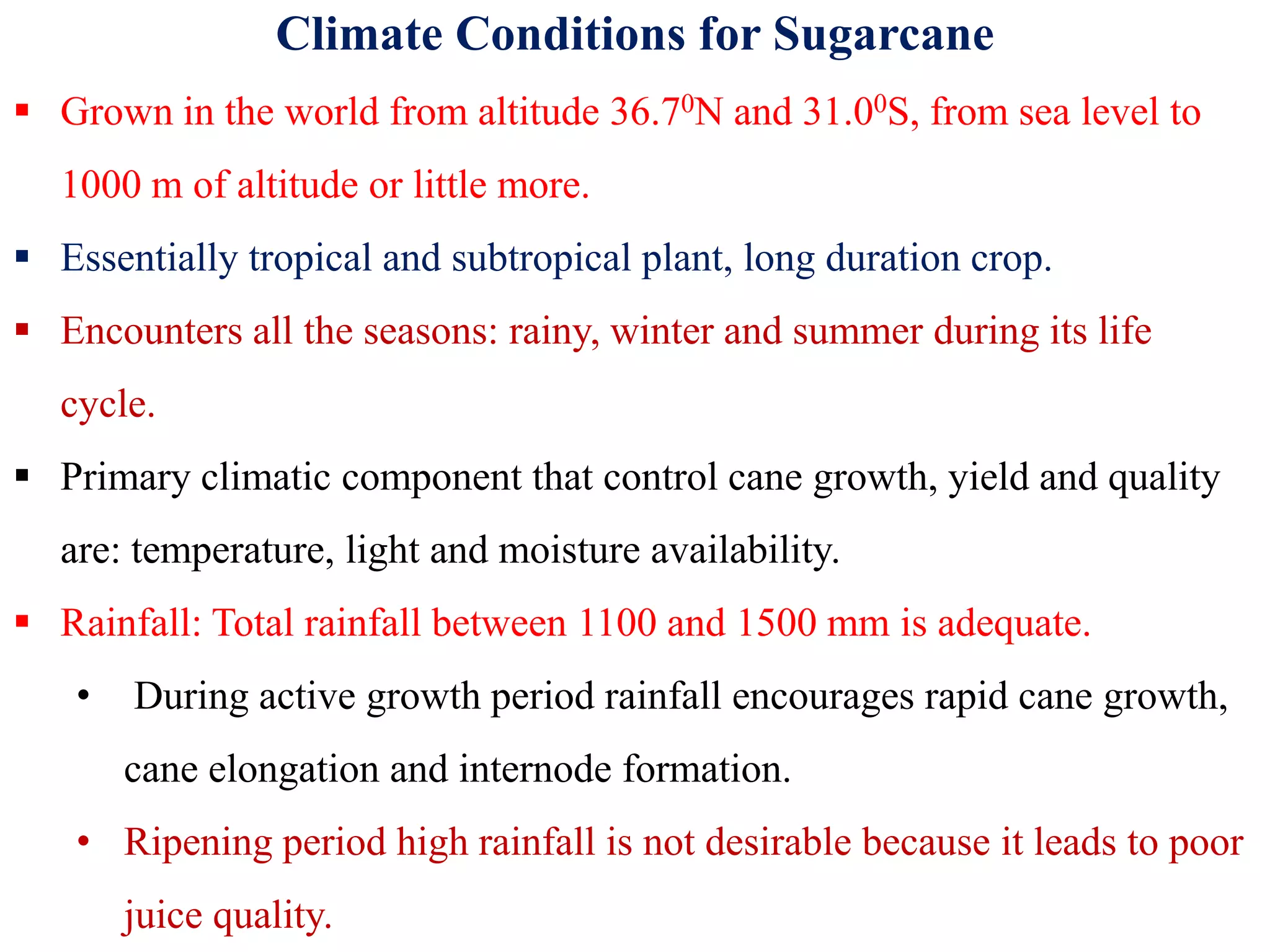

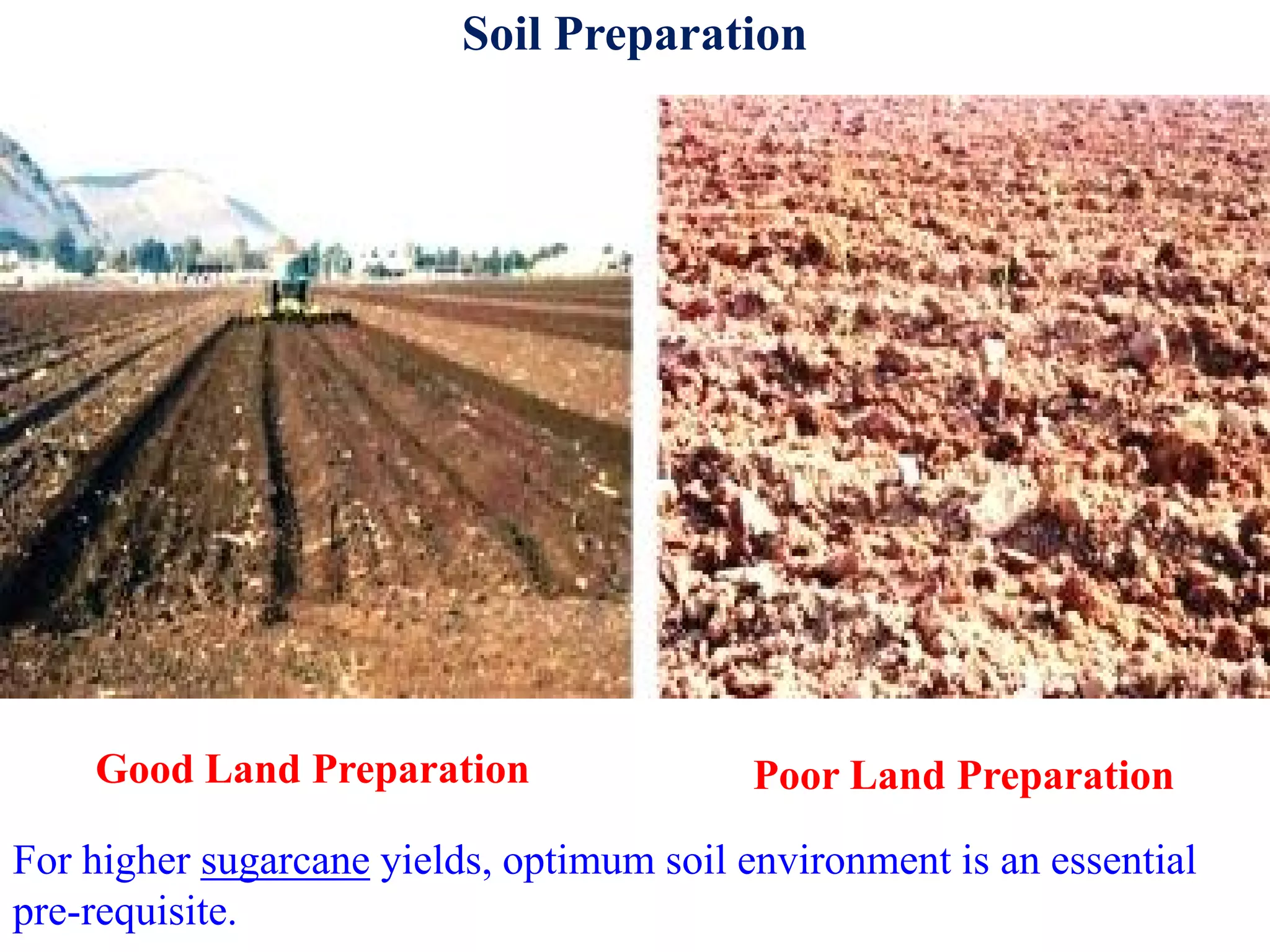

The document is a comprehensive presentation on sugar technology, covering the basics of sugarcane including its classification, botany, and economic significance as a cash crop. It discusses sugarcane's morphology, cultivation practices, and the essential climatic and soil conditions for optimal growth. Additionally, it emphasizes the importance of sugarcane as a primary source of sugar worldwide and its various by-products.

