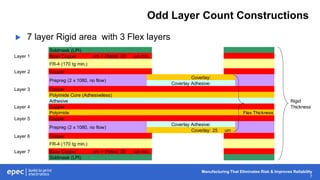

This document discusses various advanced rigid-flex circuit board constructions that offer benefits over standard constructions. It describes options for odd layer counts, asymmetrical constructions, varying flex layer counts, integrated ZIF connections, blind and buried vias, air gap flex layers, multiple rigid area thicknesses, and shielded flex layers. These advanced constructions allow for higher levels of design integration, tighter bend radii, impedance control, and EMI shielding compared to standard constructions.