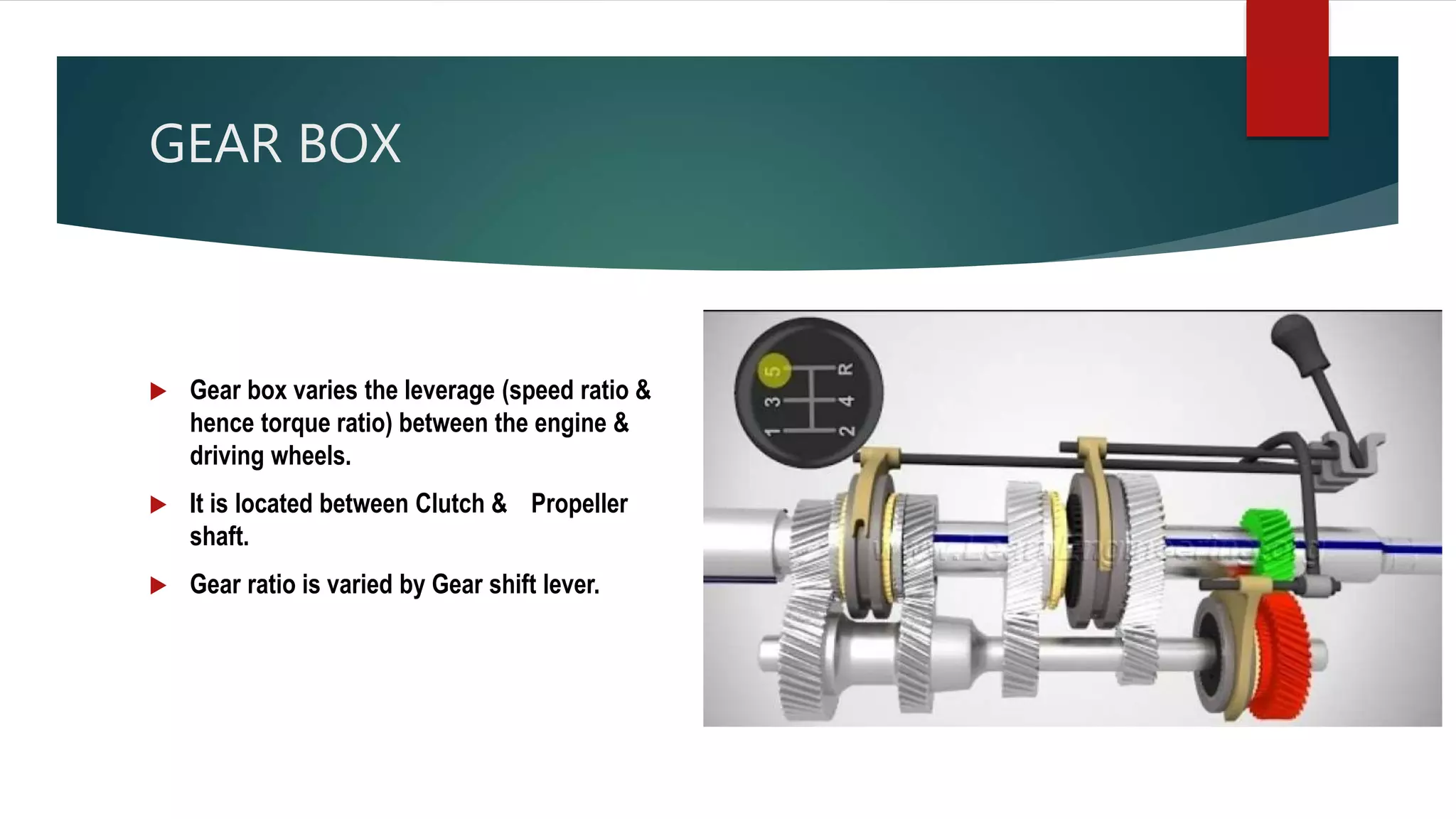

The document summarizes the key components and functions of a vehicle transmission system. It discusses the purpose of transmitting engine torque to drive the wheels. It then describes the main types of transmissions including manual, automatic, CVT, and their basic workings. The document also explains the purpose and function of key components that work together in a transmission system, such as the clutch, gearbox, driveshaft, differential, and universal joints.