The document summarizes the manufacturing process for sugar from sugar cane. Key steps include:

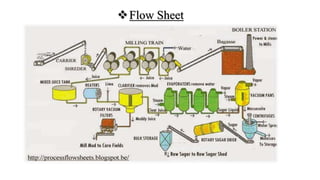

1) Crushing sugar cane and extracting juice through a series of pressure mills.

2) Treating the juice with lime and sulfur dioxide to precipitate impurities.

3) Heating and clarifying the juice in an evaporator to concentrate it for crystallization.

4) Separating sugar crystals from syrup using centrifugal separation. Bagasse is used as fuel.