The document outlines the history and development of fiber reinforced concrete (FRC) from its ancient origins to modern applications. It discusses various types of fibers used, their mechanical properties, advantages and disadvantages, as well as the implications for construction technology. Additionally, it highlights ongoing research and the future potential of advanced materials like textile reinforced concrete.

![Approximately 3500 years ago,

sun-baked bricks reinforced

with straw or horse hair were

used to build the 57 m high hill

of Aqar Quf (near present-day

Baghdad) [1].

Fibre-reinforced cement-products

were invented in the late 19th

century by the Austrian Ludwig

Hatschek. He mixed 90% cement

and 10% asbestos fibres with water

and ran it through a cardboard

machine, forming strong thin

sheets [2]. Early 1900 saw the use

of asbestos fiber.

In 1950 fiber reinforced concrete

was becoming a field of interest

as asbestos being a health risk

was discovered. The steel and

glass fibers that were used in the

early work on FRC in the 1950s

and 1960s were straight and

smooth [3].

HISTORY](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-4-320.jpg)

![Serious theoretical studies of

FRC began only in the early

1960s, with the work of

Romualdi and his colleagues

[e.g. Romualdi & Batson 1963;

Romualdi & Mandel 1964]. Since

then there was no looking back,

glass, steel, polypropylene fiber

were used in concrete [3-5].

Since 1960s, more complicated

geometries of fibers have been

developed, mainly to modify their

mechanical bonding with the

cementitious matrix. Thus, modern

fibers may have profiled shapes,

hooked or deformed ends [6].

Beside the previous

development, by following

decade, fibers may occur as

bundled filaments or fibrillated

films, or they may be used in

continuous form (mats, woven

fabrics, textiles) [7].

HISTORY](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-5-320.jpg)

![Properties

of fibers

As the main parameter, the

proprieties of fibers could have

an enormous influence on the

FRC properties directly like:

the ratio of length to diameter of a fiber in which the diameter may be an equivalent

diameter. This parameter has an important role in FRC mechanical properties [7].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-8-320.jpg)

![A compilation of mechanical properties of commonly used fibers in concrete materials [7]

Reference ACI 544.5R-10](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-12-320.jpg)

![Volume of

fiber

Figure1- Effect of the volume of

steel fibers on the strength and

toughness of SFRC [8].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-15-320.jpg)

![Volume of

fiber Figure 2-Effect of the volume fraction of fibers

on the compressive stress-strain curve [9].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-16-320.jpg)

![Volume of

fiber

Figure 3-Effect of reinforcement ratio (Fiber

content) on mean crack spacing [10].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-17-320.jpg)

![Aspect ratio

of fiber Figure 4-Influence of the aspect ratio of fibers

on the compressive stress-strain curve [9].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-18-320.jpg)

![Geometry

of fiber

Figure5-Influence of the fiber type on

the force-displacement curves [11].](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-19-320.jpg)

![Fiber-reinforced concrete promises to

provide a long-term solution to bridge deck

problems [13].

5

Mackenzie River Twin Bridges, Ontario, Canada](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-33-320.jpg)

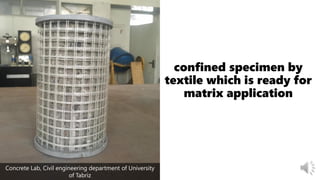

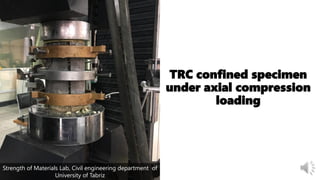

![A new technology

Textile reinforced concrete (TRC) is a composite material consisting of a cement-based

matrix with typically small maximum aggregate grain sizes and high-performance

continuous multifilament yarns made of alkali-resistant (AR) glass, carbon, polymer, or

other materials [14].

TRC](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-39-320.jpg)

![References [4] Romualdi, J.P. & Batson, G.B. 1963. Mechanics of

crack arrest in concrete, Journal of Engineering

Mechanics 89: 147-168.

[5] Romualdi, J.P. & Mandel, J.A. 1964. Tensile strength

of concrete affected by uniformly dispersed and

closely spaced short lengths of wire reinforcement,

Journal of the American Concrete Institute 61: 657-

672.

[6] Bentur, A. and Mindess, S., Fiber Reinforced Cementitious

Composites, Elsevier Applied Science, 1990, pp. 1-2.

[7] ACI Committee 544, Report on the Physical Properties and

Durability of Fiber-Reinforced Concrete, American Concrete

Institute, Farmington Hills, MI 48331, 2010.

[8] S.P. Shah and V.B. Rangan, ‘Fiber reinforced concrete

properties’, J. American

Concrete Institute. 68, 1971, 126–135.

[9] ACI Committee 544, Design Considerations for Steel Fiber

Reinforced Concrete, American Concrete Institute, Farmington

Hills, 1999.

[1] R.N. Swamy, ‘Prospects of fibre reinforcement in

structural applications, in Advances in Cement-Matrix

Composites’, Proc. Symp. L, Materials Research Society

General Meeting, Boston, MA, Nov. 1980, Materials Research

Society, University Park, PA (now Pittsburgh, PA), 1980, pp.

159–169.

[2] Ooe. Landesarchiv (ed.), Oberoesterreicher, vol. 2, 1982;

NDB.

[3] Mindess S, ’Thirty years of fibre reinforced concrete

research at the UWM British Colombia’, In

Proceedings of an International Conference on Sustainable

Construction Materials and Technologies (Kraus RN, Naik TR,

Claisse P and Sadeghi-Pouya H (eds)). CBU, University of

Milwaukee, USA.](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-46-320.jpg)

![References

[13] Krstulovic-Opara, N.; Haghayeghi, A. R.; Haidar, M.; and

Krauss, P. D., 1995, “Use of Conventional and High-Performance

Steel Fiber-Reinforced Concrete for Bride Deck

Overlays,” ACI Materials Journal, V. 92, No. 6, Nov.-Dec.,

pp. 669-677.

[14] Brameshuber, W. (Ed.), 2006. Textile reinforced concrete:

report no. 036 of the RILEM

State-of-the-Art Report, RILEM Technical Committee 201-TRC.

[10] R. Deluce, Jordon & J. Vecchio, Frank. (2013). Cracking

behavior of steel fiber-reinforced concrete members

containing conventional reinforcement. ACI Structural

Journal. 110. 481-490.

[11] Tutankhamun Sami Sharif, ’Effect of fiber shape on

mechanical behavior of steel fiber in fiber reinforced

concrete FRC’. African Journal of Physics Vol. 3 (5), pp. 105-

109, May, 2016.

[12] Balaguru, P. and Shah, S. (1992). Fiber-reinforced cement

composites. New York: McGraw-Hill, p.343.](https://image.slidesharecdn.com/linkedinfrc-171230215456/85/Fiber-reinforced-concrete-47-320.jpg)