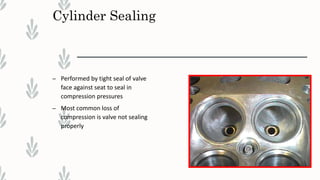

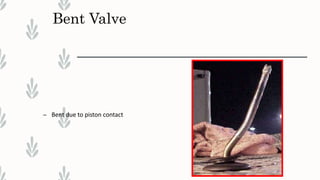

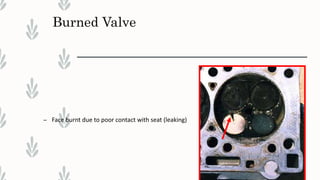

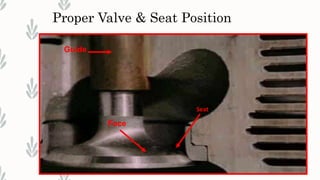

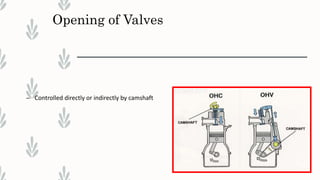

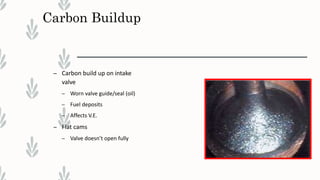

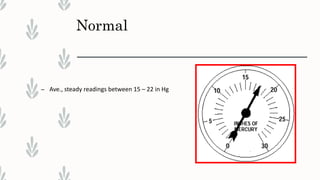

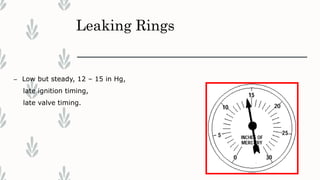

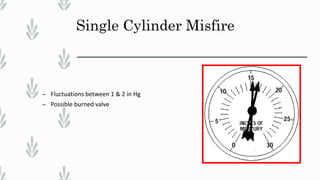

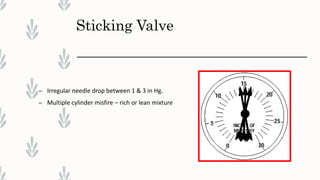

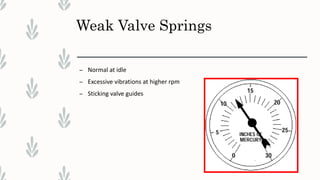

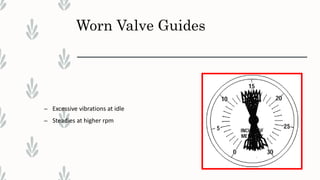

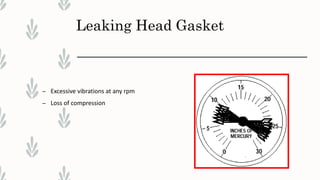

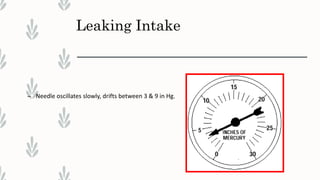

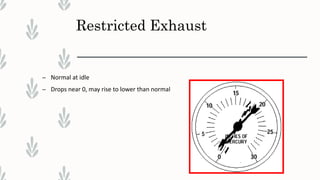

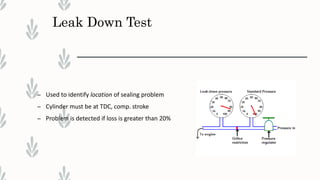

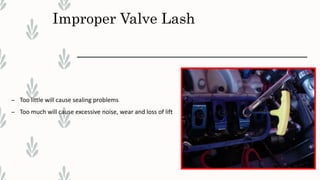

The document discusses the characteristics and performance testing of diesel engines, including their operation through various strokes and the importance of factors like thermal efficiency and air-fuel ratio. It details issues related to engine sealing, valve function, and volumetric efficiency and describes several testing methods such as compression tests and vacuum testing to diagnose engine problems. Overall, it emphasizes the critical aspects influencing the efficiency and performance of diesel engines.