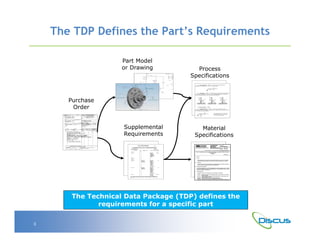

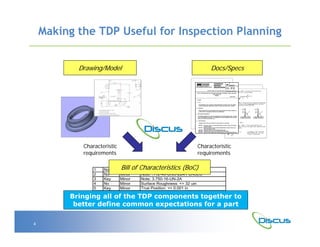

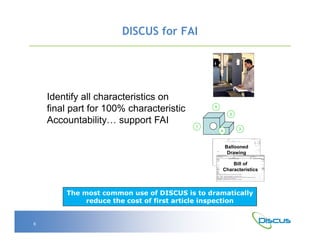

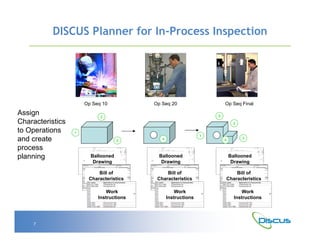

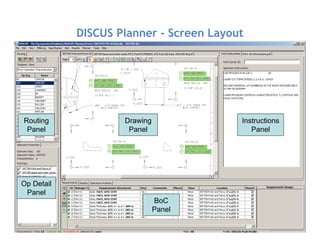

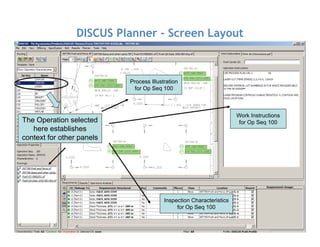

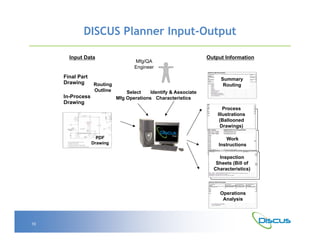

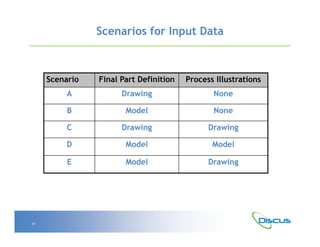

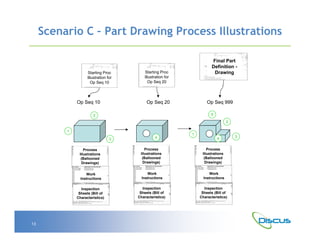

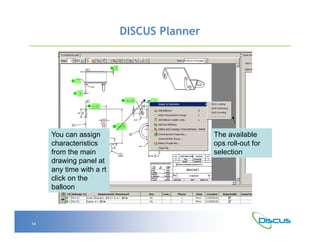

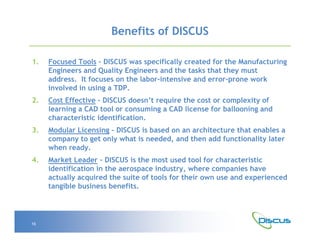

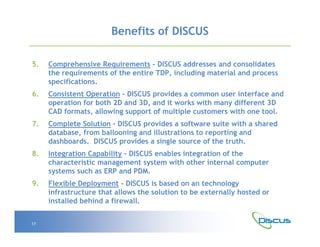

The document discusses the use of the DISCUS software for in-process inspection planning, emphasizing its role in managing technical data packages (TDP) to ensure part specifications are met throughout manufacturing. Key features include cost-effectiveness, modular licensing, and integration capabilities with other systems, making it a preferred tool in the aerospace industry. It highlights the software's ability to streamline processes and improve characteristic accountability during inspections.