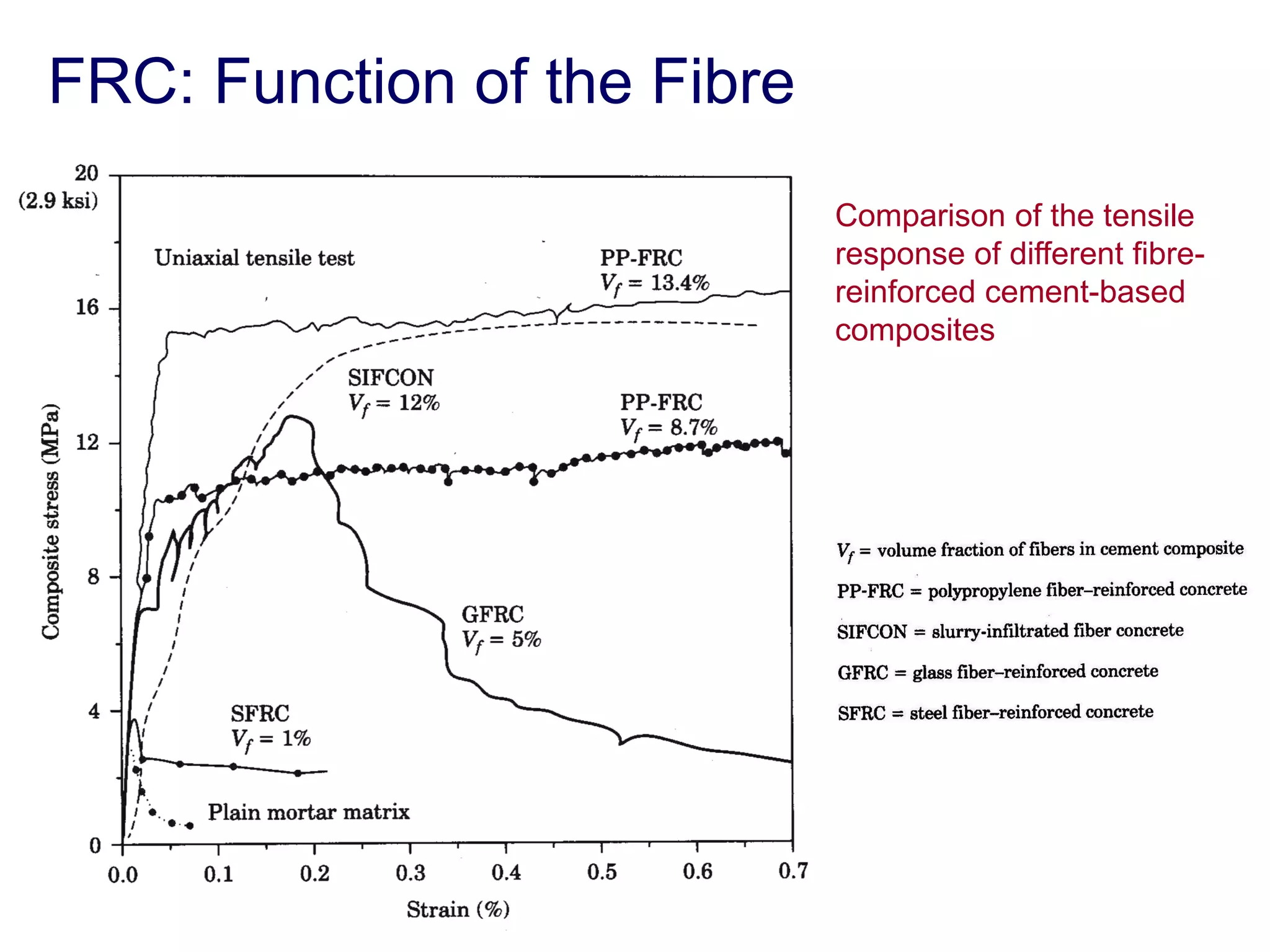

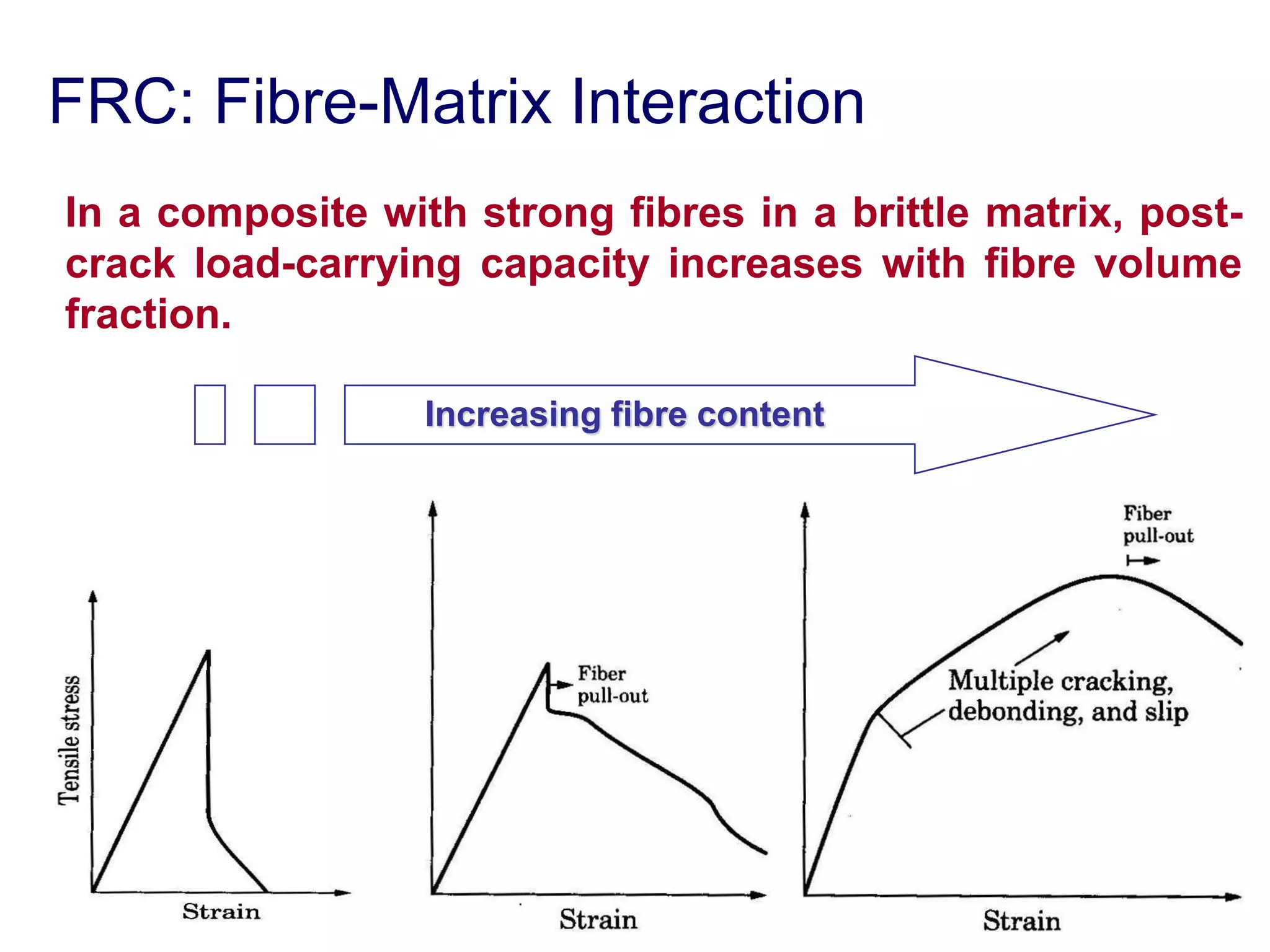

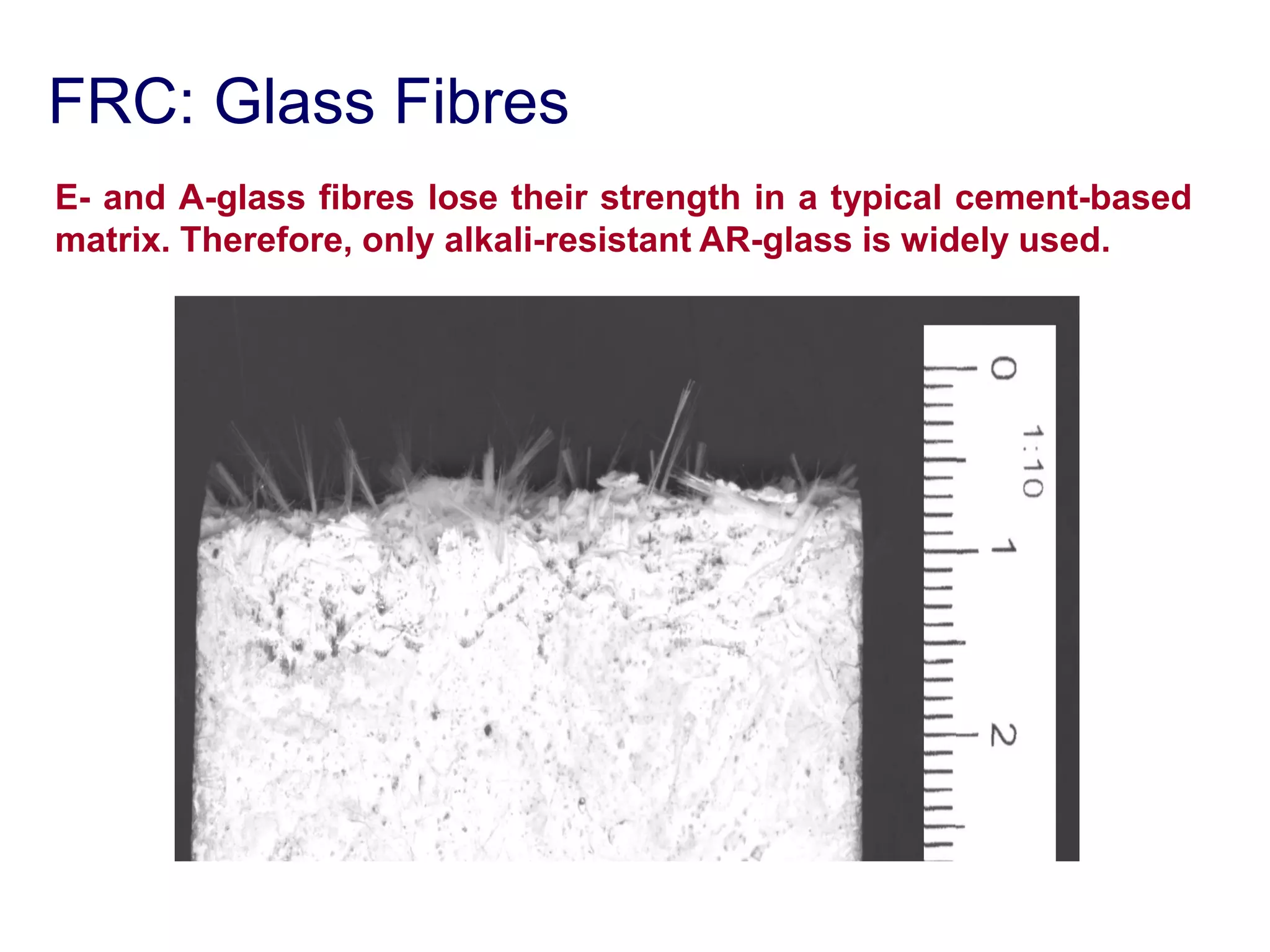

Fibre reinforced concrete (FRC) is concrete containing short discrete fibres that are uniformly distributed. FRC can be made with a variety of fibre materials including steel, polypropylene, glass, carbon and natural fibres. The fibres increase the toughness and tensile strength of concrete to control cracking. Common applications of FRC include industrial floors, shotcrete and precast concrete elements where its improved mechanical properties and durability are beneficial.