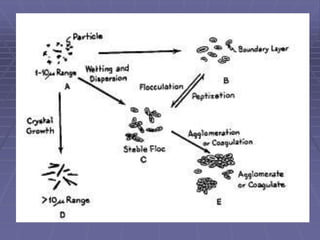

Suspensions are liquid dosage forms containing finely dispersed solid particles. They are used for drugs that are insoluble, unstable, or need to be absorbed slowly. Suspensions can be administered orally, ocularly, otically, rectally, parenterally, or topically. Factors in formulation include the nature and size of particles, viscosity, and physical stability. Structured vehicles and controlled flocculation are used to prepare deflocculated and flocculated suspensions, respectively. Evaluation tests assess properties like sedimentation, redispersibility, and zeta potential. Packaging requires containers with headspace and instructions to shake before use.

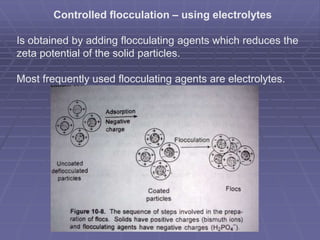

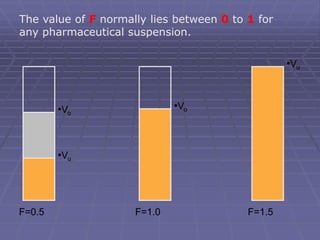

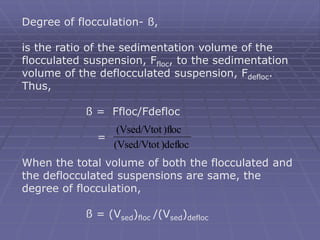

![Sedimentation volume, F, of a suspension is expressed by

the ratio of the equilibrium volume of the sediment, Vsed

[Vu] to the total volume, Vtot [Vo] of the suspension.

Thus, F = Vsed/Vtot = [Vu] / [Vo]

The value of F provides a qualitative knowledge

about the physical stability of the suspension.

Also used as one of the quality control tool- it is

simple to estimate

Higher the F, more stable the suspension is.](https://image.slidesharecdn.com/suspensions-230831152223-6a69fb2a/85/SUSPENSIONS-ppt-13-320.jpg)

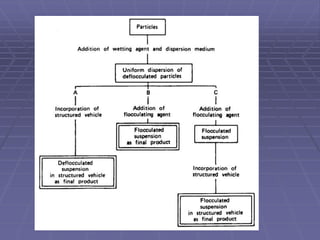

![METHODS OF PREPARATION

Aim is to prepare physically stable suspensions [desired one

is deflocculated or flocculated]. Hence the normal ways of

doing so are

(1) use of structured vehicle – for deflocculated suspension

(2) use of controlled flocculation – for flocculated suspension

- using electrolytes

- using surfactants

- using polymers

and

(3) Controlled flocculation – structured vehicle](https://image.slidesharecdn.com/suspensions-230831152223-6a69fb2a/85/SUSPENSIONS-ppt-19-320.jpg)

![Structured vehicle – Deflocculated suspension

Structured vehicles are the aqueous solutions of natural and

synthetic gums. – act by entrapping the particles [generally

deflocculated particles]

MC, CMC, sodium CMC, acacia, and tragacanth are the

most commonly used structured vehicle in the

pharmaceutical suspensions. [suspensions will be plastic

and pseudo plastic]

Suspensions of higher solids content are prepared

(e.g. toothpaste) using a combination of a clay and

a gum (e.g. NaCMC)

Hydrocolloids are also used as they hydrate well with water

and swell increasing viscosity.

Eg., Nonionic -- MC, HPMC

Ionic -- Sodium CMC, Cabopol

Clays -- Bentonite](https://image.slidesharecdn.com/suspensions-230831152223-6a69fb2a/85/SUSPENSIONS-ppt-24-320.jpg)

![Structured vehicle – Deflocculated suspension

Hence, these structured vehicles act as suspending

agents

and the concentration depends on

- Viscosity of vehicle – influence stability

- Amount of solids – adding clays calls for use of

preservatives [methyl and propyl parabens]

- Particle size

- Density of solids – density of structured vehicles

increased by including PVPs, PEGs,

sugars, Glycerine](https://image.slidesharecdn.com/suspensions-230831152223-6a69fb2a/85/SUSPENSIONS-ppt-25-320.jpg)