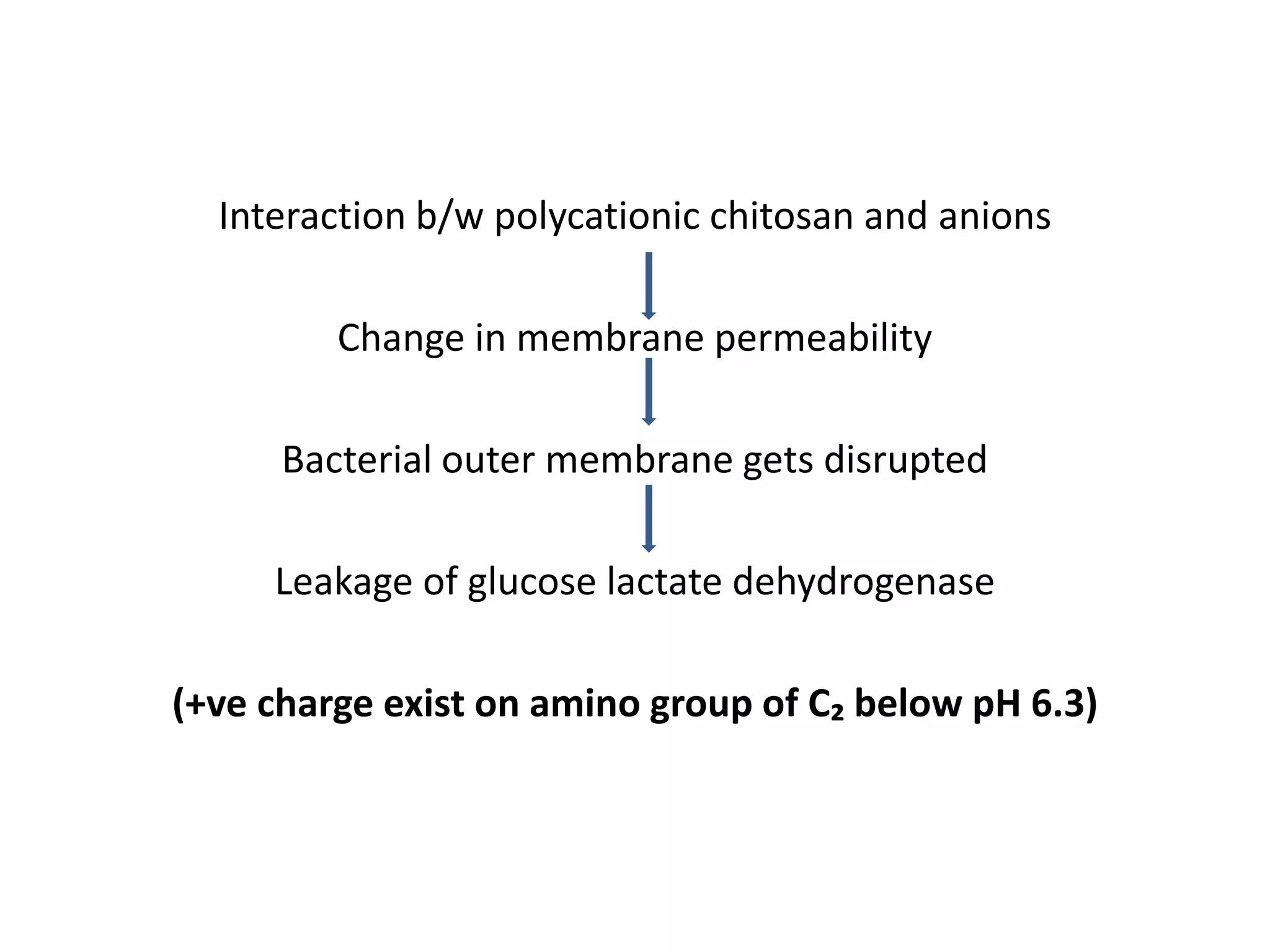

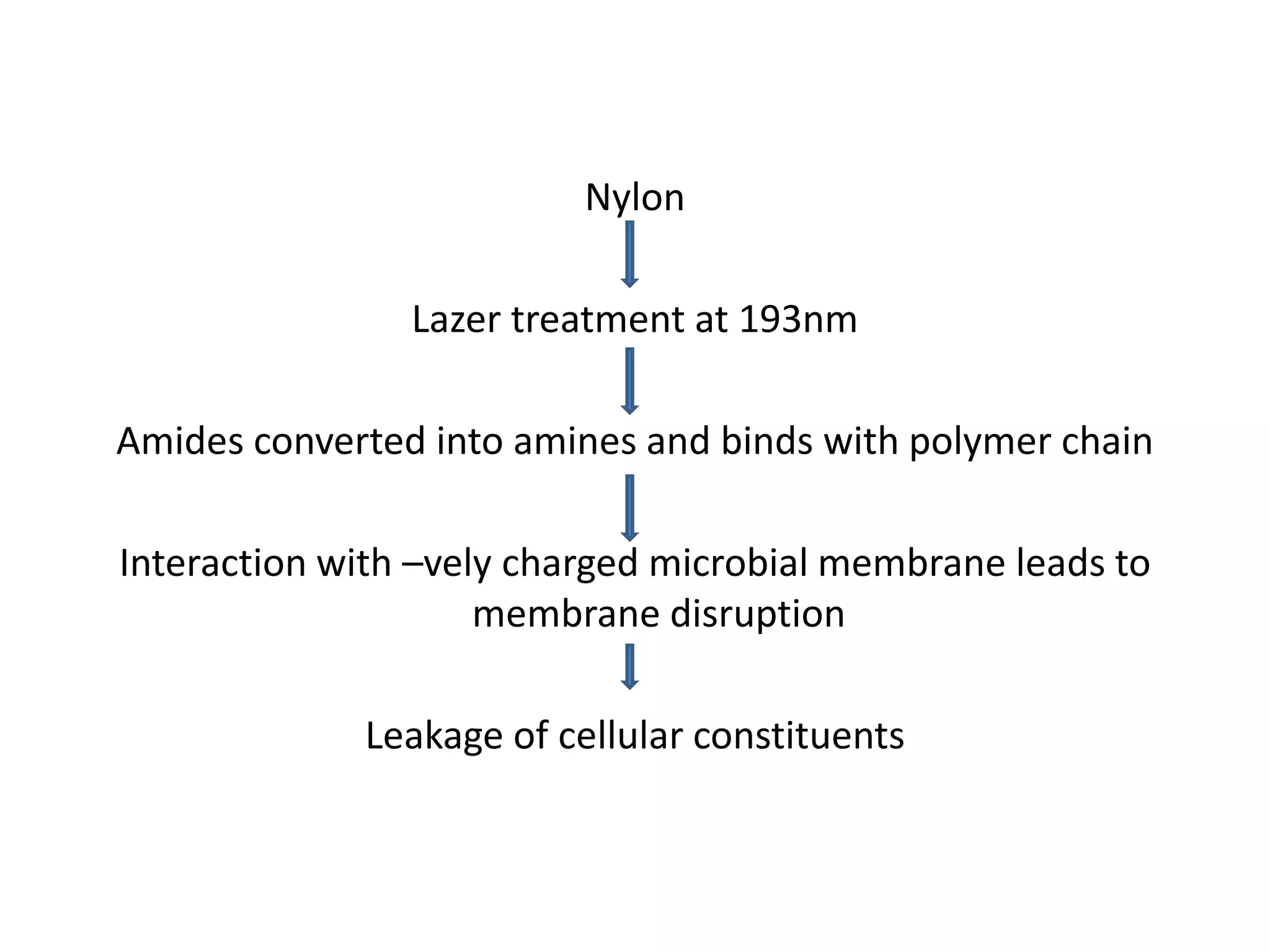

This document discusses non-migratory bioactive polymers for food packaging. It provides examples of how bioactive peptides and antimicrobial peptides can be covalently linked to packaging polymers to inhibit microbial growth without migrating into the food. Specifically, it mentions how chitosan, UV-irradiated nylon, and nylon treated with laser can all exhibit antimicrobial properties through interactions with microbial membranes that disrupt permeability. Non-migratory bioactive polymers provide benefits like improved stability of bioactive compounds, regulatory advantages over food additives, and enabling minimally processed foods with a longer shelf life.