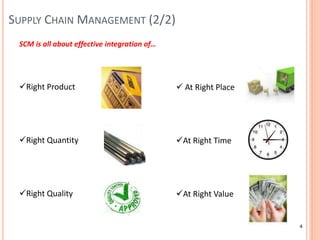

This document outlines a presentation on supply chain management. It defines supply chain management as managing the flow of goods and services from suppliers to customers, including inventory, purchasing, and delivery. The supply chain process involves planning production, sourcing materials, making products, delivering products, and selling to customers. Key performance indicators for supply chain management relate to inventory levels and turnover, purchasing costs, delivery times, order fulfillment rates, and supplier and customer satisfaction.