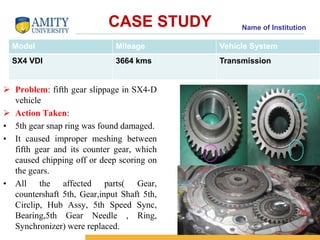

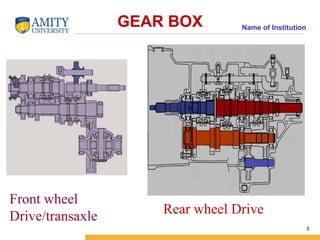

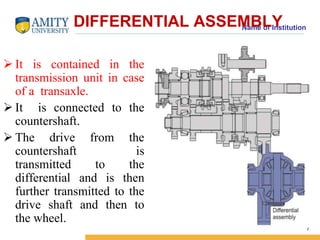

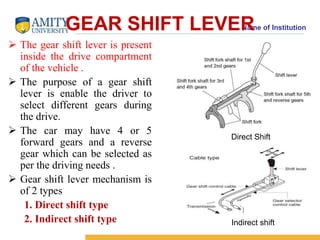

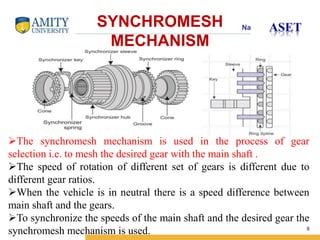

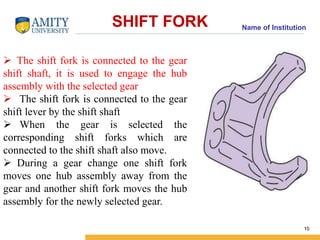

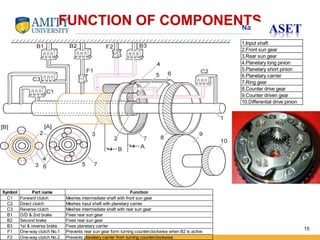

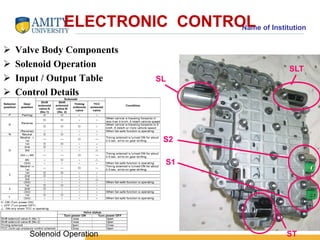

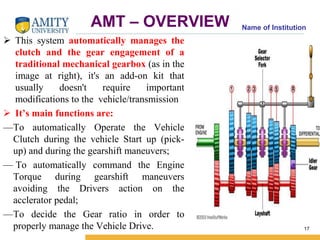

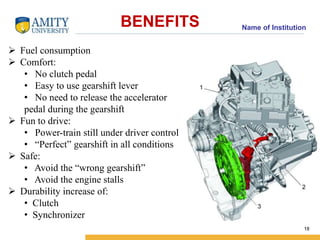

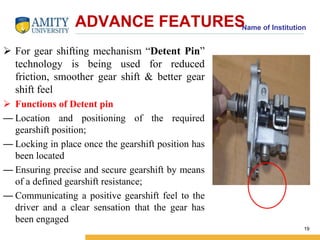

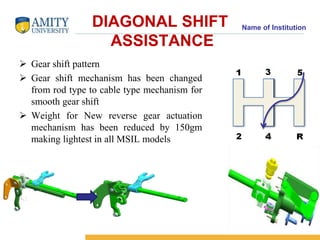

This document summarizes different types of vehicle transmissions, including manual, automatic, and auto-manual transmissions. It describes the key components of a manual transmission like the clutch, gearbox, differential, and drive shaft. Automatic transmissions are introduced as having no clutch and providing smoother gear shifts. An auto-manual transmission is described as automatically operating the clutch and commanding engine torque for gear shifts. Advanced features like detent pins for smoother gear changes are also summarized. The document concludes with a case study of repairing a fifth gear slippage issue in an SX4 vehicle.

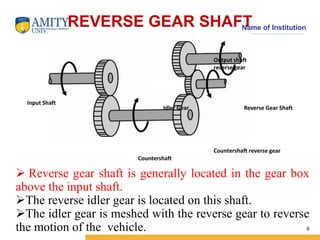

![Name of Institution REVERSE SHIFT

PREVENTION

21

The cubic projection on the gear shift and select

lever is blocked by the projection of reverse shift

limit yoke when gear shift control lever is

shifted from 5th position to reverse position.

1. Gear shift and select lever

2. Reverse shift limit yoke

[A] : 5th

[B] : Reverse

[C] : 4th

As cubic projection of gear shift and select

lever pushes the reverse shift limit yoke, the

yoke rotates and pushes the cubic projection

of the lever toward the neutral position.

Gear is shifted into 4th position if gear shift

and select lever is still pushed toward

reverse position. Reverse shift limit yoke

returns to original position by spring force.](https://image.slidesharecdn.com/summerinternppt-131027013222-phpapp01d-141013151011-conversion-gate02/85/Transmission-In-Maruti-cars-21-320.jpg)