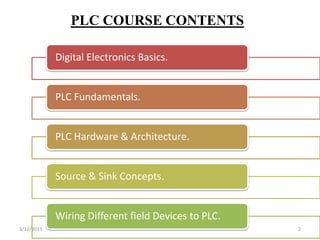

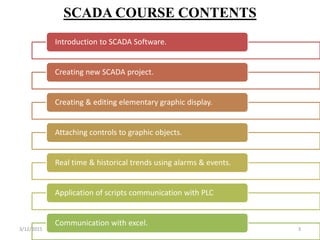

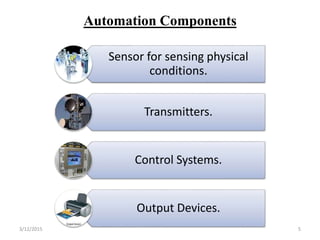

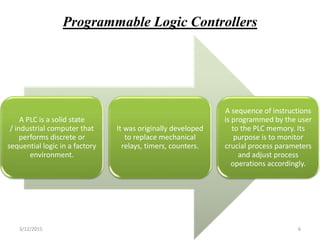

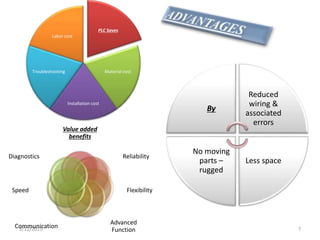

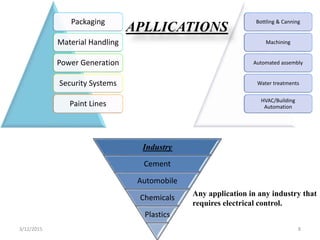

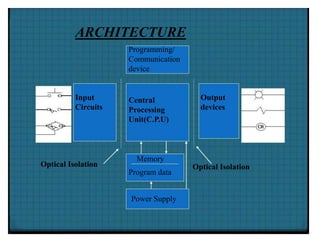

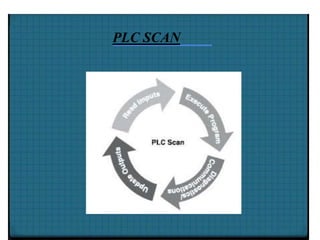

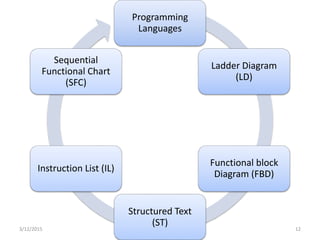

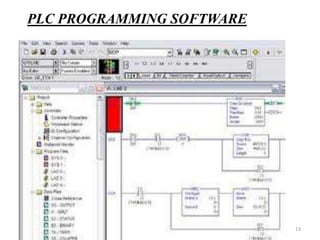

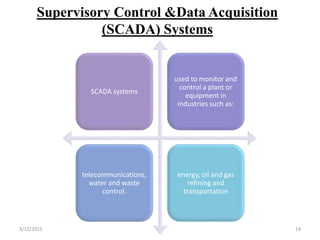

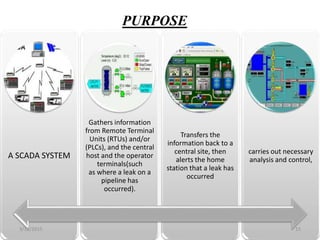

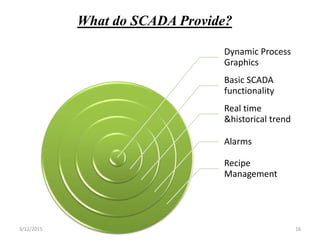

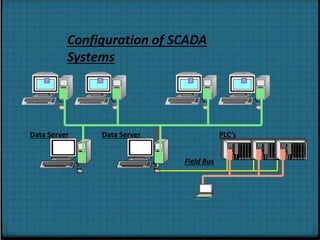

The document discusses programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems. It provides an overview of PLC and SCADA course contents, including digital electronics, hardware, programming, and communication. It also describes automation components, PLC applications in various industries, PLC architecture involving input/output devices and a central processing unit, and common PLC programming languages and software. Finally, it outlines the purpose and basic functions of SCADA systems for monitoring and controlling industrial plants and equipment.