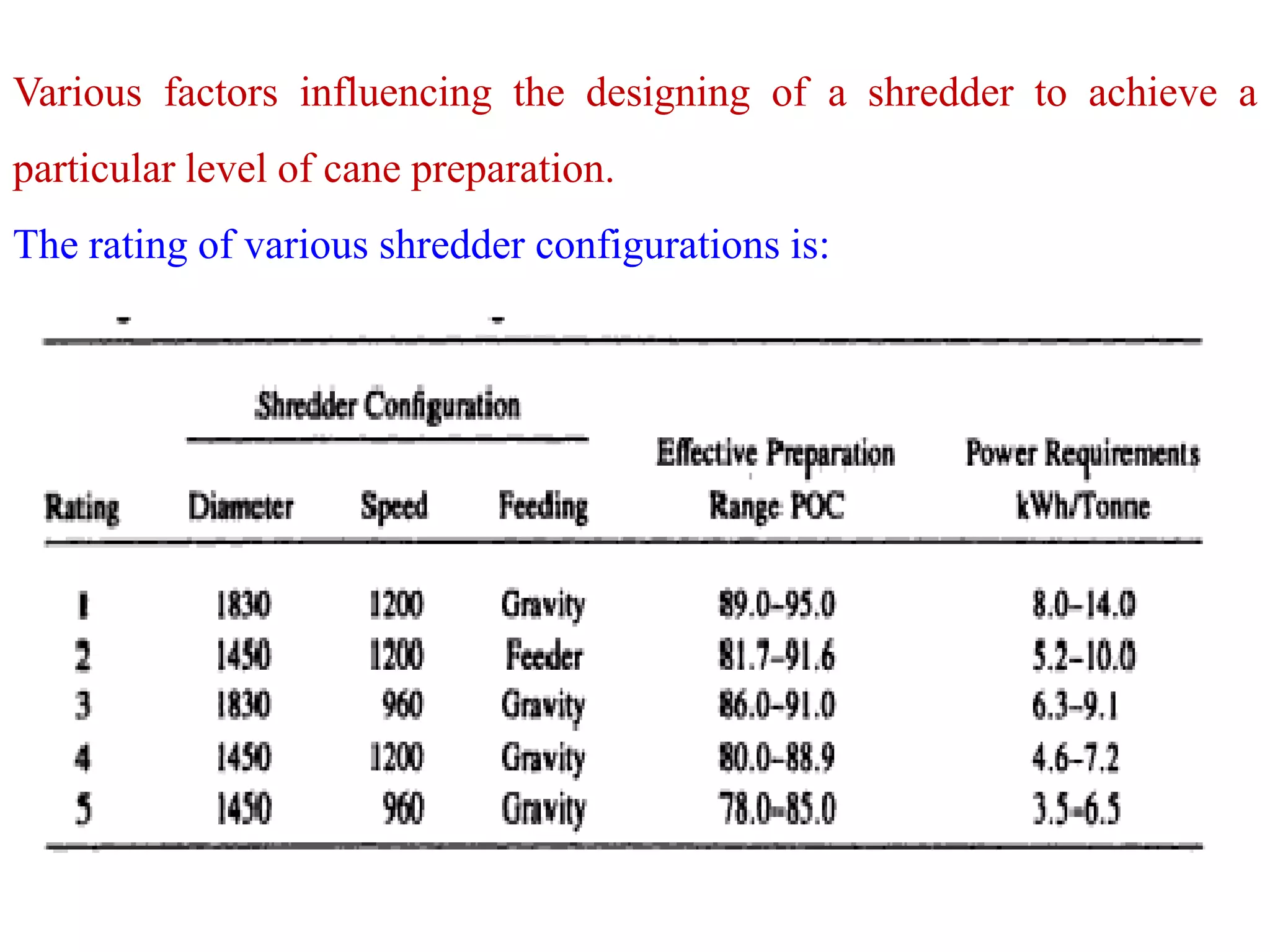

![Soil Preparation

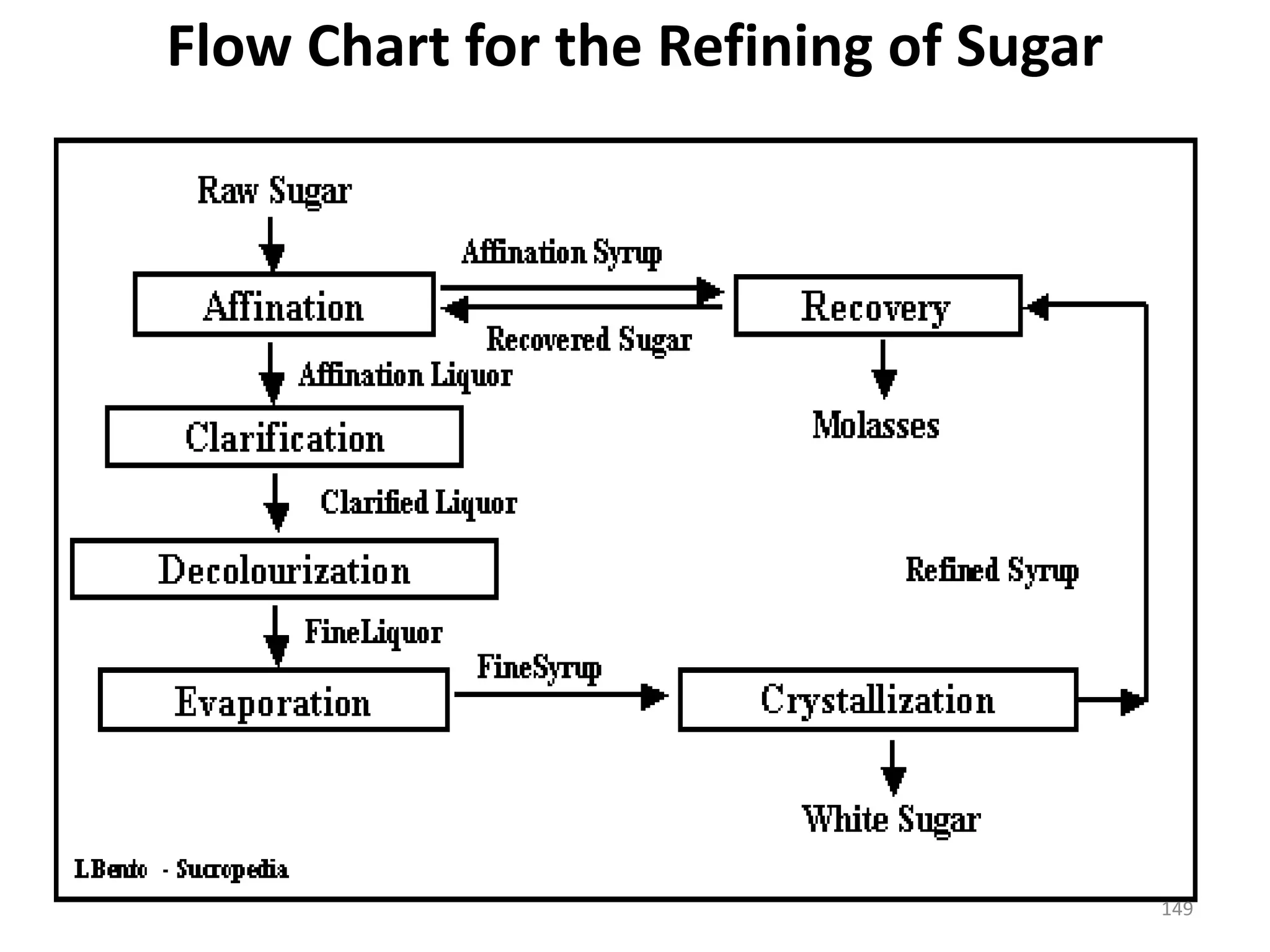

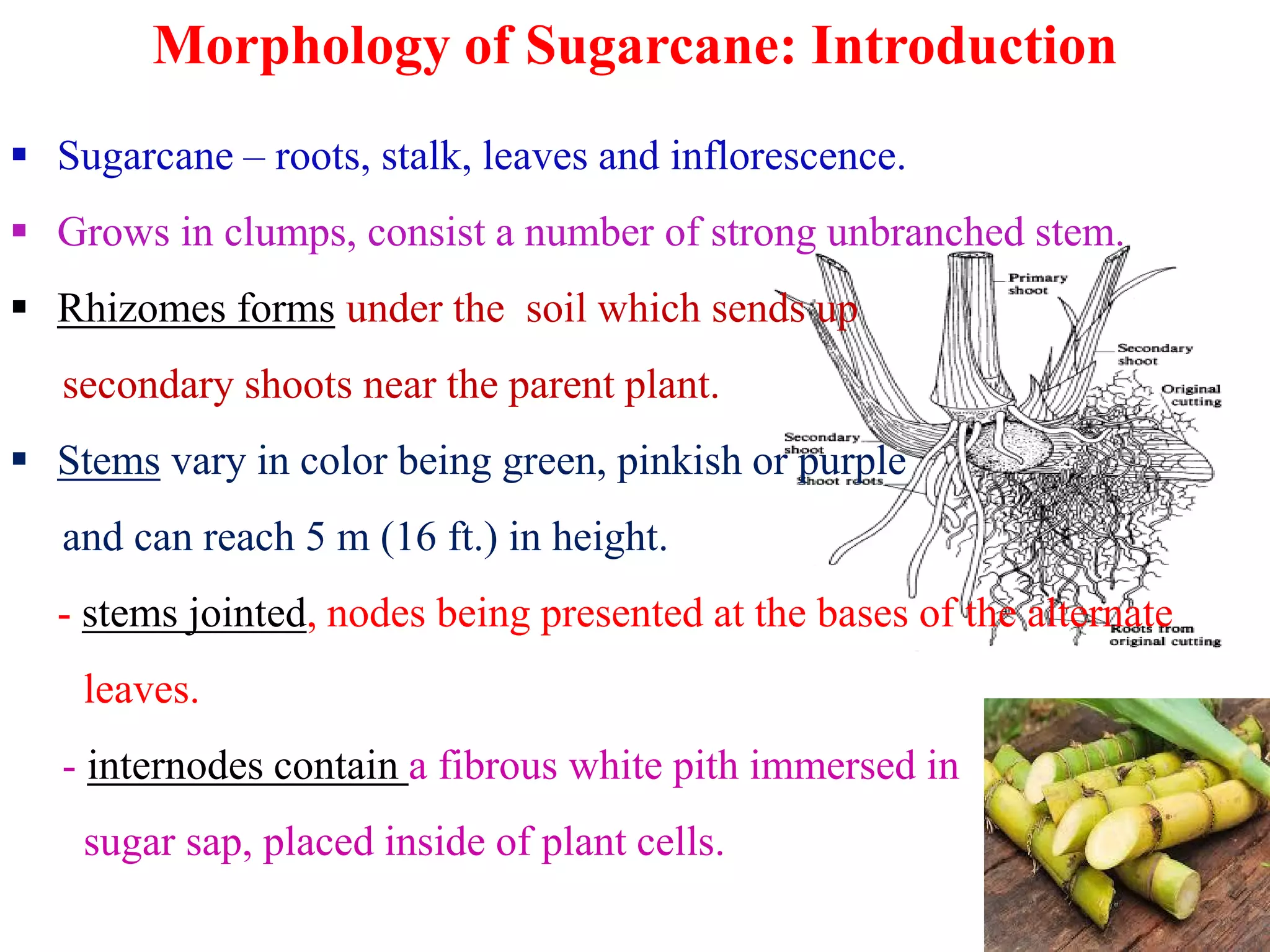

