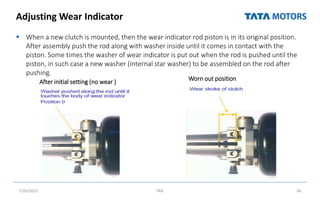

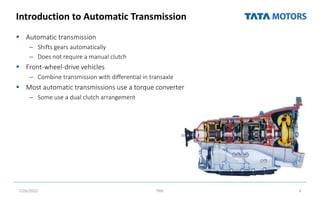

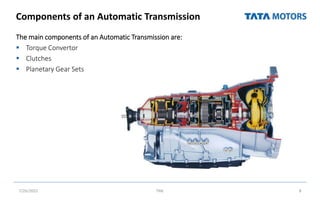

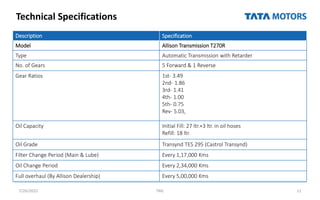

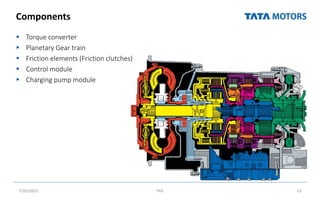

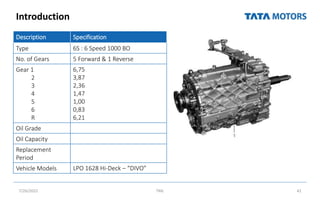

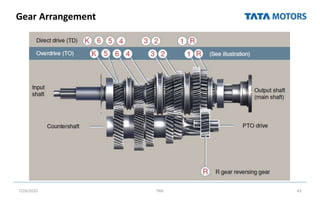

This document provides an overview of a training module on transmission and clutch systems. The module objectives are to perform basic checks, maintenance, dismantling and assembly of transmissions and clutches. The agenda covers Allison automatic transmissions, ZF manual gearboxes, and clutch system overhauling. Preventive maintenance tips are provided for transmissions, including fluid level checks, fluid and filter changes. Components and operation of Allison transmissions are explained. Practical exercises include identifying gearbox components, checking fluid levels, and removing/refitting a gearbox.

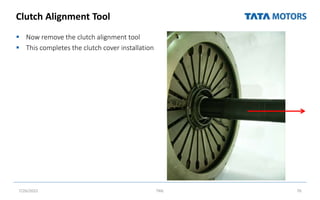

![Clutch Assembly

Remove the two guide studs and crew in

the remaining 2 mounting bolts

Tighten the 12 clutch mounting bolts in

two stages to the correct torque setting

– 22lb/ft [30nm] : Fist Stage

– 43lb/ft [58nm] : Second Stage

The sequence is shown in the image

7/26/2022 TML 74](https://image.slidesharecdn.com/clutchtransmissionsystem-220726075107-4a5d364e/85/Clutch-Transmission-System-pptx-74-320.jpg)