Embed presentation

Download to read offline

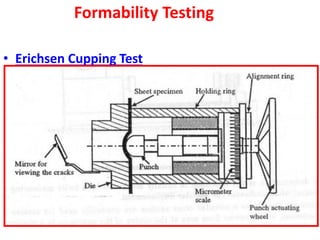

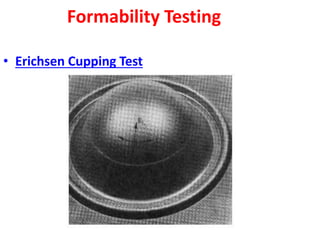

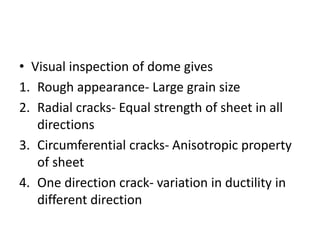

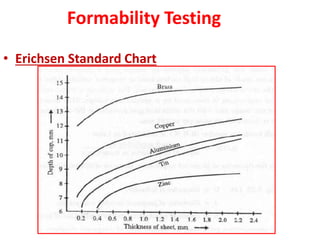

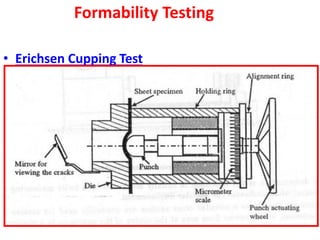

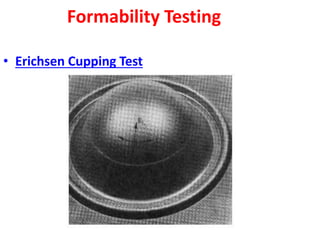

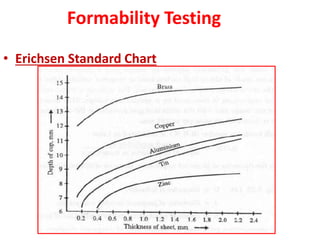

The document discusses the Erichsen cupping test for evaluating the formability of sheet metals. It defines formability as the ability of a sheet to be formed into a specific shape. Formability depends on parameters like strain hardening coefficient, strain rate sensitivity index, and plastic strain ratio. The Erichsen cupping test involves drawing a hemispherical dome in a sheet metal and visually inspecting it for defects like radial or circumferential cracks that provide information about the material's grain size, anisotropy, and ductility in different directions. Results are compared to standard charts to evaluate formability.