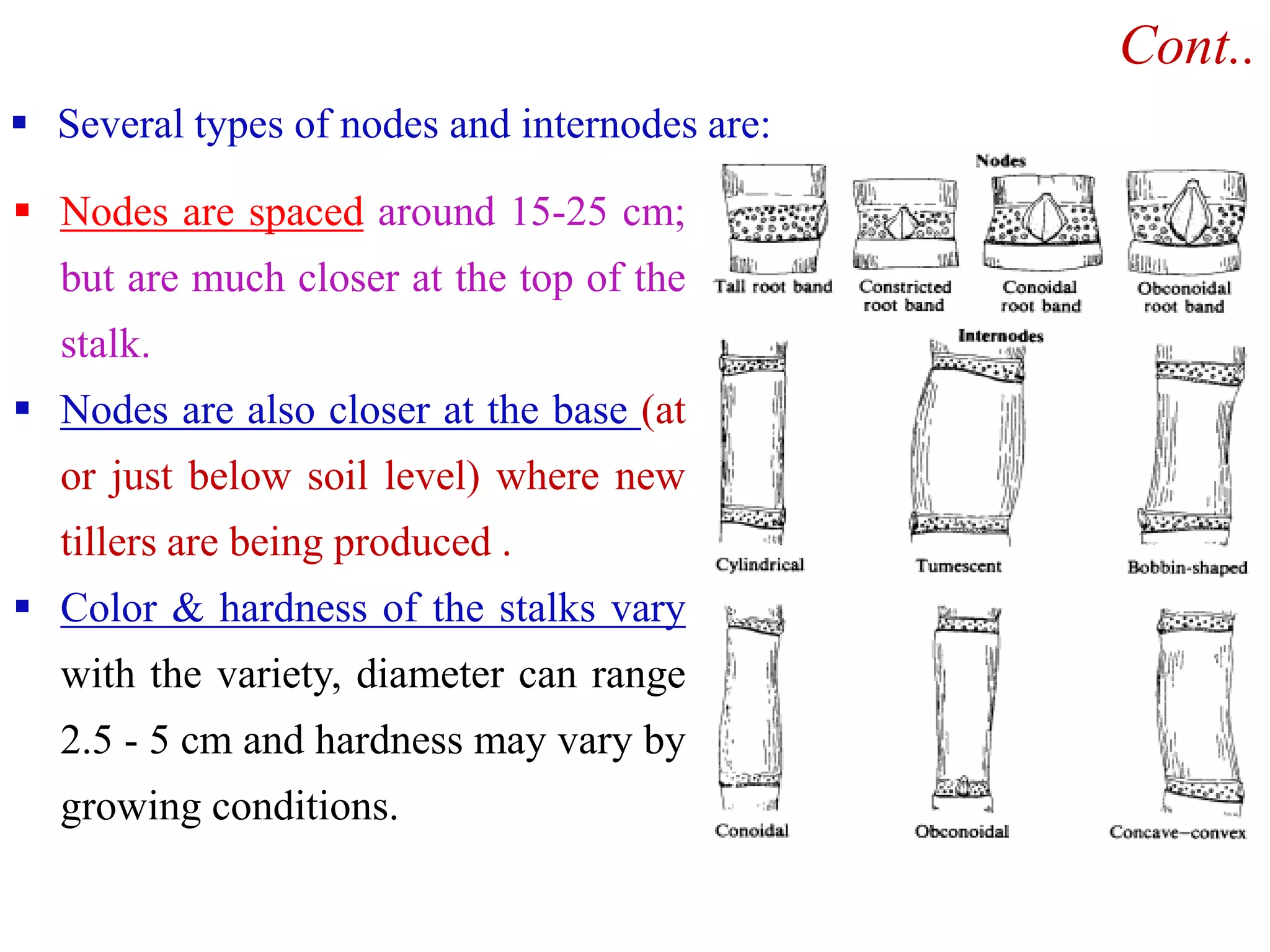

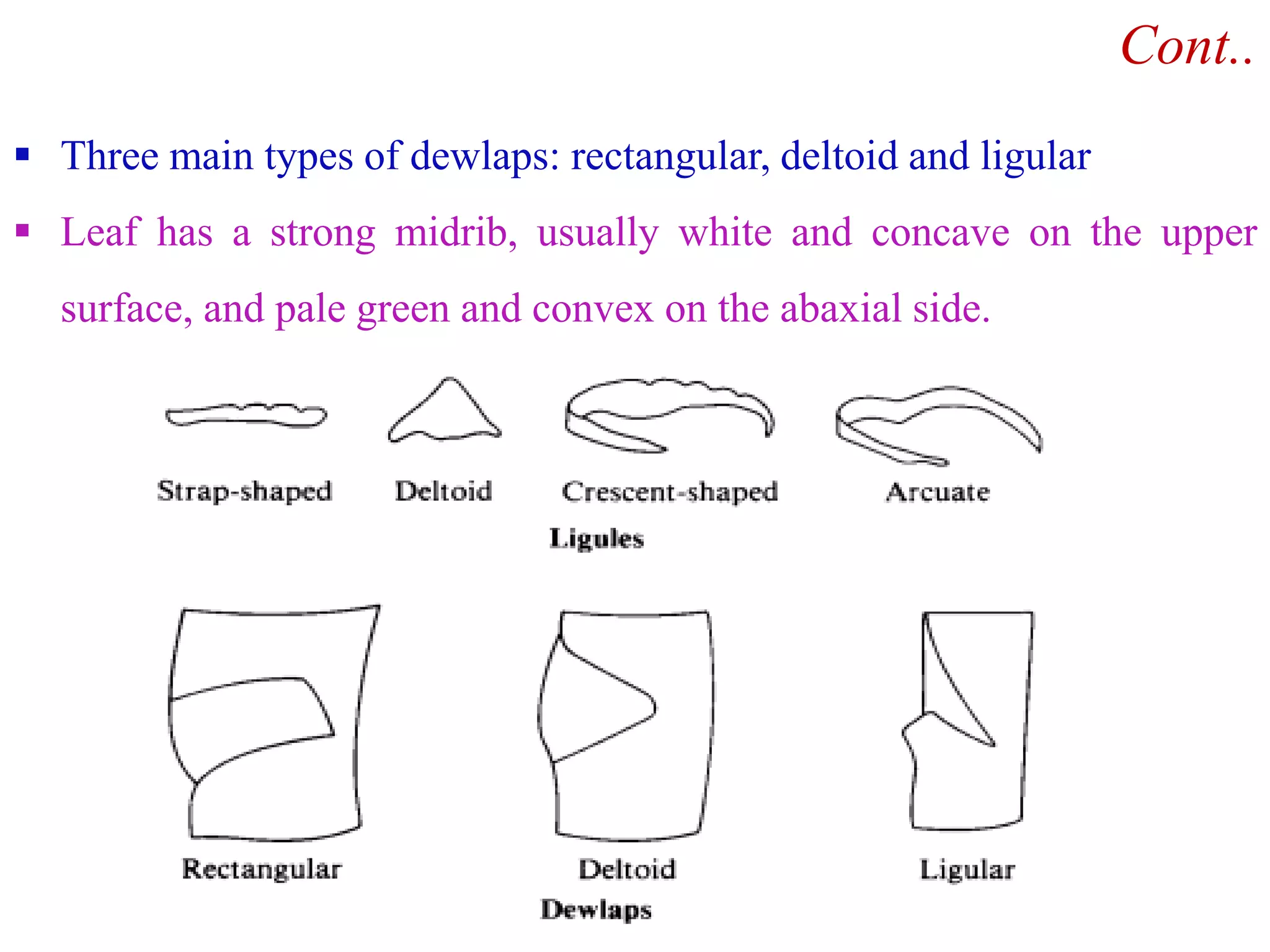

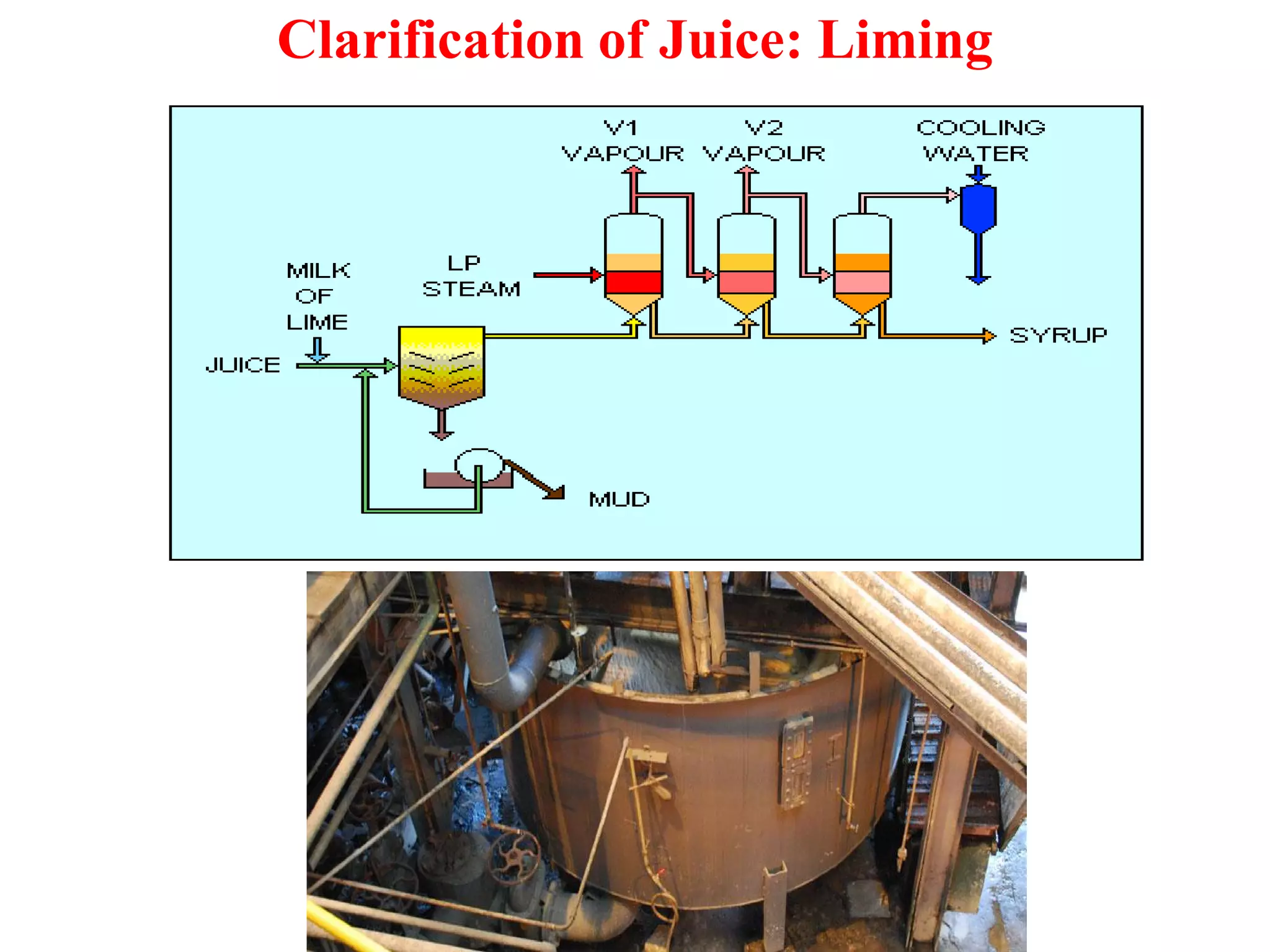

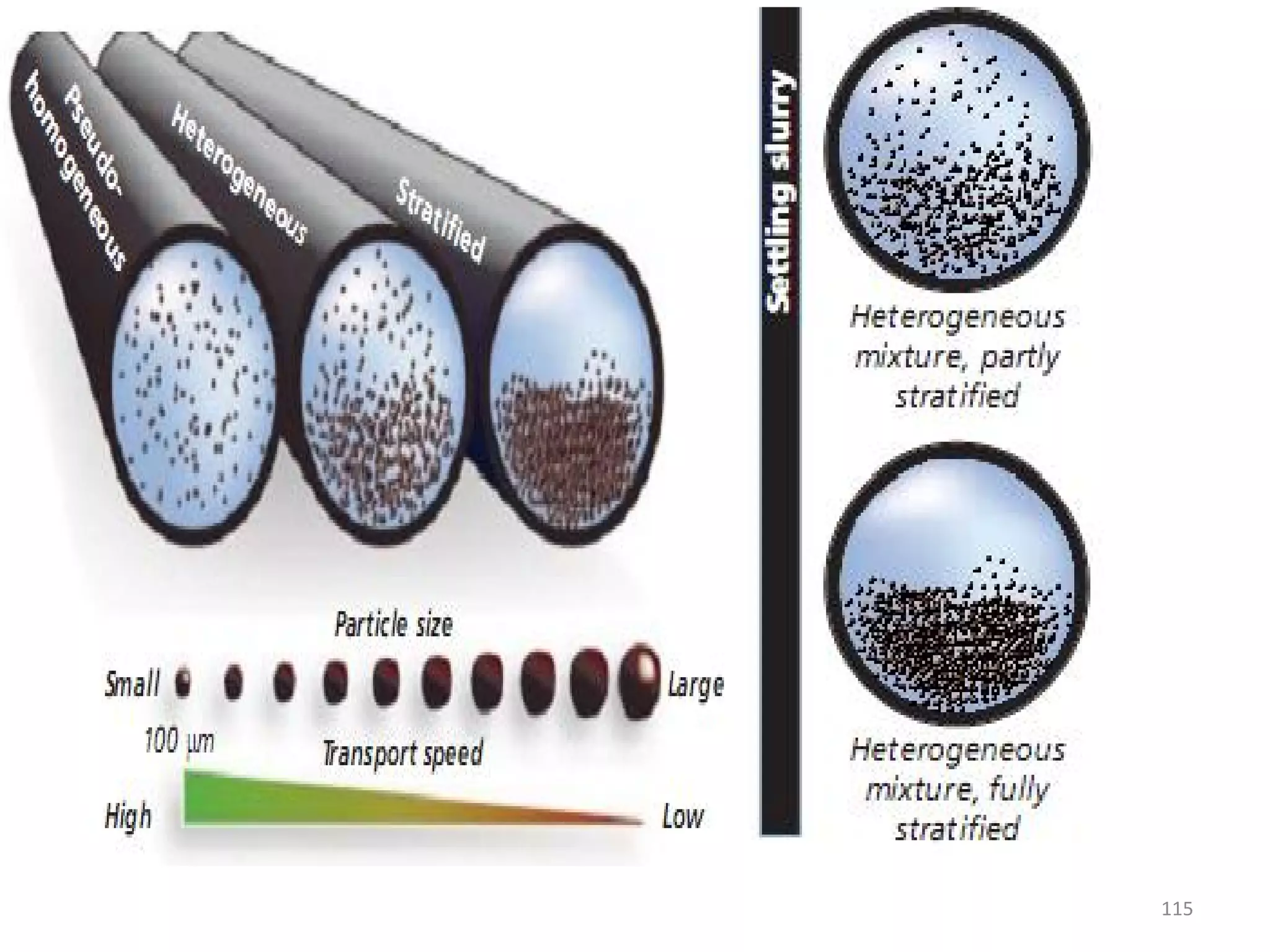

Steps in Land Preparation Involve the Following:

Sub-soiling to a depth of 50 to 75 cm to break hard compact sub-pan

layer. Breakage of hard pan muse be necessary.

Ploughing to incorporate previous crop's residues and organic

manures [5-6 ploughings with atleast 2 planking's, must go 20-25 cm deep]

Field layout: construct ridges & furrows and shape them.

Depth of furrows should be 25 cm. The furrow bottom should be

loosened to about 10 cm.

Provide drainage channels, which are deeper than the furrows.

