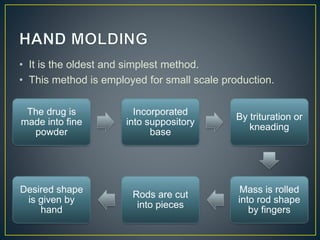

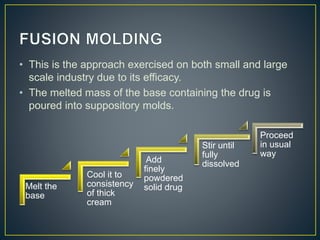

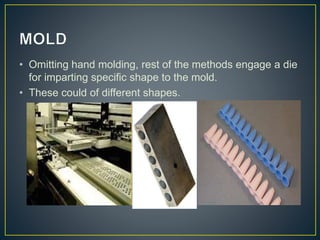

This document discusses four methods for manufacturing suppositories: hand rolling, compression molding, fusion molding, and automatic molding. Hand rolling is the oldest and simplest method, involving mixing the drug powder into a suppository base and manually rolling it into rods that are then cut. Compression molding compresses the drug-base mixture into molds using a machine. Fusion molding involves melting the base, adding the drug, and pouring the mixture into molds. Automatic molding is the modern method using a machine to completely mold suppositories at high volumes.