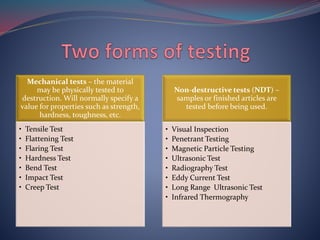

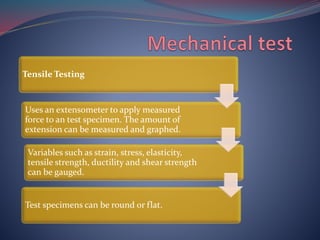

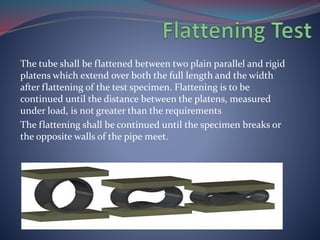

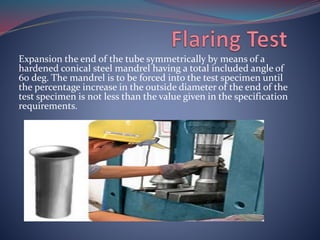

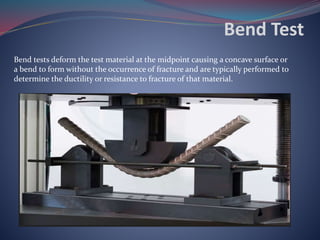

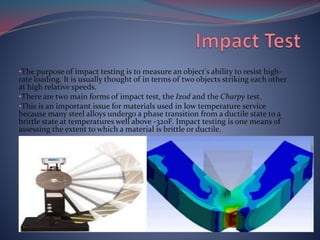

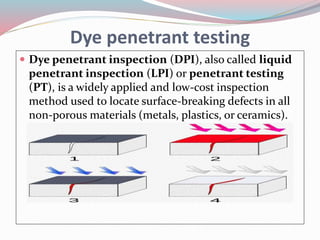

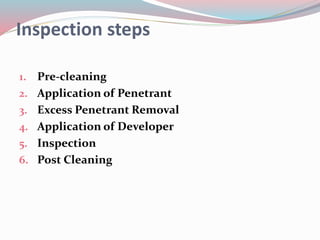

This document discusses various quality control and materials testing methods. It describes mechanical tests like tensile, flattening, and hardness tests that physically test materials. It also discusses non-destructive tests like visual inspection, magnetic particle testing, and ultrasonic testing that inspect samples without damaging them. Specific testing methods are then outlined in more detail, including how tensile testing measures properties under loads, how bend tests evaluate ductility, and how dye penetrant testing locates surface defects using developer dyes.