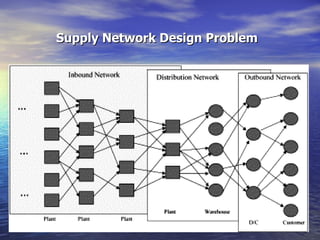

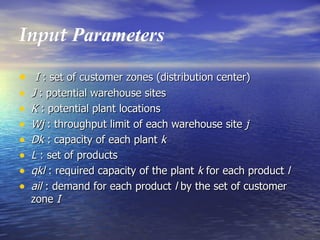

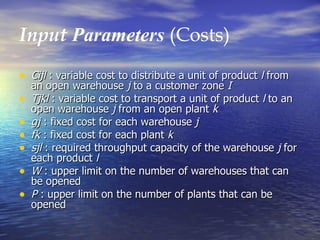

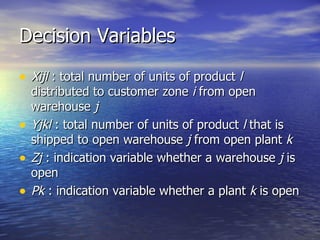

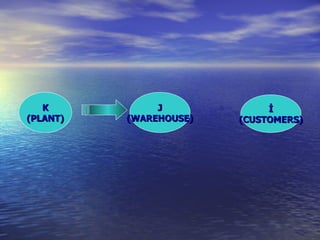

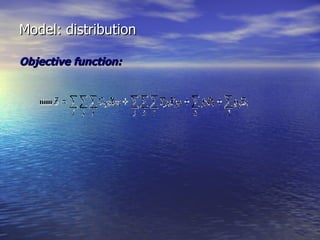

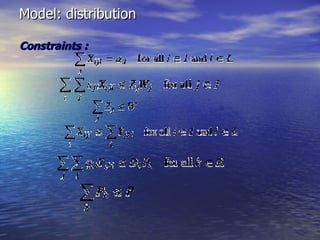

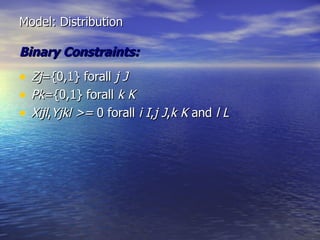

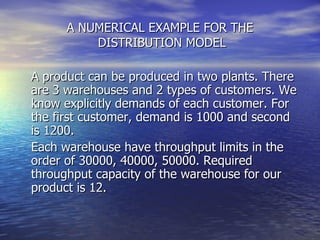

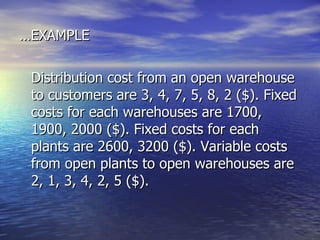

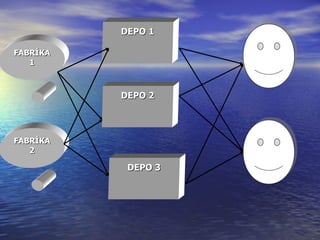

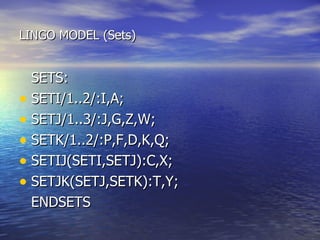

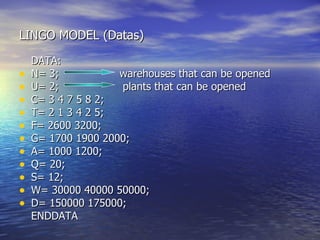

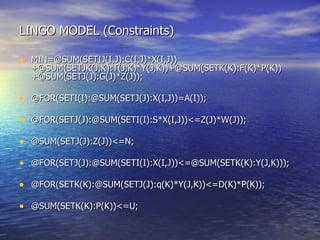

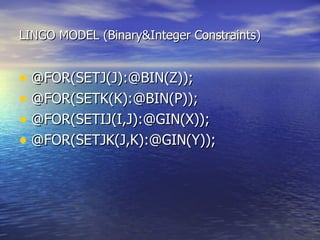

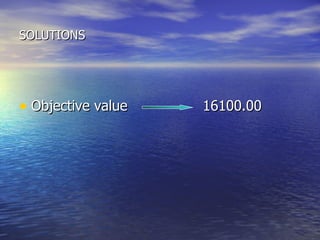

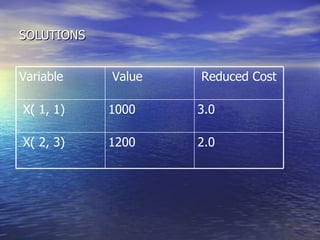

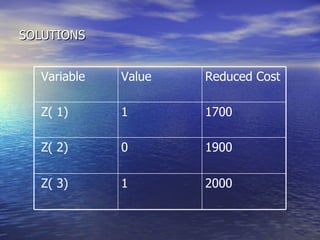

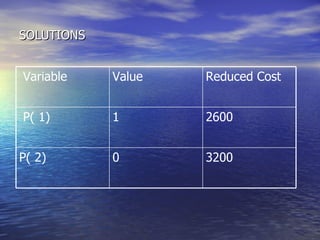

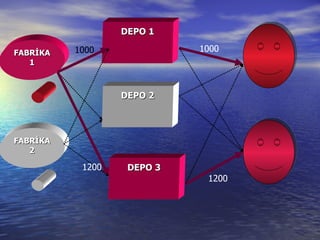

The document summarizes a mathematical model for optimizing a supply network design problem. The model determines the optimal number, location, capacity and configuration of plants, warehouses and distribution centers to meet customer demands at minimum cost. The model considers costs of transportation between facilities and fixed costs of opening facilities. The summary provides an example application of the model to a supply network with 2 plants, 3 warehouses and 2 customer zones.