Drainage channels are particularly important in the high rainfall areas

to drain the excess water during rainy season.](https://image.slidesharecdn.com/basicsofsugartechnology-180718062420/75/Basics-of-sugar-technology-36-2048.jpg)

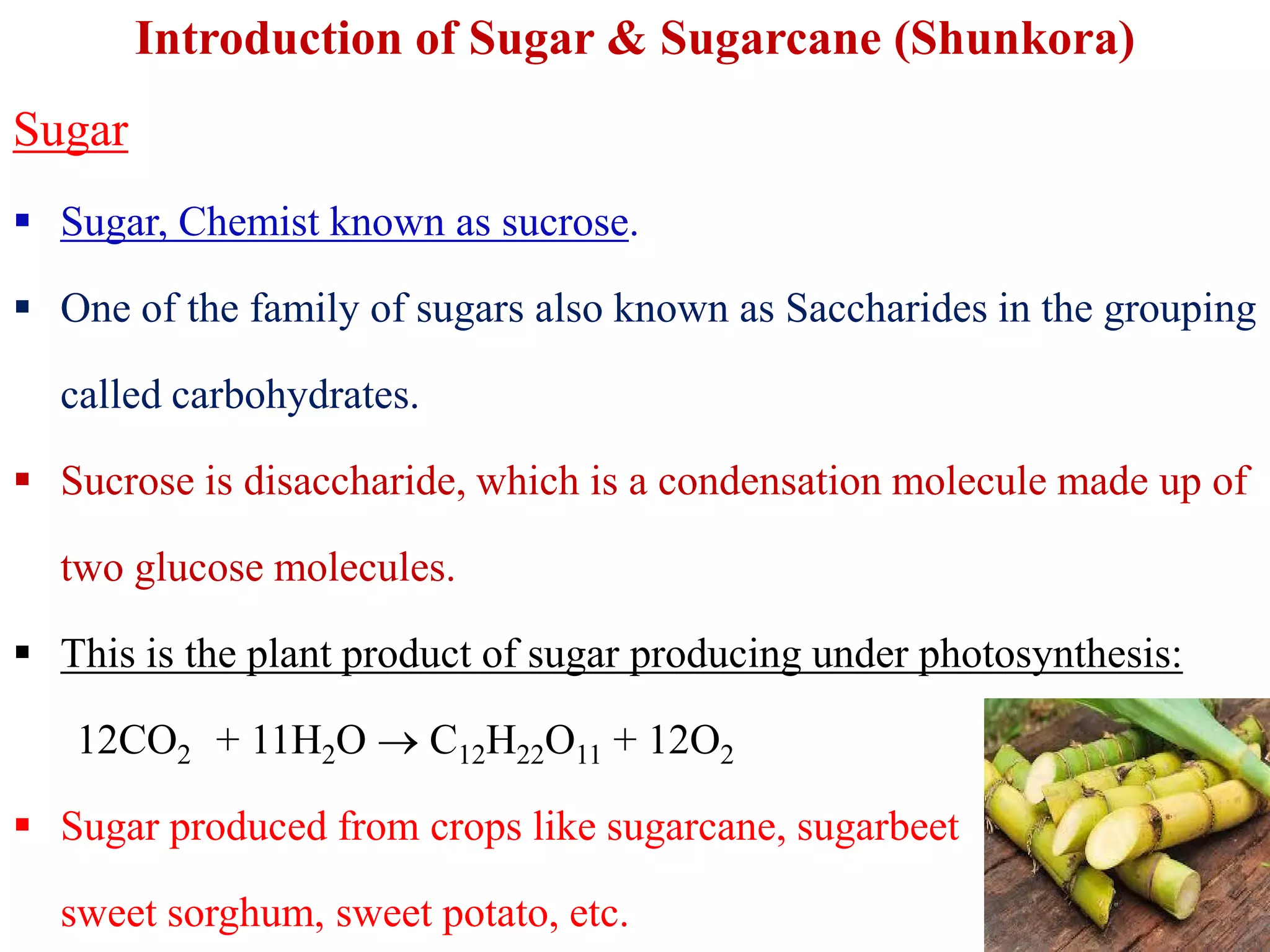

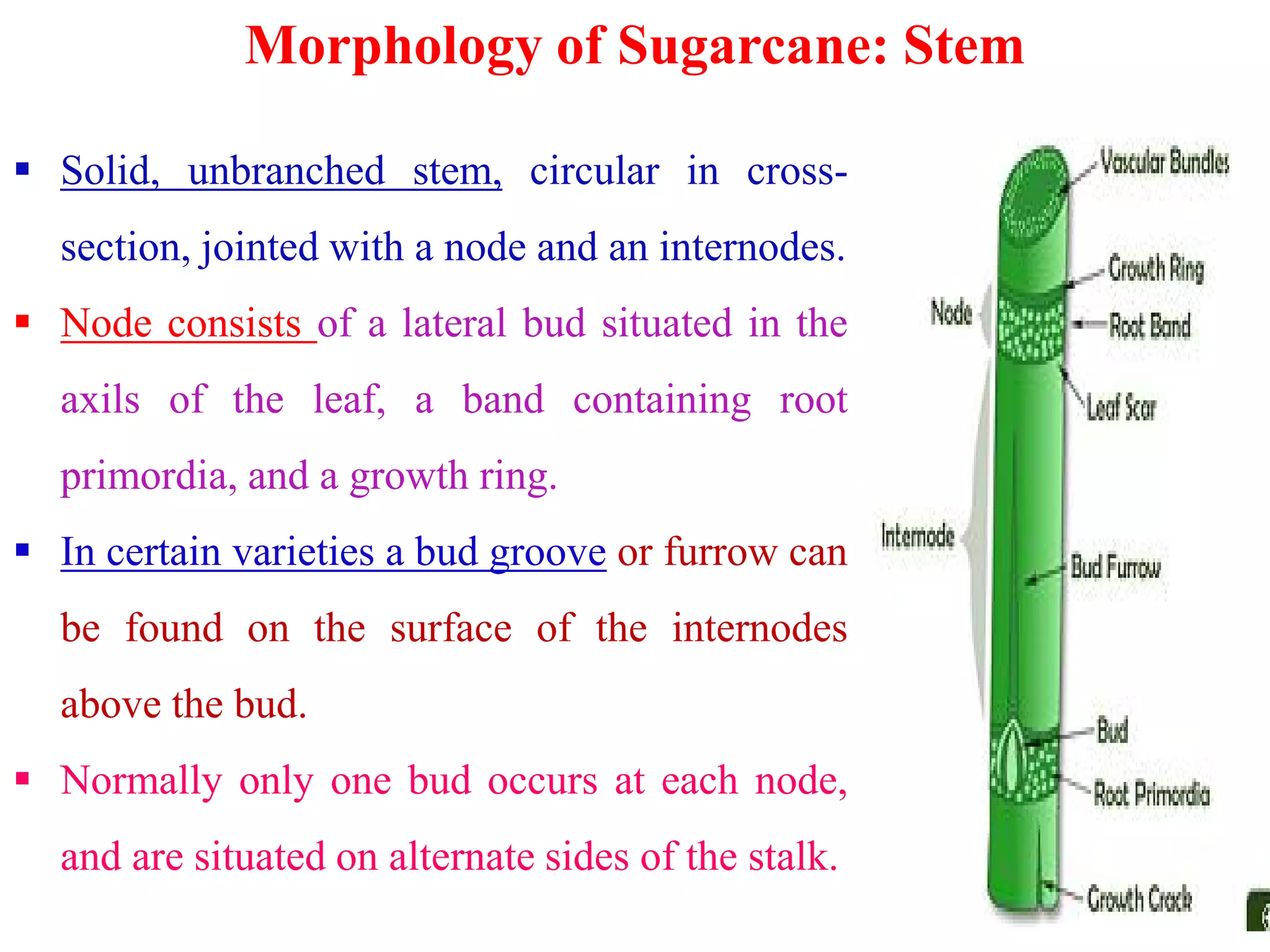

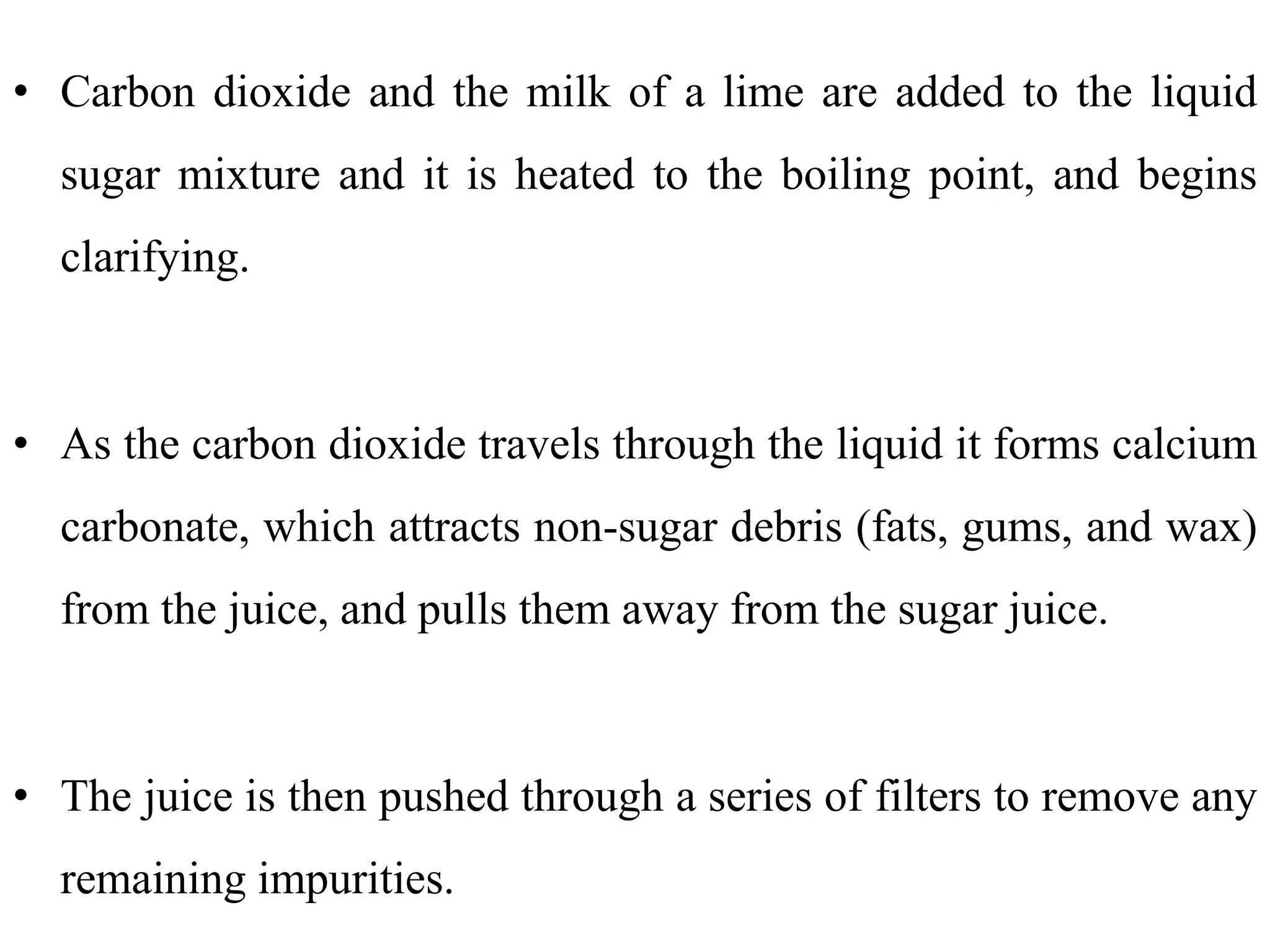

![Melting: The affinated sugar is dissolved with hot condensate to a liquid

approximately 72º Brix at 75ºC.

Purification: Remelt may contain some impurities and colorants must

remove by,

- Liming

1. Partial 2. Complete

- Carbonization- Carbonization

- Colorants remover by decolorization

Carbonation: Processing the liquor, aimed to removing the solids which

make the liquor turbid.

It is achieved by adding milk of lime, [Ca (OH)2] to the

liquor and bubbling carbon dioxide through the mixture.

Also it is the purpose to removing of further impurities that precipitate

from solution with calcium carbonate. 144](https://image.slidesharecdn.com/basicsofsugartechnology-180718062420/75/Basics-of-sugar-technology-144-2048.jpg)