Embed presentation

Download as PDF, PPTX

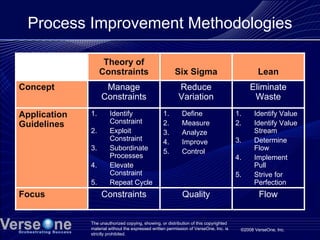

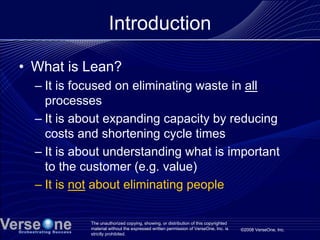

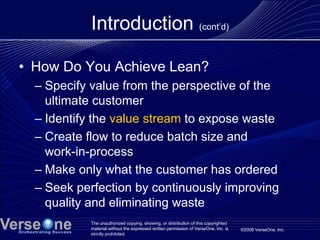

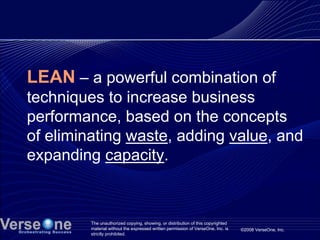

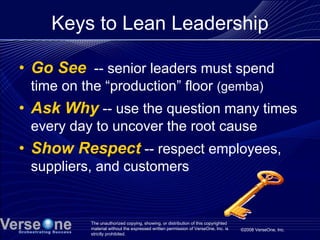

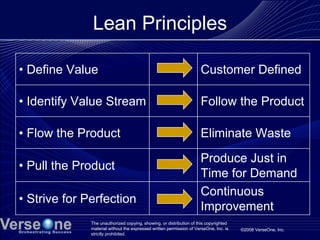

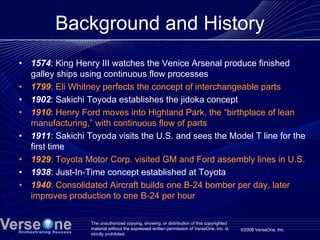

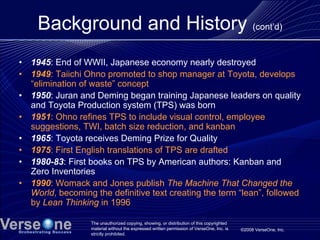

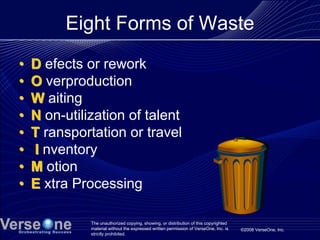

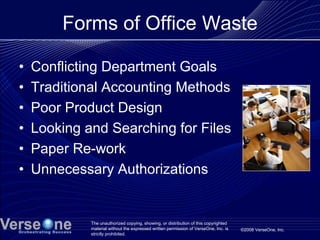

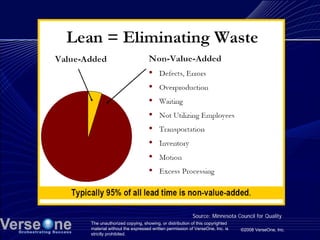

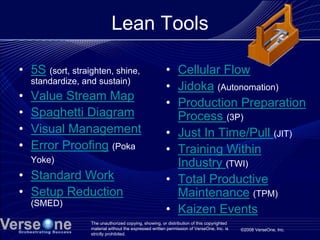

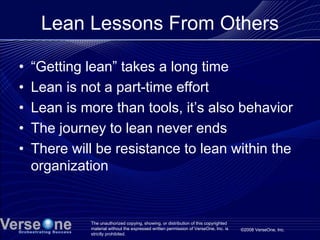

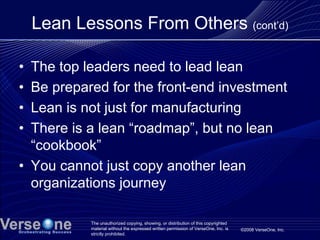

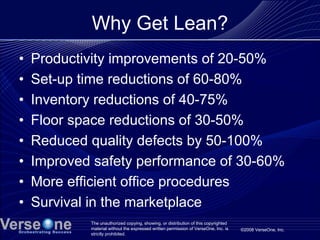

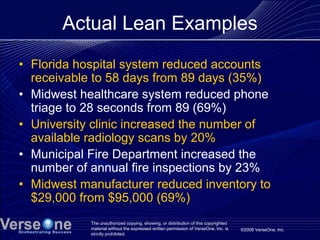

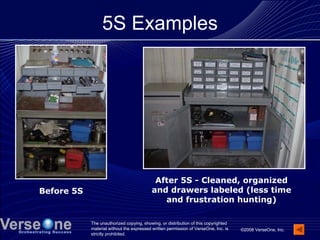

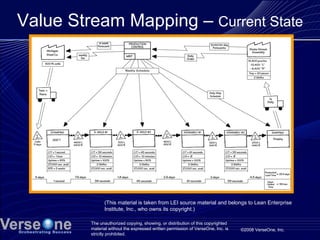

