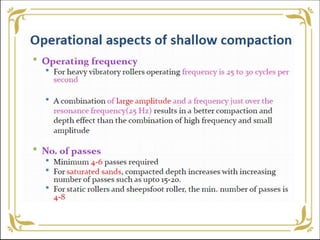

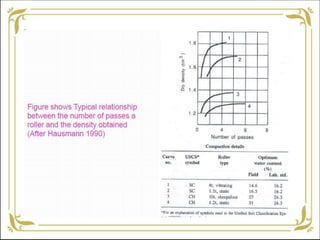

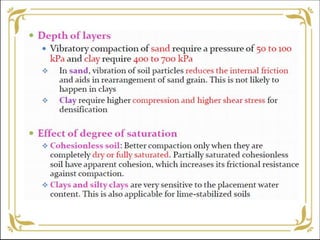

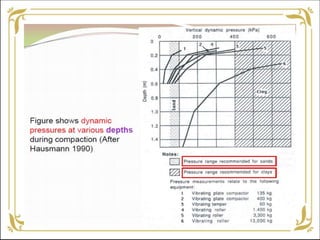

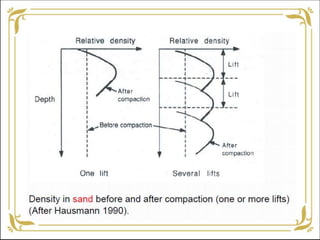

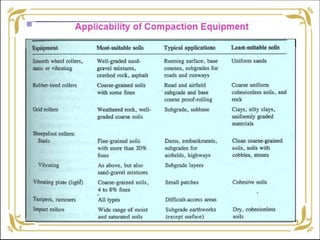

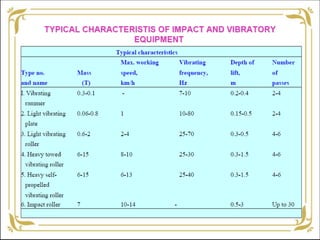

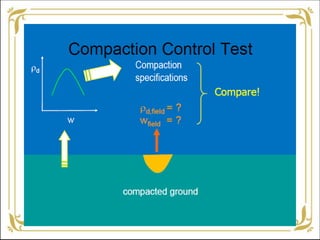

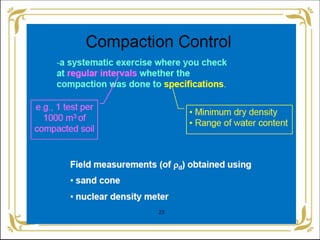

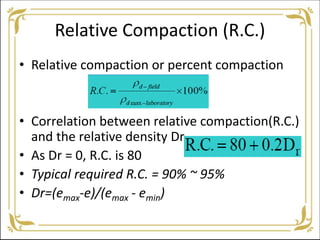

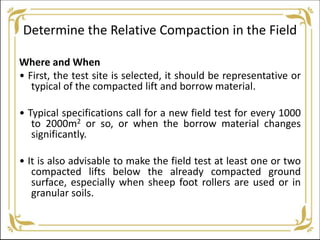

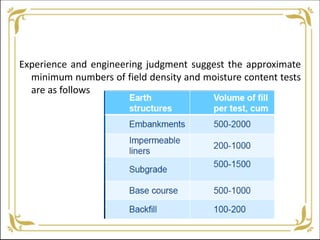

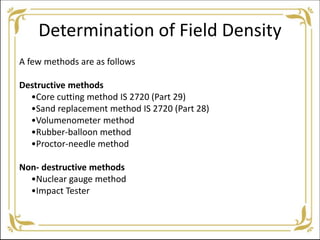

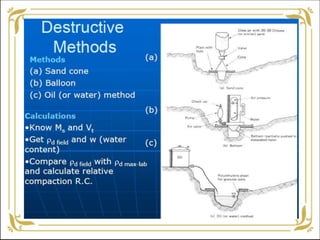

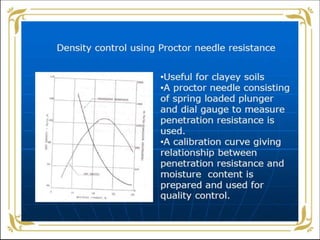

The document discusses various approaches to specifications and quality control in soil compaction, emphasizing the importance of relevant control tests that relate density and water content to stability and cost-effectiveness. It outlines suitable soil types for compaction, as well as different compaction control tests and procedures, including laboratory and field testing methods. The content covers specifications related to end-product and method specifications, indicating the significance of relative compaction in achieving desired engineering outcomes.