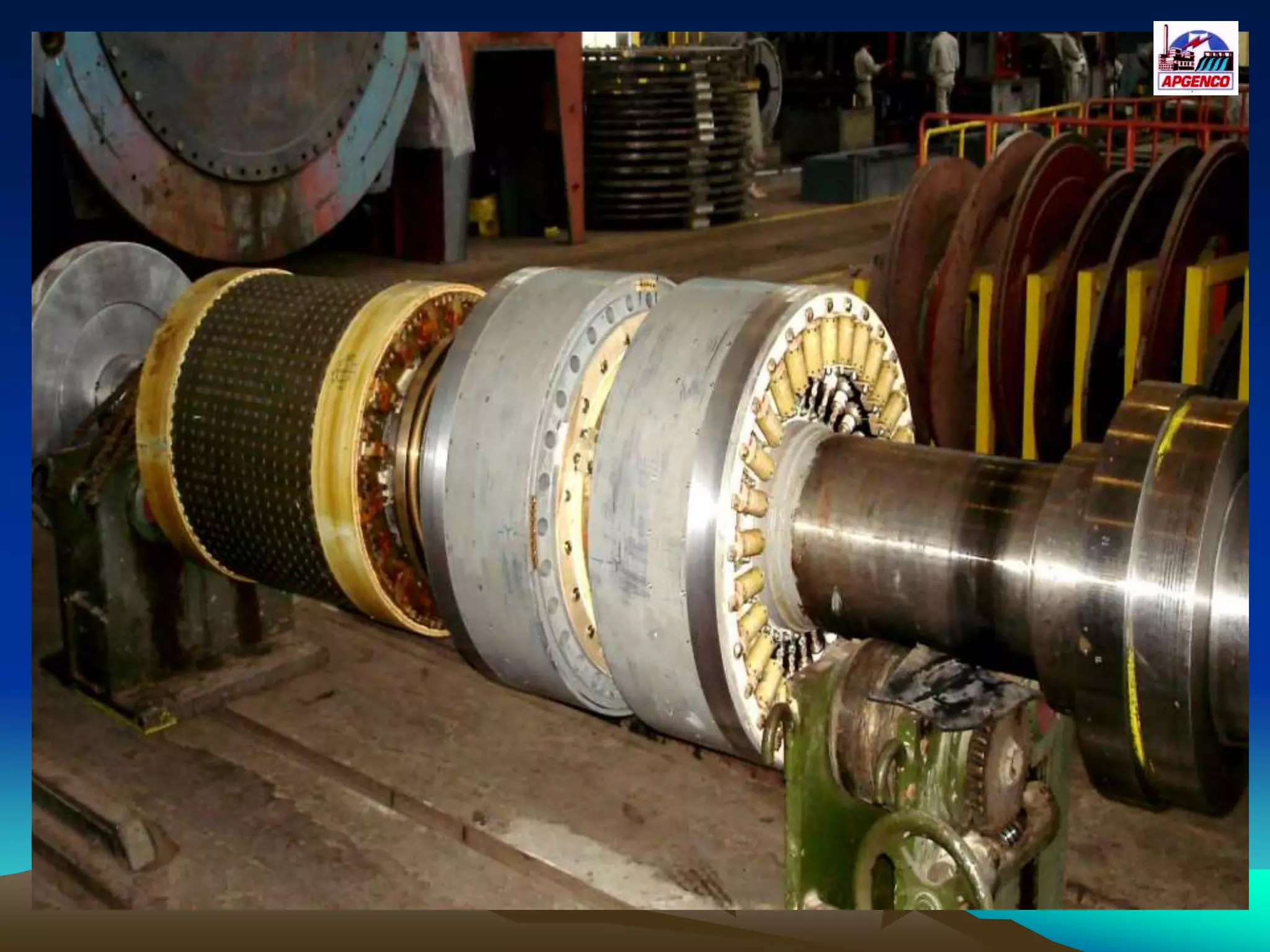

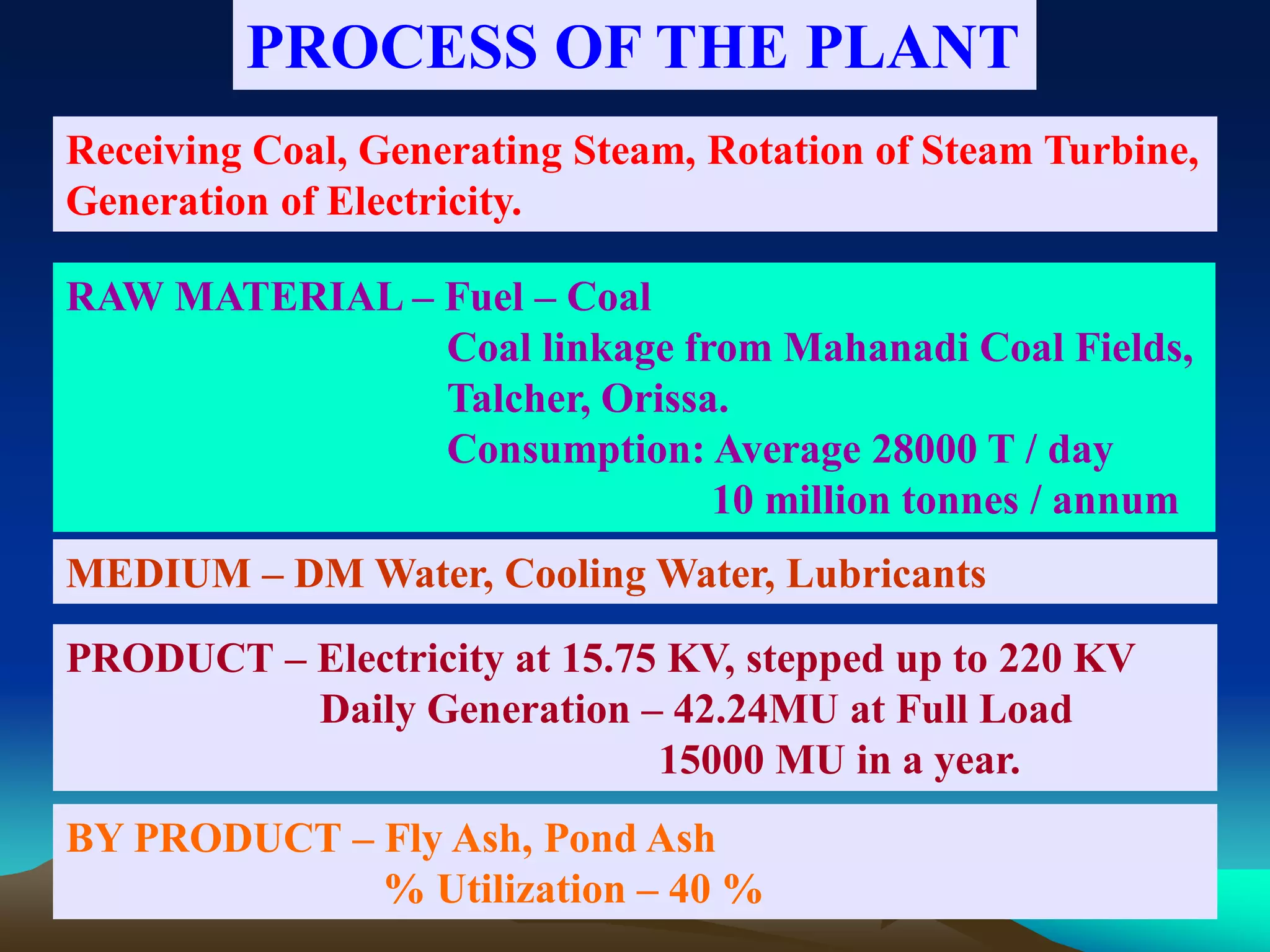

The document discusses thermal power plants, specifically detailing the components and operations of a thermal power station, including coal handling, boiler systems, turbine mechanics, and energy transformation processes. It outlines the installed capacity of various units, describes the stages of construction, and elaborates on equipment such as fans, mills, and generators. Additionally, the text covers safety measures, waste management, and ash utilization methods employed in the power generation process.