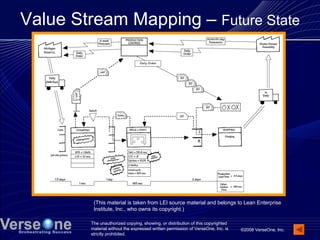

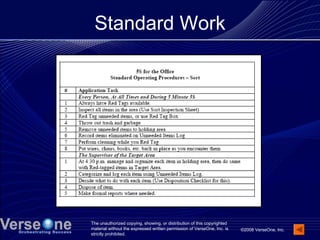

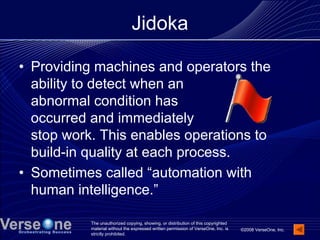

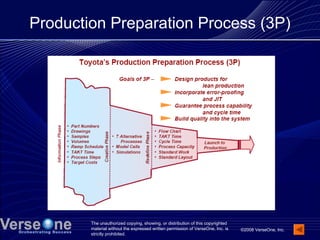

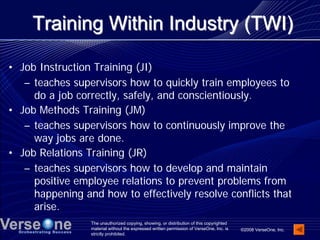

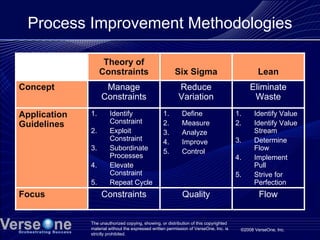

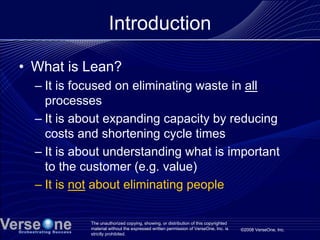

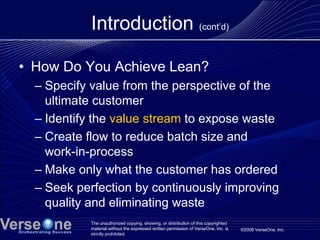

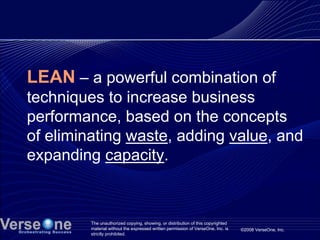

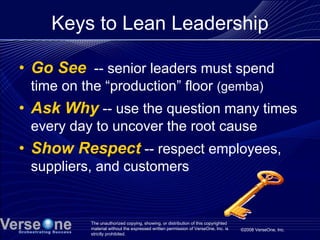

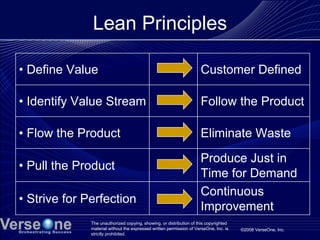

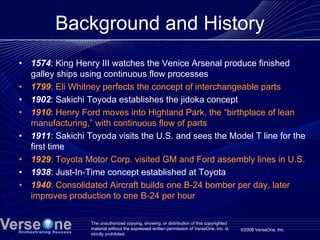

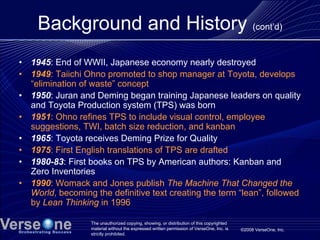

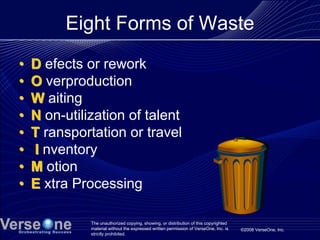

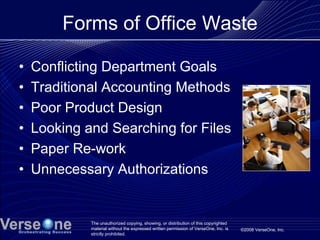

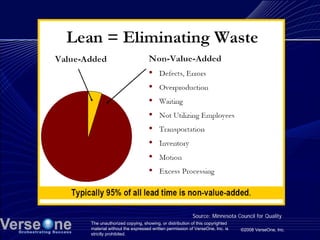

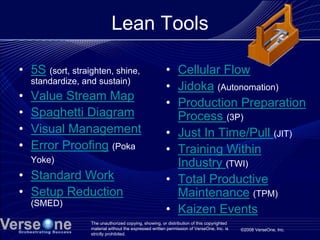

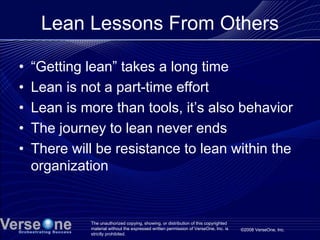

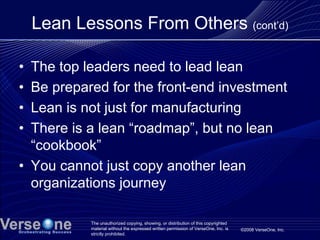

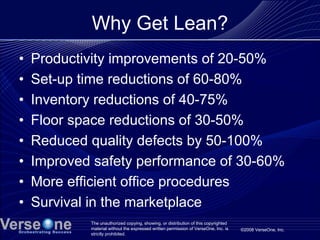

