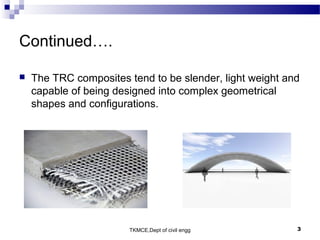

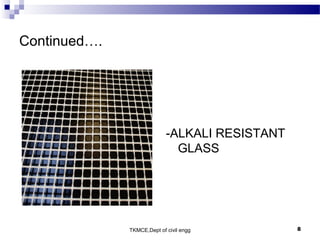

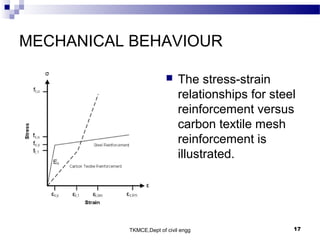

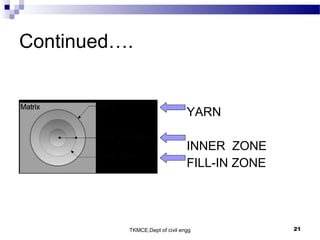

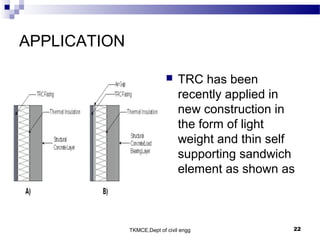

Textile reinforced concrete (TRC) is a composite material where textile reinforcements made of high performance fibers are embedded in a cementitious matrix. The textile reinforcement provides enhanced tensile strength, ductility, and allows TRC composites to be slender, lightweight, and formed into complex shapes. Common fiber materials used in TRC include glass, carbon, basalt, aramid, and polyvinyl alcohol coated with polyvinyl chloride. TRC has applications in thin, self-supporting building elements and in strengthening existing structures.