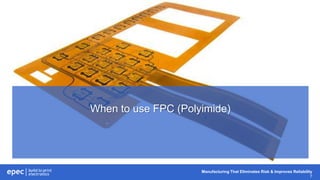

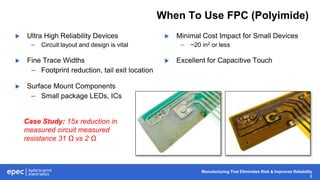

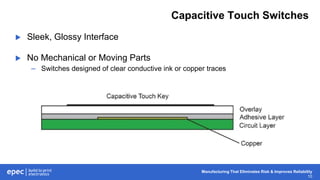

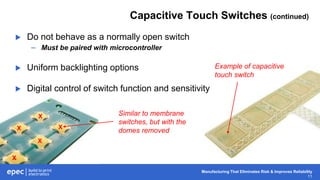

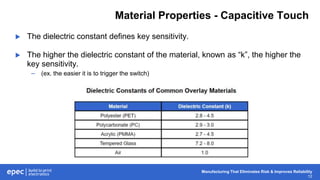

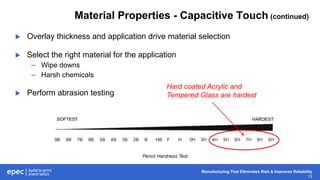

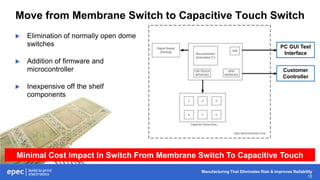

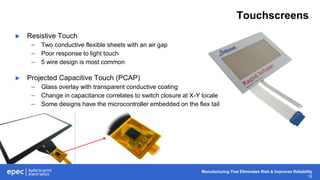

The document discusses advancements in human-machine interface (HMI) technologies, comparing old and new generation technologies while emphasizing the benefits of capacitive touch and smart devices. It highlights key material properties, design considerations, and cost-effective options that improve reliability and user experience. The presentation concludes by encouraging the use of modern technology to customize and enhance product interactions.