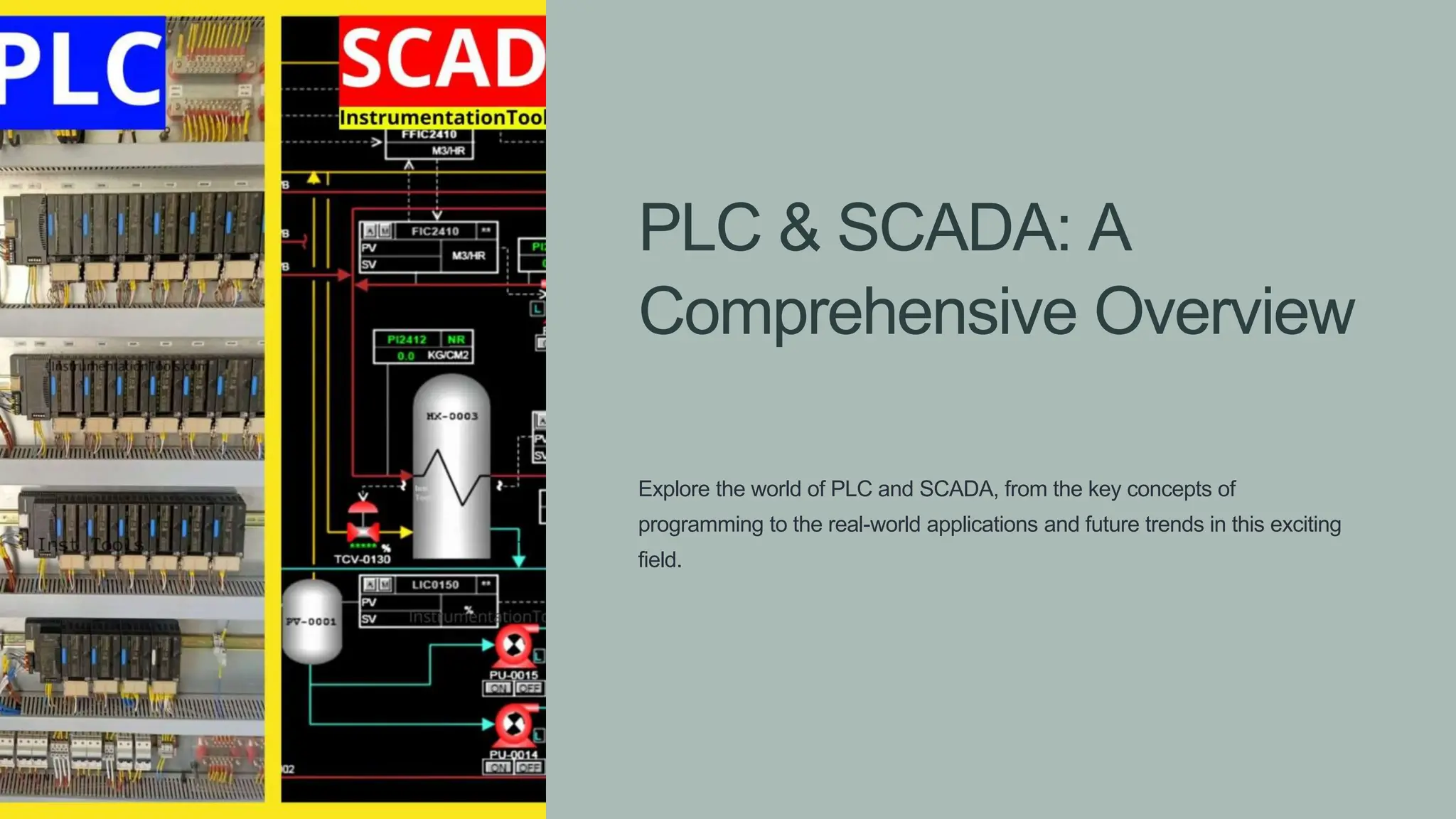

The document provides a comprehensive overview of PLC and SCADA technologies, covering programming principles, components, and various communication protocols like Modbus and DNP3. It highlights the advantages, limitations, and real-world applications in industries such as manufacturing, energy, and water management, while discussing future trends including cloud and edge computing. The conclusion emphasizes the transformative impact of these technologies and the potential for further advancements with AI integration.