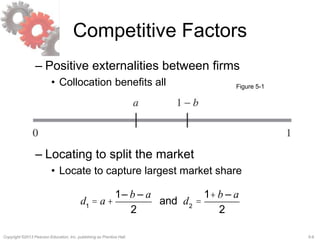

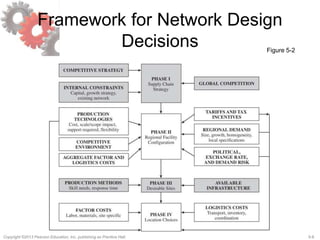

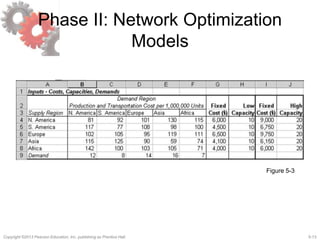

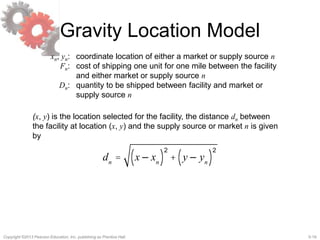

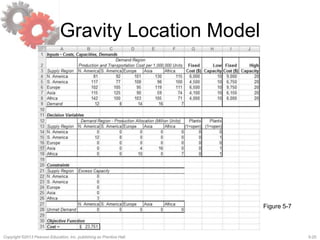

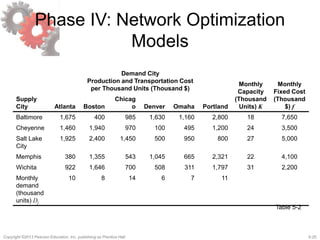

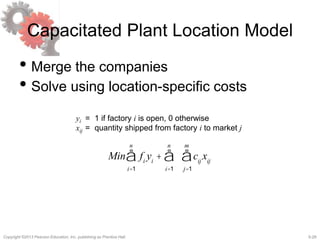

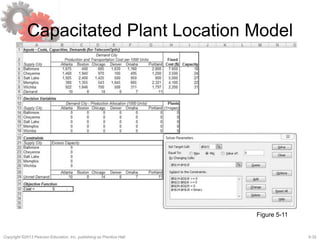

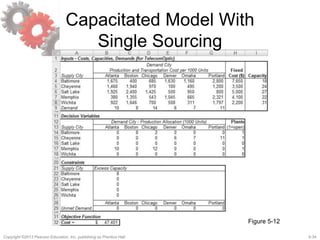

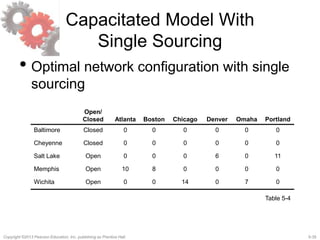

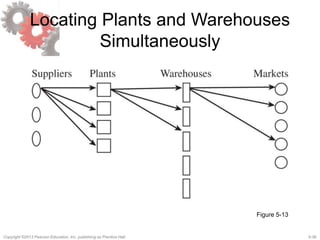

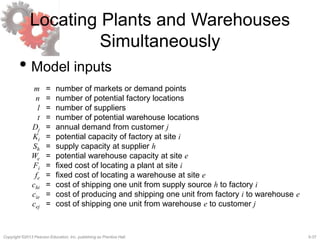

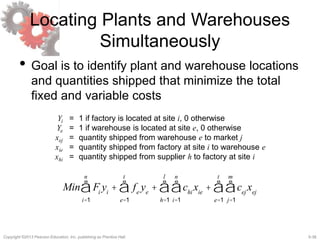

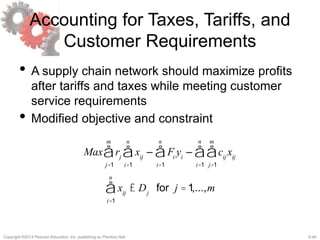

This document discusses network design in supply chains. It begins by outlining the key network design decisions, including facility role, location, capacity allocation, and market/supply allocation. It then discusses factors that influence these decisions, such as strategic, technological, economic, political, infrastructure, and competitive factors. The document presents a framework for network design decisions involving defining strategy, regional configuration, site selection, and location choices. It concludes by describing models that can be used for facility location and capacity allocation decisions, including a capacitated plant location model and gravity location model.