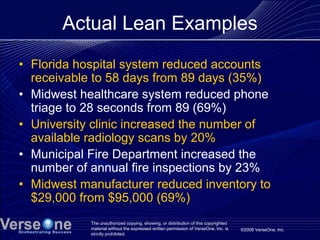

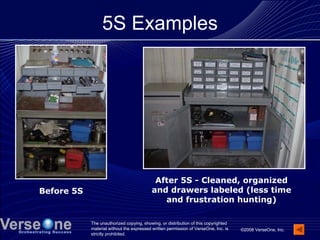

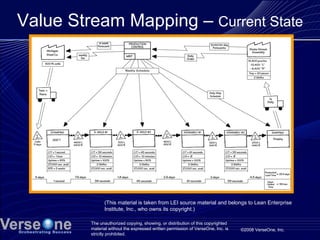

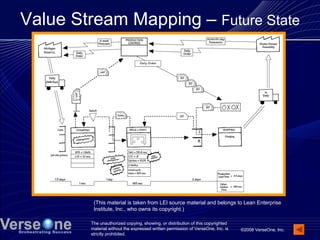

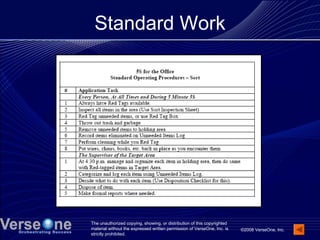

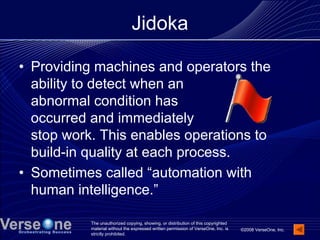

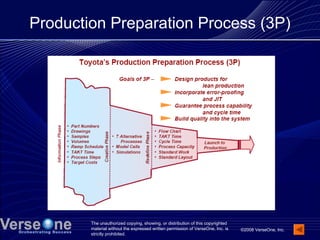

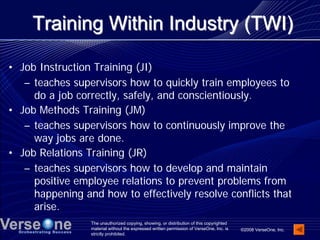

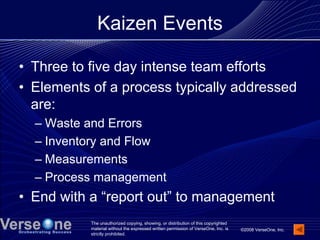

This document outlines the principles and practices of lean methodologies, emphasizing the elimination of waste and the importance of customer value. It discusses key leadership roles, lean tools, and historical context, while providing examples of successful implementations in various sectors. Additionally, it highlights the ongoing journey and commitment required for effective lean transformation in organizations.