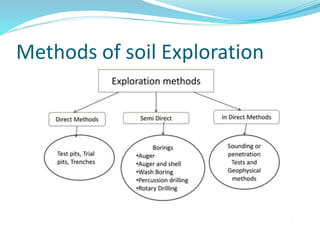

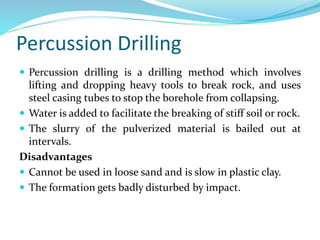

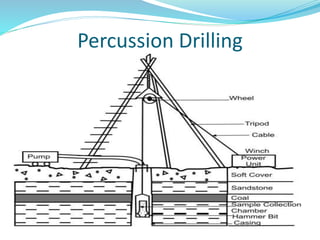

Subsoil exploration involves laboratory and field investigations to assess soil properties at a site. It determines the nature, depth, and thickness of soil strata as well as groundwater conditions and engineering properties. Methods include test pits, boreholes using augers or drilling, in-situ tests like SPT and CPT, and geophysical methods such as seismic refraction and electrical resistivity testing. The results are used to select appropriate foundation types and determine bearing capacity.